Measuring method

A measurement method and a technology of measuring rods, which are applied in the field of measurement, can solve problems such as the influence of electrode rod size, ultrasonic propagation interference, and unchanged operation, so as to achieve the effects of improving formation quality/purity, improving formation quality, and reducing influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

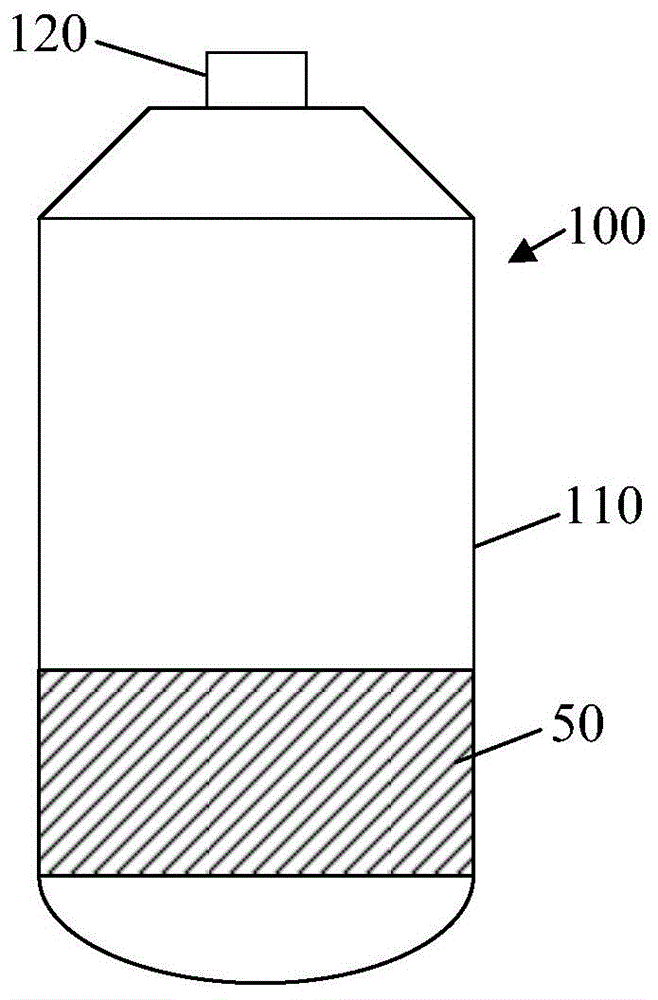

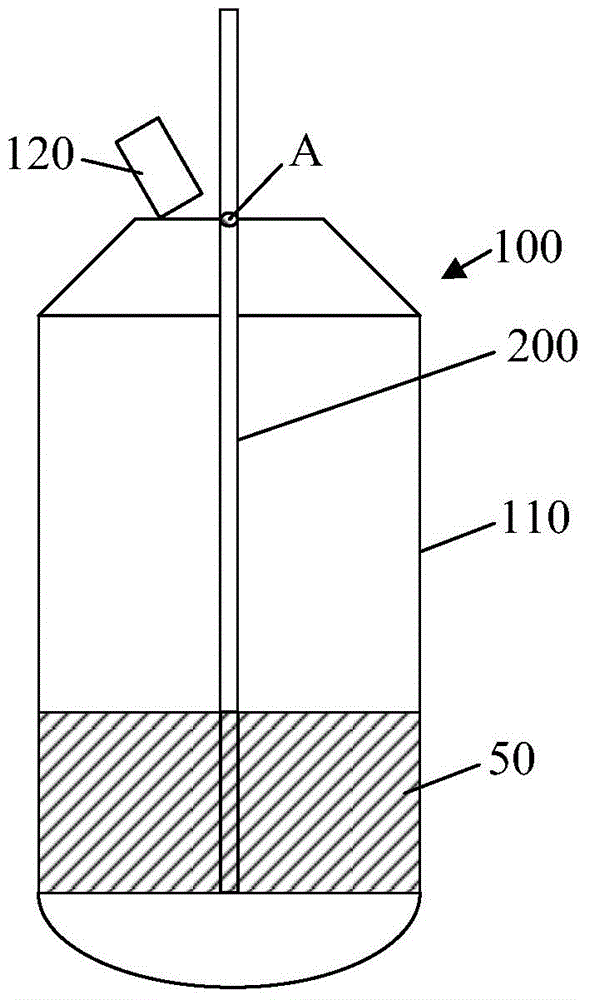

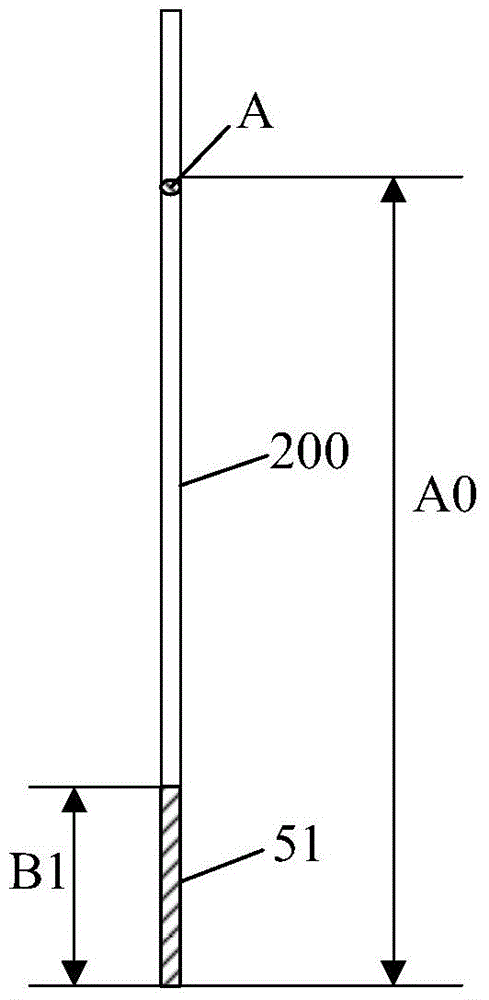

[0047] In the molten salt electrolysis process, it is necessary to measure the height of the liquid level of the molten salt and the height of the electrolytic solid, and then set the length of the electrode rod used according to these data. However, the existing technology is difficult to perform accurate measurement. For example, the method of measuring the liquid level of the molten salt by ultrasonic positioning the position of the float is easily affected by the complex structure of the molten electrolysis equipment itself, so it cannot be measured well. The size of the selected electrode rod does not meet the requirements, and the quality of the electrolytic product is affected; at the same time, because the molten salt itself is highly corrosive, the float placed on the molten salt for a long time will also be corroded to a certain extent, and impurities will be mixed into the molten salt. , which will affect the purity of the electrolysis product.

[0048] Therefore, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com