A bubble electrospinning system for preparing composite fiber materials

A technology of bubble electrospinning and composite fiber, which is applied in the field of spinning, can solve the problems of reduced spinning efficiency, mutual influence of bubbles, and inability to mix the spinning solution completely and uniformly, so as to avoid the mutual influence of bubbles and increase the output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

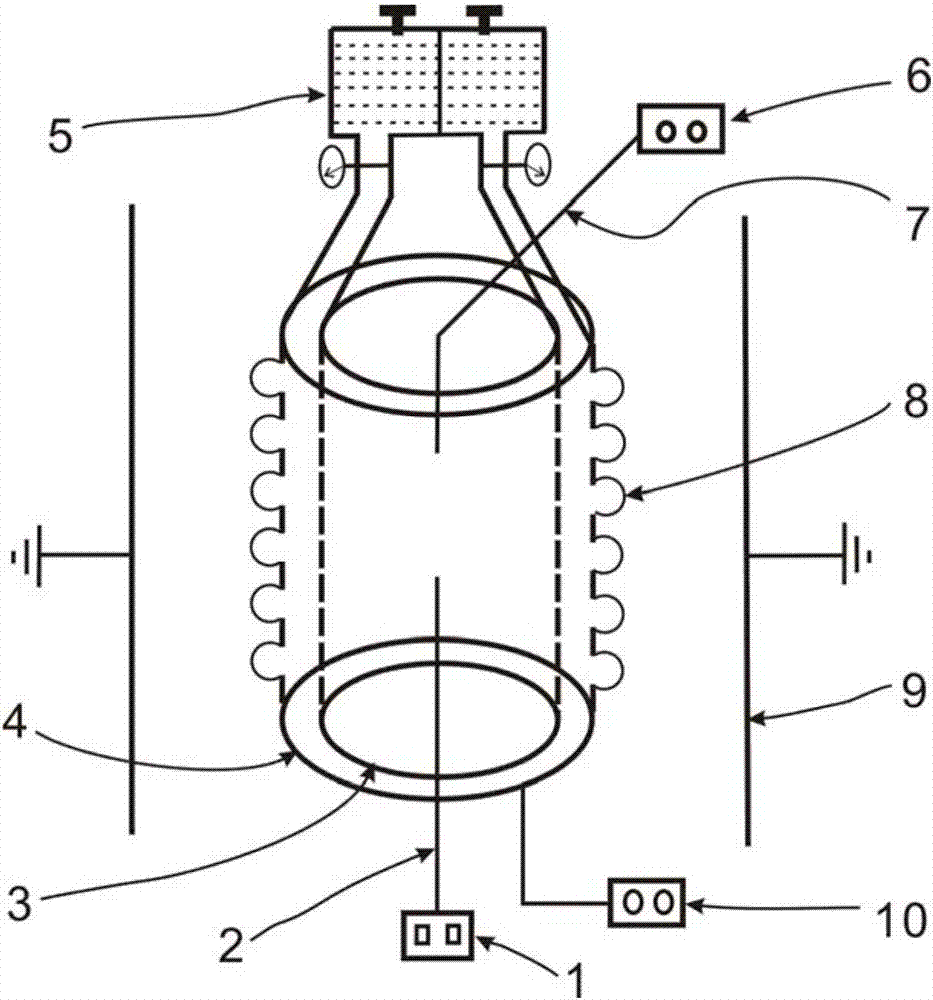

[0036] In the current bubble electrospinning technology, when the composite fiber material is prepared, the spinning solution is exposed to the air, which leads to the change of the solution properties and reduces the spinning efficiency. The interaction of multiple bubbles leads to the Taylor cone interaction caused by the bubble rupture. Different properties and different Functional solutions cannot be mixed completely and evenly, which leads to the inability to realize larger-scale batch production of micro-nano composite fiber materials.

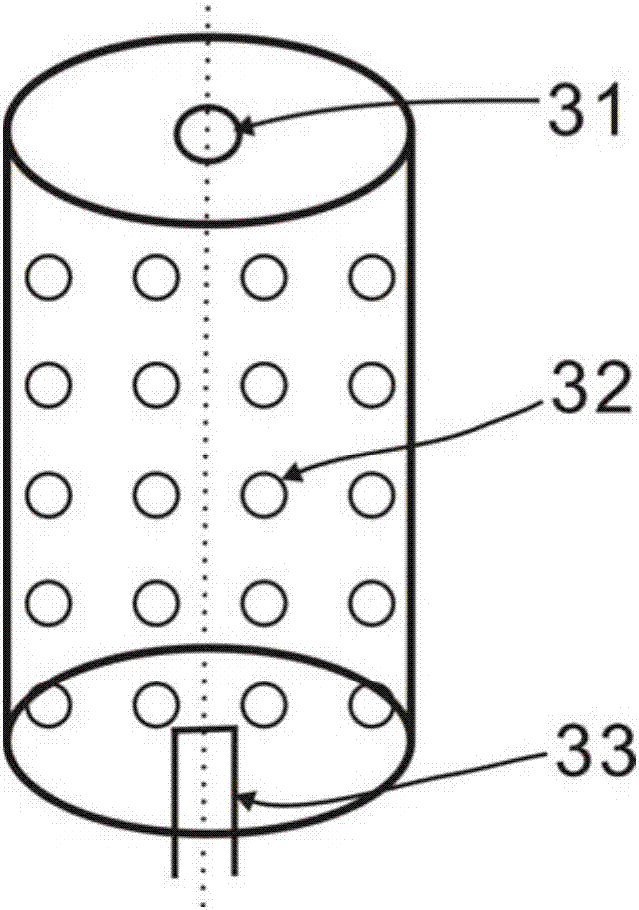

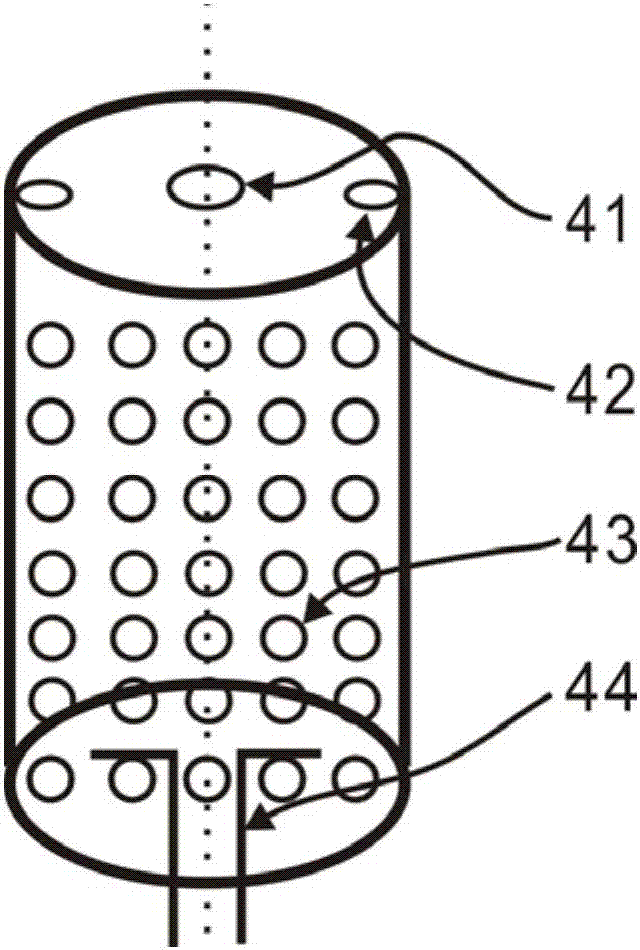

[0037] Aiming at the deficiencies in the prior art, the present invention provides a bubble electrospinning system for preparing composite fiber materials. By adopting inner and outer nested spinning cylinders and air storage cylinders as spinning devices, different solutions are separately set and passed through The single infusion pipeline is transported between the closed spinning cylinder and the air storage cylinder, and the solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com