A shaft frequency regulator and engine

A frequency modulator and engine technology, which is applied to shock absorbers, mechanical equipment, springs/shock absorbers, etc., can solve problems such as reducing torsional vibration, and achieve the effects of reducing shaft torsional vibration, simple structure and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

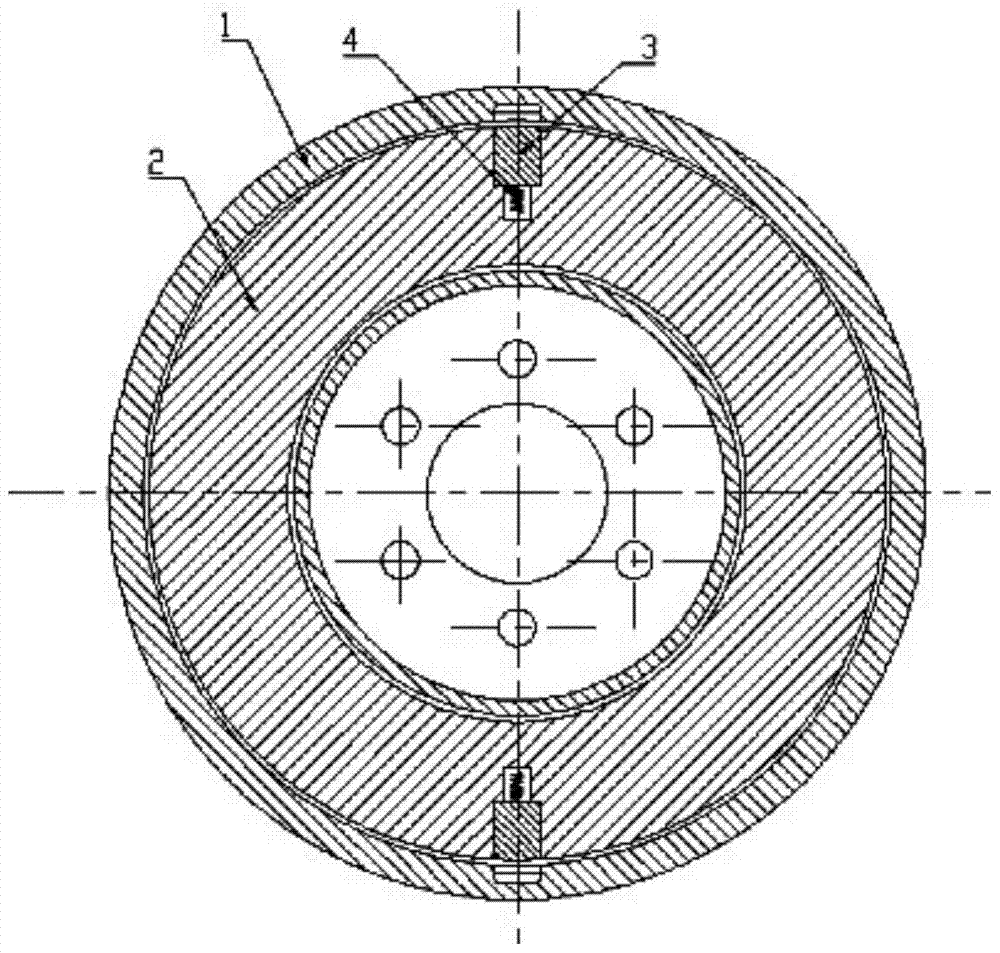

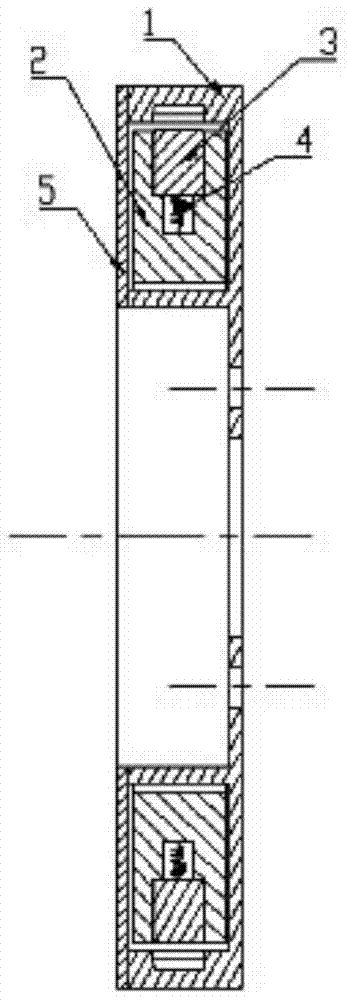

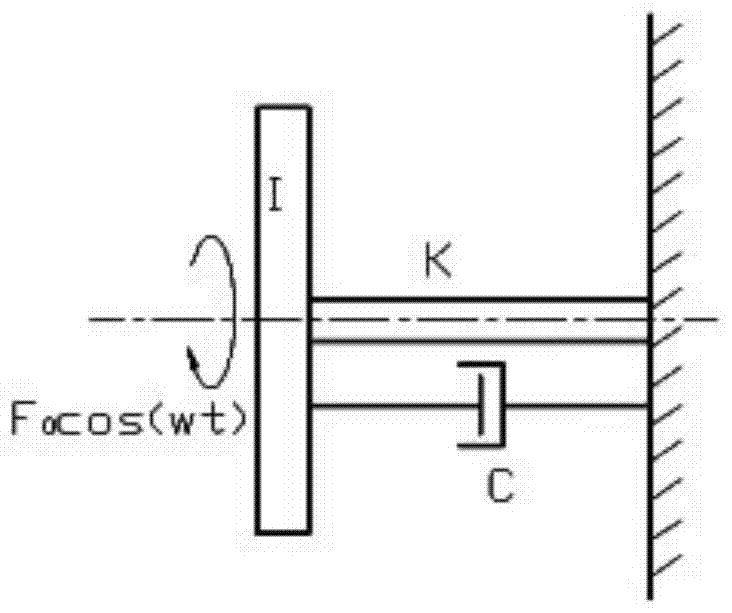

[0029] Such as Figure 1-2 As shown, the shafting frequency modulator provided by this embodiment includes a housing 1, an inertia ring 2, a positioning pin 3, an elastic member 4, and a cover plate 5. The housing 1 is installed at the front end of the crankshaft and is opened on one side of the housing 1. There is an annular mounting groove for accommodating the inertia ring 2; specifically, a mounting hole for mounting the crankshaft is provided at the center of the housing 1. The inertia ring 2 is arranged in the annular installation groove and can slide relatively along the annular installation groove; one end of the positioning pin 3 is connected to the outside of the inertia ring 2 through the elastic member 4, and the inner wall of the annular installation groove is provided with the positioning pin 3 for insertion The cover plate 5 is encapsulated above the annular mounting groove. The shafting frequency modulator can replace the shock absorber to reduce vibration, so ...

Embodiment 2

[0051] The second embodiment also provides an engine, which includes a shafting frequency modulator. The shafting frequency modulator includes a housing 1, an inertia ring 2, a positioning pin 3, an elastic component 4, and a cover plate 5. The housing 1 is installed at the front end of the crankshaft, and an annular installation groove for accommodating the inertia ring 2 is opened on one side of the housing 1 ; Specifically, the center of the housing 1 is provided with a mounting hole for mounting the crankshaft. The inertia ring 2 is set in the annular installation groove and can slide relatively along the annular installation groove; one end of the positioning pin 3 is connected to the outside of the inertia ring 2 through the elastic member 4, and the inner wall of the annular installation groove is provided with the positioning pin 3 for insertion The cover plate 5 is encapsulated above the annular mounting groove. As for other features, please refer to the first embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com