Full-automatic pipeline glazing system for ceramic closestool

A toilet, fully automatic technology, applied in the field of automatic pipeline glazing system for ceramic toilets, can solve problems such as unfavorable automatic docking, uneven glazing, incomplete glazing, etc., to ensure integrity, ensure consistency, and avoid pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

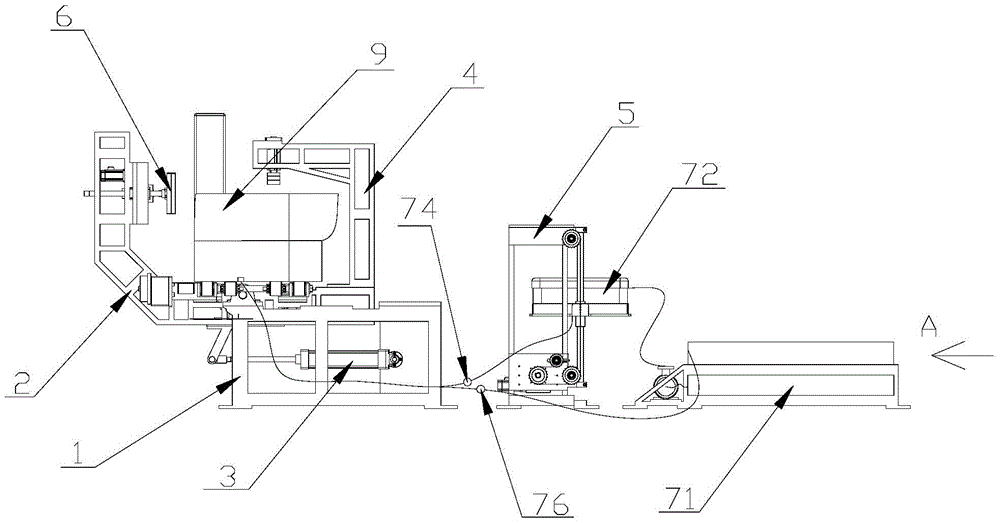

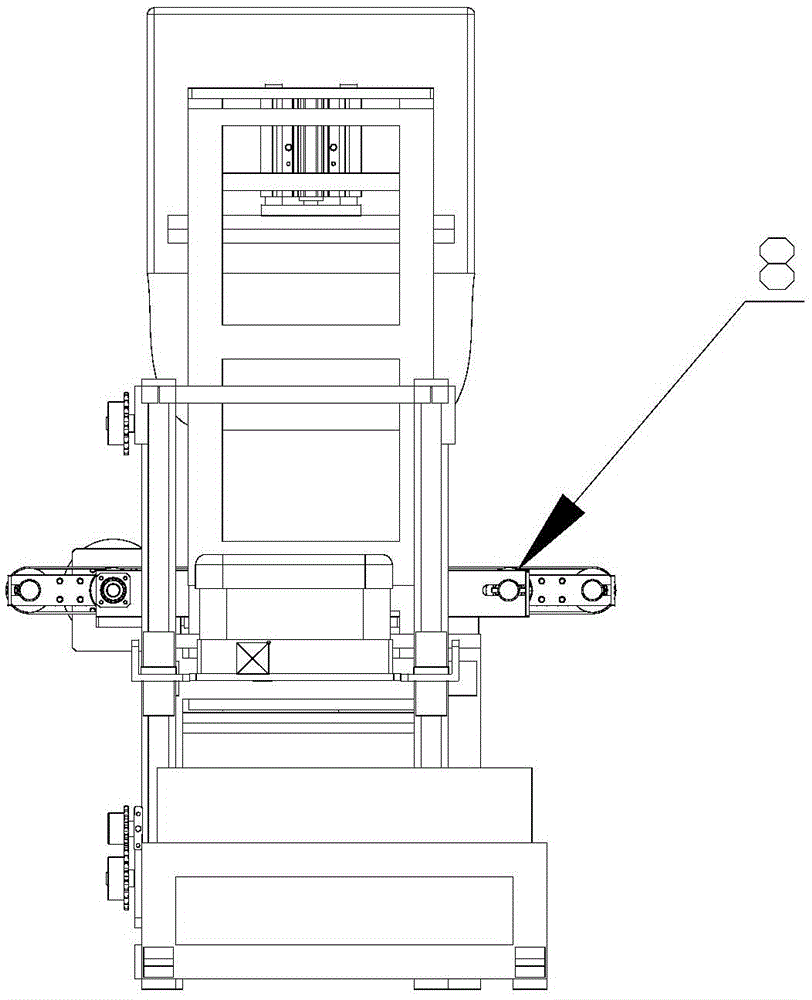

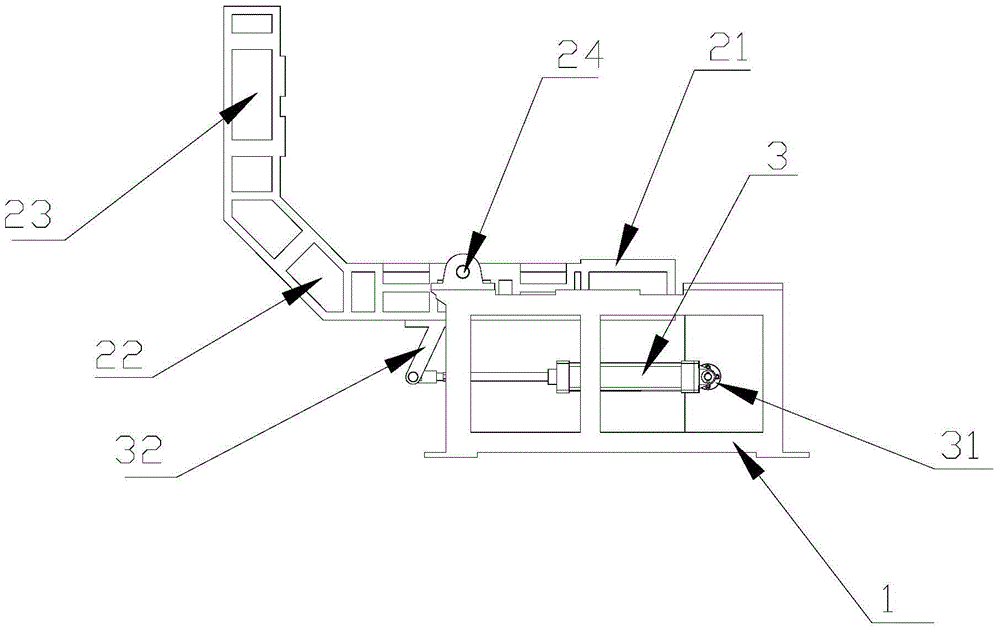

[0049] Please refer to figure 1 with figure 2 As shown, a fully automatic pipeline glazing system for ceramic toilet, which mainly includes: support 1, embryo body rotating frame 2, first telescopic cylinder 3, locking mechanism, conveying butt joint 8, glaze supply box 72, glaze supply box Lifting mechanism 5. Among them, the embryo body rotating frame 2 is rotatably connected to the support 1, and is used to drive the embryo body 9 on it (that is, the ceramic toilet embryo body) to perform pipeline glazing during the rotation process; the first telescopic cylinder 3 is installed on the support 1 upper, used to drive the rotation of the embryo body rotating frame 2; the locking mechanism is fixedly installed on the embryo body rotating frame 2, and is used to act on the rear part of the embryo body 9 and the embryo body when it is transported to the glazing position of the pipeline glazing equipment On the upper surface of the seat ring, so as to realize the positioning an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com