A hollow concrete filled steel tube column with curved inner steel tubes

A technology for hollow steel pipes and concrete columns, which is applied in the direction of columns, pillars, pier columns, etc., can solve the problems of harmful cracks and the difficulty of transferring the heat of hydration of concrete columns to the outside, and achieve the improvement of buckling strength, reduction of fine cracks, and sufficient material performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

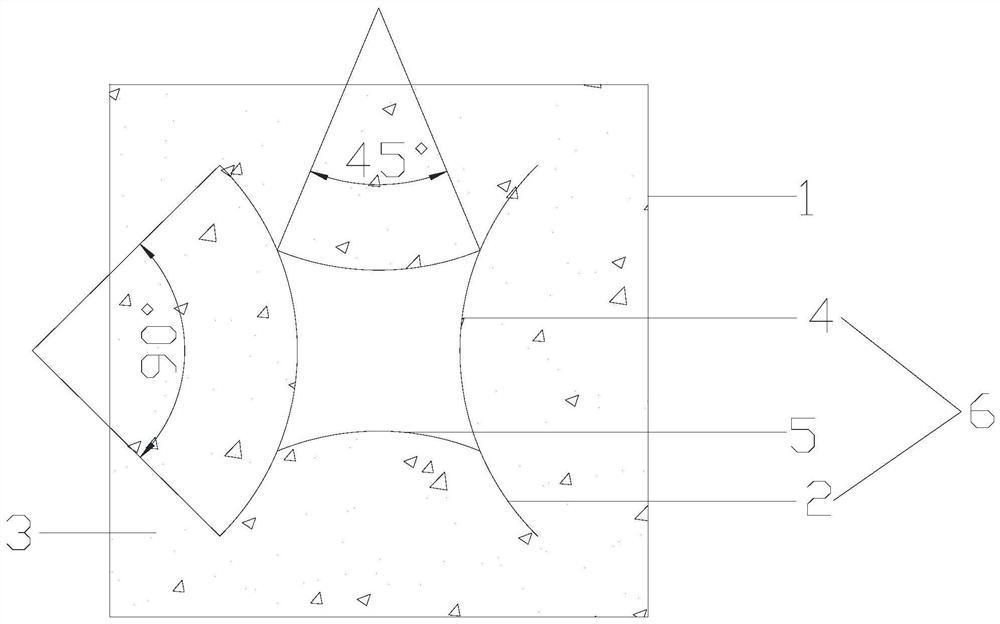

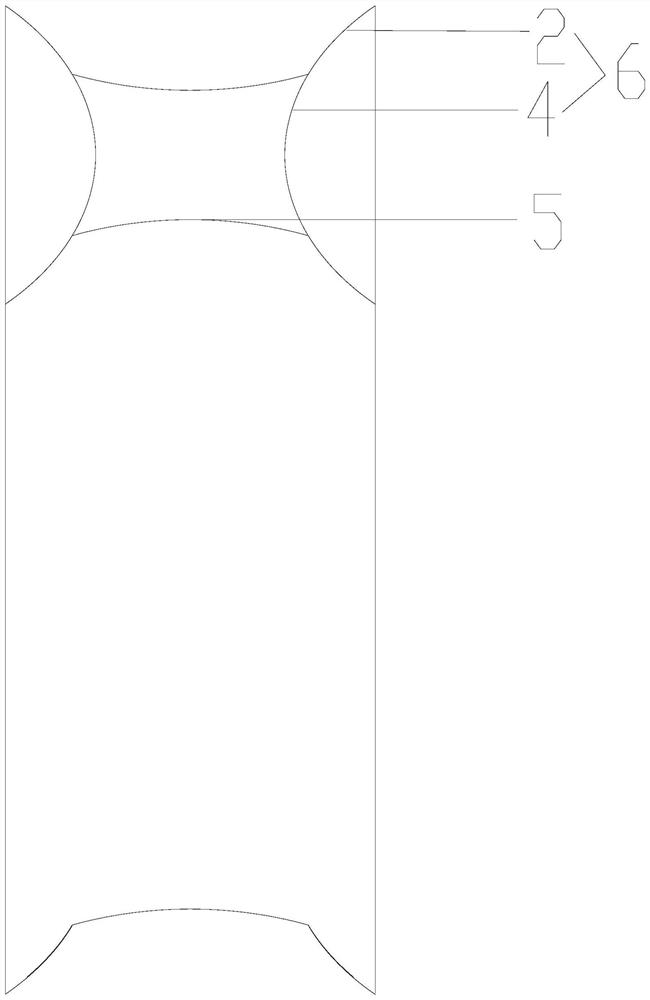

[0026] like figure 1 and figure 2 As shown, this embodiment is a hollow concrete-filled steel tube column with an arc-shaped inner steel tube, which includes an outer steel tube 1 , an inner steel tube and a steel plate extension 2 .

[0027] like figure 1 and figure 2 As shown, the outer steel pipe is a square outer steel pipe, concrete 3 is filled between the outer steel pipe and the inner steel pipe, and the concrete is high-strength concrete. In other embodiments, the outer steel pipe can be circular or other geometric shapes, and the concrete can be self-compacting concrete. Not all of them are listed here.

[0028] like figure 1 and figure 2 As shown, the inner steel pipe includes two first arc-shaped plates 4 and two second arc-shaped plates 5, the two first arc-shaped plates are respectively arranged oppositely, and the two second arc-shaped plates are respectively arranged oppositely, and the second arc-shaped plates are respectively arranged oppositely. The ...

Embodiment 2

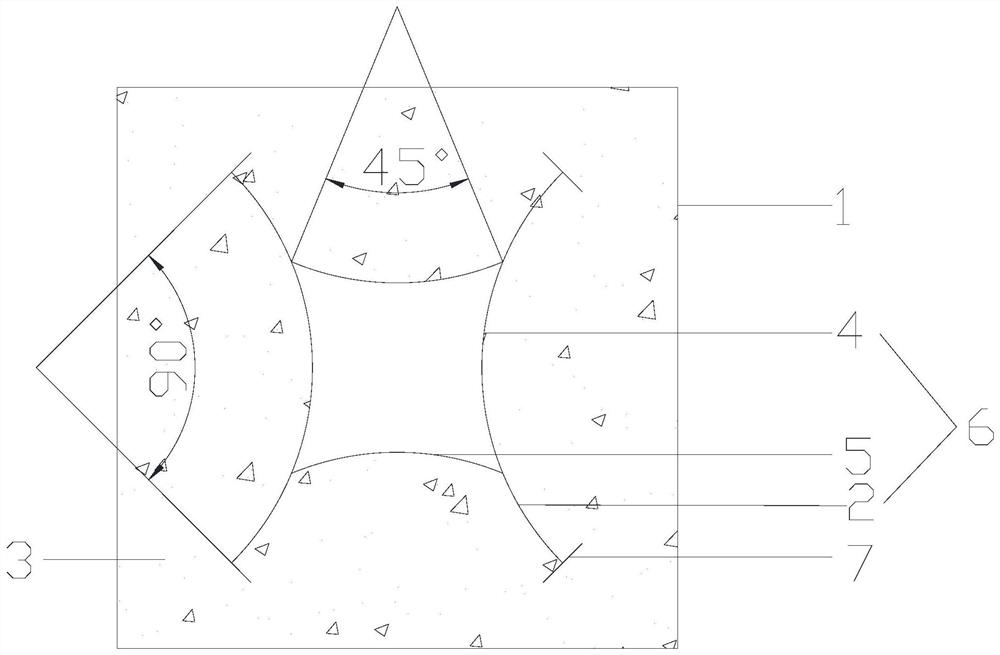

[0031] like image 3 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the above-mentioned hollow concrete-filled steel tube column with arc-shaped inner steel pipes also includes a plurality of straight steel plates 7, and the two ends of the third arc-shaped plates are respectively connected with the plates of the straight steel plates. Surface connection, the tangent at the end of the first curved plate forms an angle with the surface of the straight steel plate, specifically the tangent at the end of the third curved plate is perpendicular to the surface of the straight steel plate, and the straight steel plate along the The longitudinal height of the three-arc-shaped plate is set at the full length, and the relative slip between the inner steel pipe and the concrete is reduced through the straight steel plate. At the same time, the straight steel plate has thermal conductivity, which can transfer the hydration heat generated by the co...

Embodiment 3

[0033] like Figure 5 and Image 6 As shown, the difference between this embodiment and Embodiment 1 is that the steel plate extension is an angle steel, the size of the first arc-shaped plate and the second arc-shaped plate are the same, and the adjacent two first arc-shaped plates and the second arc-shaped plate The ends of the shaped plates are connected to each other, and one side of the angle steel is connected to the junction of two adjacent first and second curved plates, and the cross-sectional central angle of the first and second curved plates is 45° , the angle steel is set along the full length of the longitudinal height of the first arc-shaped plate, and the relative slip between the inner steel pipe and the concrete is reduced through the angle steel, and at the same time, the angle steel has thermal conductivity, which can transfer the hydration heat generated by the concrete to the hollow part, effectively reducing the The tiny cracks produced by the hydration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com