A composite self-balancing bridge of an arch bridge and a suspension bridge and its construction method

A combined and self-balancing technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of material waste, structural stress, disadvantages, etc., to facilitate construction and installation, reduce structural weight, and overall structural safety high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

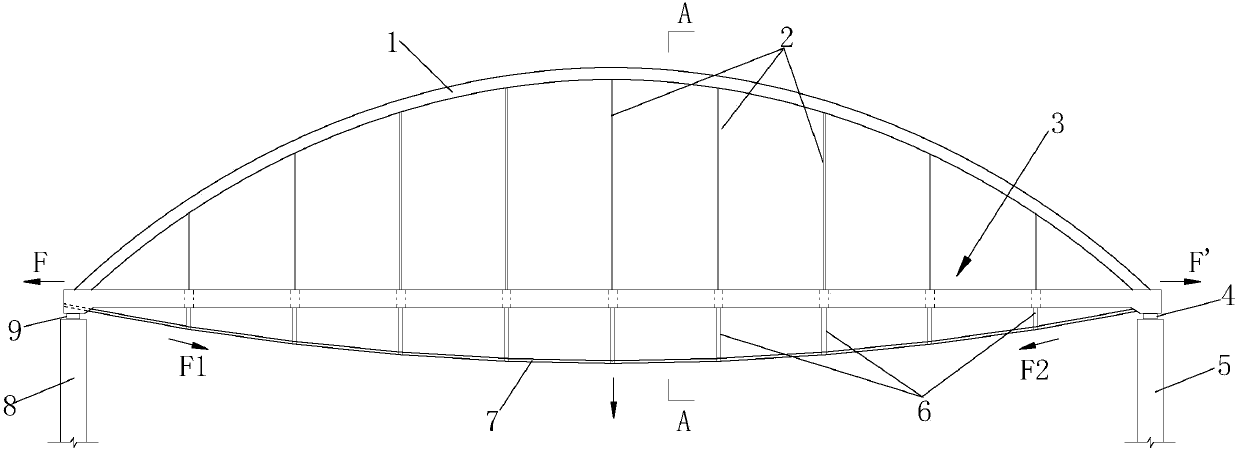

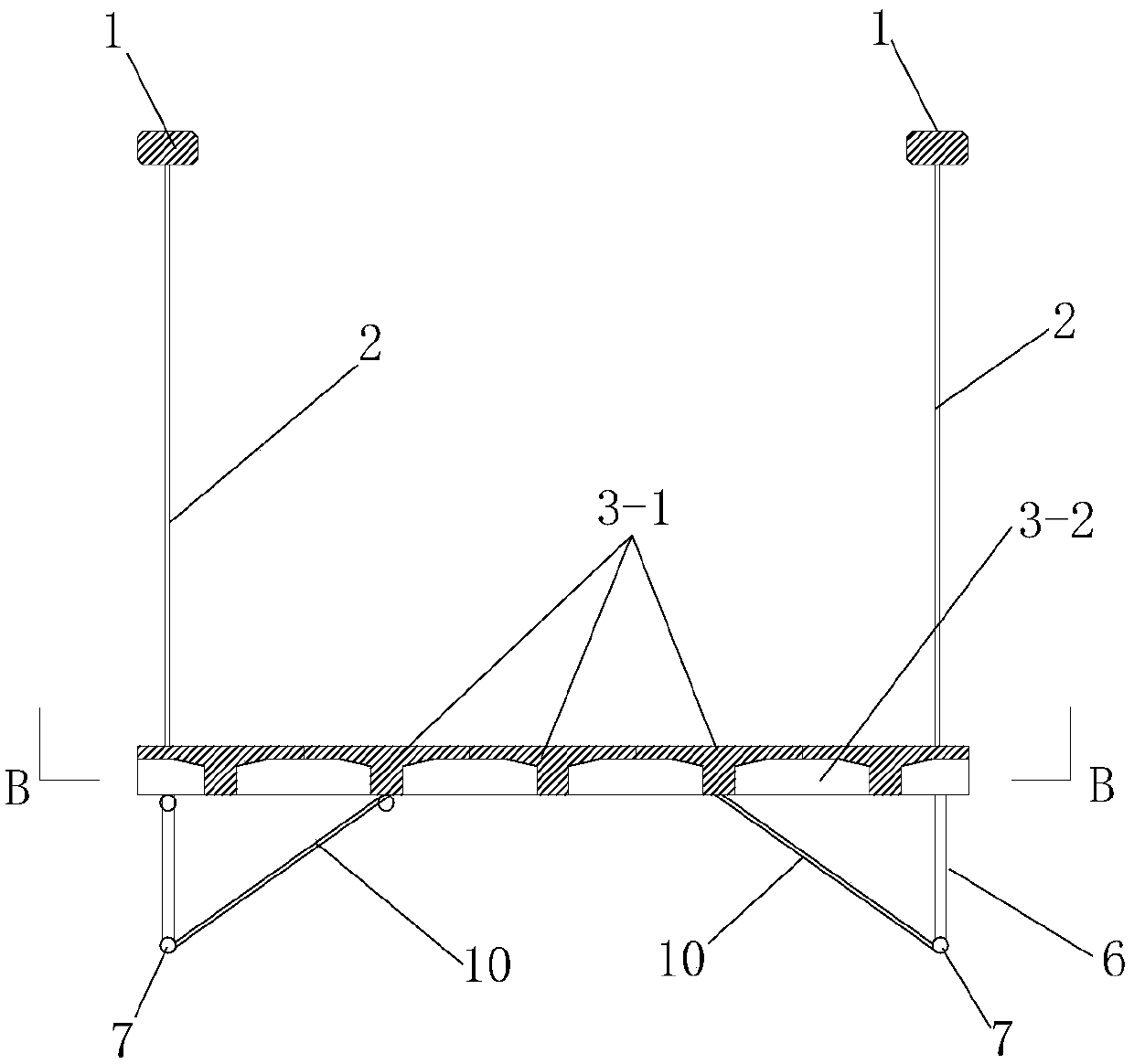

[0069] Such as figure 1 A combined self-balancing bridge of an arch bridge and a suspension bridge is shown, comprising a main girder structure 3, a bridge deck paved on the main girder structure 3, two arch rings 1 arranged above the main girder structure 3 and a Two main cables 7 below the main beam structure 3, one end of the main beam structure 3 is provided with a first bearing 4 for supporting it, and the other end of the main beam structure 3 is provided with a first support for supporting it. Two supports 9, one end of the arch ring 1 is fixed on one end of the main beam structure 3, the other end of the arch ring 1 is fixed on the other end of the main beam structure 3, and one end of the main cable 7 is fixed on the main beam One end of the structure 3, the other end of the main cable 7 is fixed on the other end of the main beam structure 3, the main beam structure 3 is connected to the arch ring 1 through the sling 2, and the main cable 7 is connected to the main be...

Embodiment 2

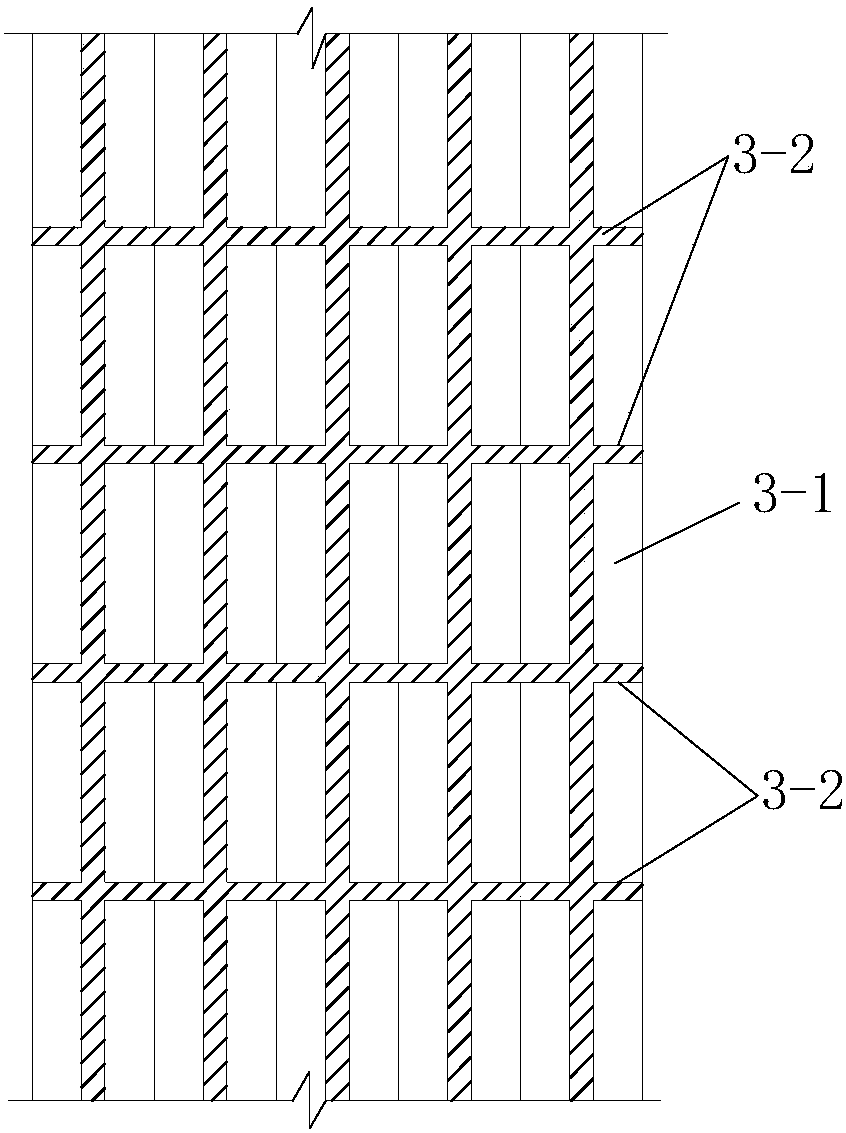

[0105] Such as Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that: the main beam structure 3 includes two longitudinal beams 3-1 and a plurality of cross beams 3-2 arranged between the two longitudinal beams 3-1, One end of the beam 3-2 is connected to a longitudinal beam 3-1, the other end of the beam 3-2 is connected to another longitudinal beam 3-1, and one end of the longitudinal beam 3-1 is connected to the first The support 4 is connected, the other end of the longitudinal beam 3-1 is connected to the second support 9, a bridge deck is paved on the multiple beams 3-2, and the bridge deck is laid on the bridge deck, The lower end of the sling 2 is connected to the longitudinal beam 3-1, and the upper end of the strut 6 is connected to the longitudinal beam 3-1.

[0106] In this embodiment, the stress situation of the combined self-balancing bridge of the arch bridge and the suspension bridge is that the dead load and the live load of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com