Prefabricated concrete beam-column joint using medium-strength prestressed tendons

A medium-strength prestressed tendon and prefabricated concrete technology, which is applied in the direction of construction and building structure, can solve the problems of inconspicuous application advantages, inconvenient construction and insufficient applicability, and achieve the reduction of beam cross-section or steel consumption and the construction efficiency. The effect of reducing difficulty and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with specific embodiment, and with reference to accompanying drawing, the present invention will be further described:

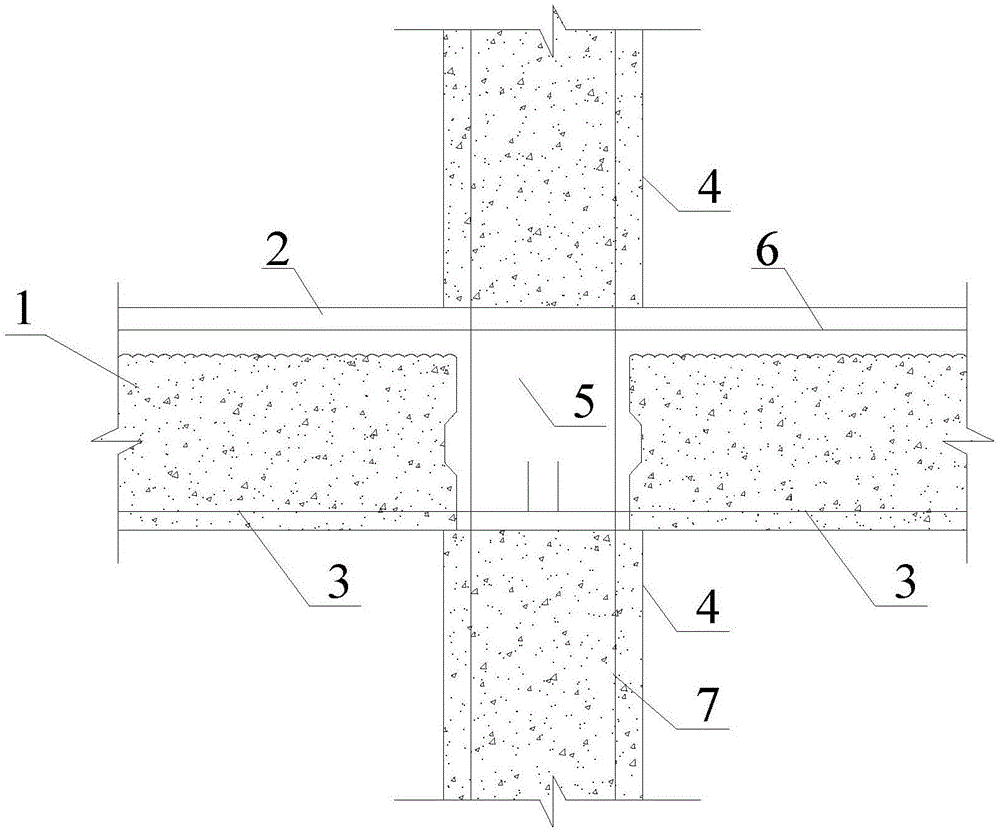

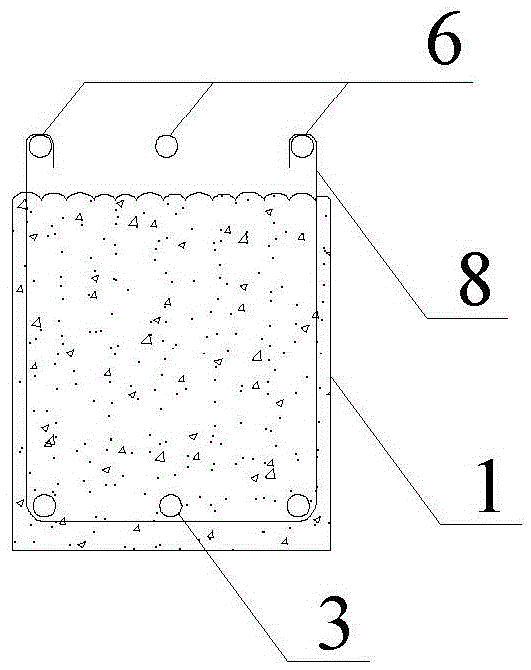

[0017] figure 1 It is a schematic diagram of the connection of prefabricated concrete beam-column joints adopting medium-strength prestressed tendons of the present invention, and figure 2 corresponding figure 1 Sectional view of the precast concrete beam and the upper part of the composite beam in the cast-in-place area. like figure 1 , figure 2 As shown, the precast concrete beam-column joints using medium-strength prestressed tendons include precast concrete beam 1, the upper part of the composite beam cast-in-place area 2, medium-strength prestressed tendons 3, precast concrete columns 4, post-cast section 5 in the joint area, Ordinary stressed steel bar 6 at the top of the beam and longitudinal steel bar 7 inside the column. figure 1 Among them, the bottom of the precast concrete beam 1 is only equipped with medium-str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com