Locatable bilinear cumulative blasting device in smooth blasting hole and blasting method

A bilinear and energy-gathering technology, applied in blasting and other directions, can solve problems such as increased cost, structural limitations, and collapsed holes in broken rock, and achieves the effect of reducing clamping effect, saving costs, and reducing impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

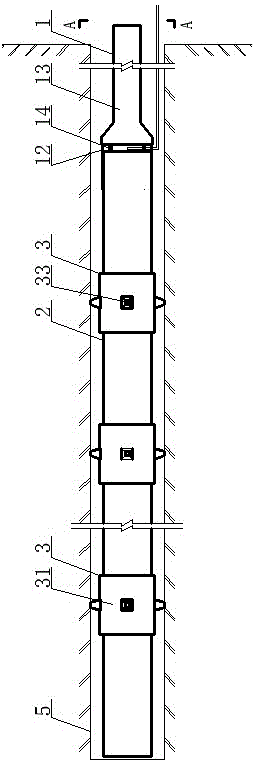

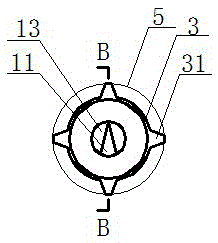

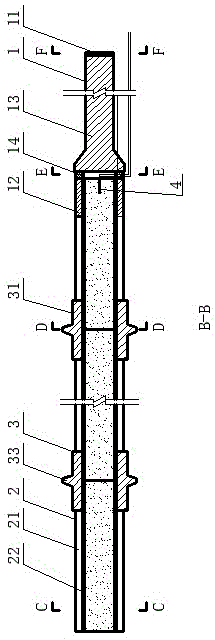

[0039] Attached below Figure 1-8 And embodiment further illustrate the present invention.

[0040] In the accompanying drawings, a bilinear energy-concentrating blasting device that can be positioned in a light blasting hole includes a bilinear energy-concentrating tube 2, a center positioning device 3 in the hole, an electric detonator 4 that is permitted for coal mines, and a bilinear energy-concentrating blasting device filled in the bilinear The coal mine allowable explosives in the type shaped charge tube 2; the double-line type shaped charge tube 2 is provided with a multi-section tube body 22, and the outer wall of the tube body 22 is symmetrically provided with a V-shaped double-line type energy-gathering groove 21, and is formed by a hole The inner center positioning device 3 is used as a connecting part to connect the end to the end; when the bilinear energy-concentrating blasting device is installed in the optical blasting hole 5, the coal mine allowable electric d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com