A lignite semi-coke lean oxygen combustion boiler

A low-oxygen combustion and lignite semi-coke technology, applied in the boiler field, can solve problems such as low combustion intensity, excessive pollutant discharge, and narrow load adjustment range, and achieve the effects of increasing slag filling rate, increasing conversion rate, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

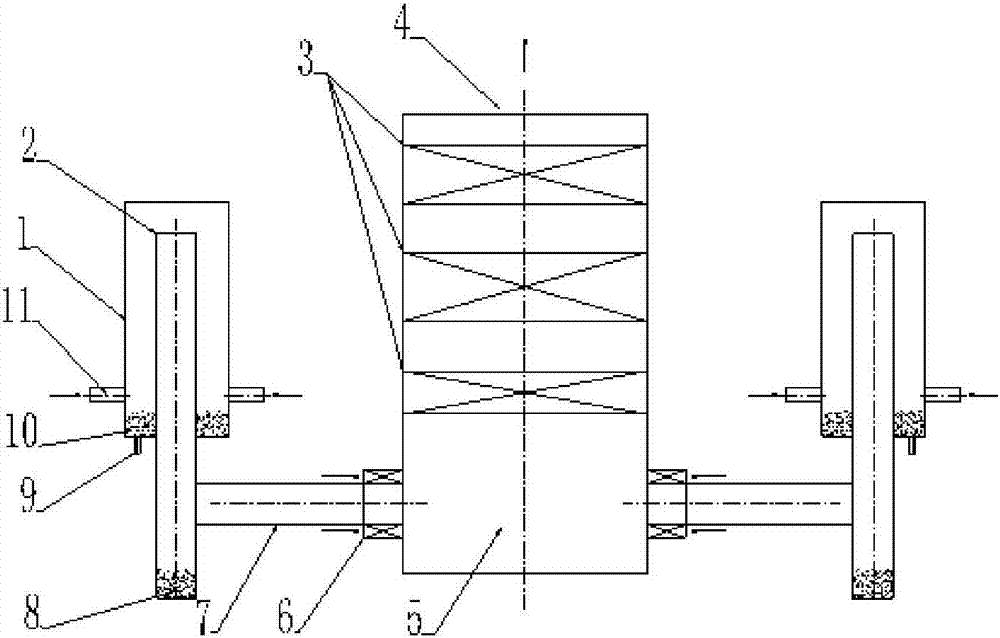

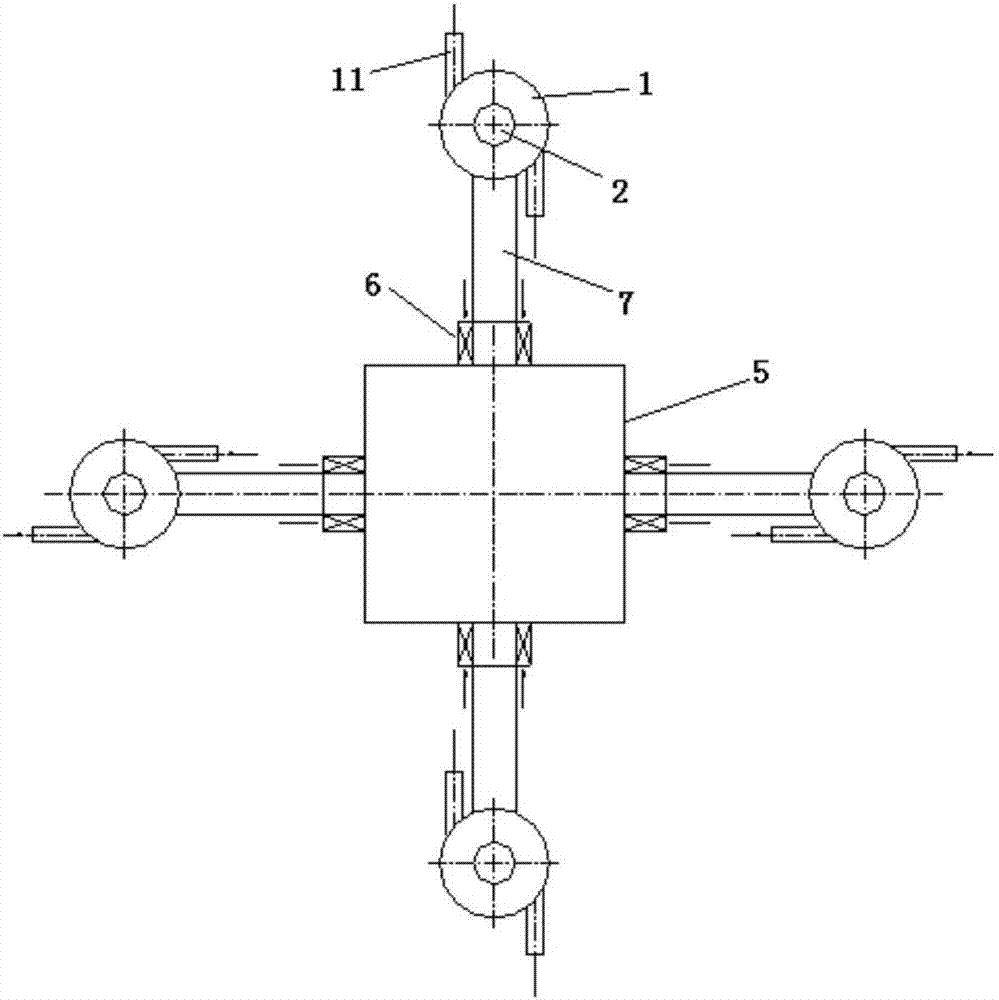

[0034] see figure 1 As shown, a lignite semi-coke lean-oxygen combustion boiler of the present invention includes several cyclone oxygen-lean combustion devices and a boiler body, both of which are arranged in a satellite shape.

[0035] The bottom of the boiler body is the secondary combustion chamber 5, the upper part of the secondary combustion chamber 5 is the boiler heating surface 3 arranged in a tower type, and the top of the boiler heating surface 3 is provided with a smoke exhaust port 4.

[0036] The cyclone lean oxygen combustion device includes a cyclone 1 , a central tube 2 , a flue gas duct 7 and a secondary air cyclone 6 . The lower side wall of the cyclone 1 is provided with a primary tuyere 11 which is slightly inclined downward; each side wall of the cyclone 1 is provided with two primary tuyeres 11 for forming a cyclone in the cyclone 1 . The center of the bottom of the cyclone 1 has a through hole, and the central tube 2 extends into the interior of the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com