Rotation machinery torsional vibration signal collection analysis method

A technology of torsional vibration and signal acquisition, which is applied in the direction of using electrical devices, measuring devices, instruments, etc., can solve the problems of shaft fatigue damage, many factors affecting test results, and complicated torsional vibration testing, so as to reduce errors, reduce missing teeth, Effects of Improving Counting Precision and Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

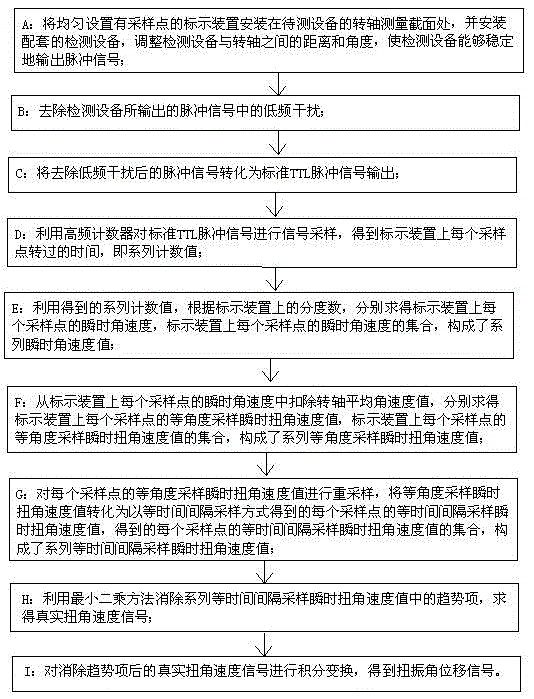

[0047] Such as figure 1 As shown, the rotating machinery torsional vibration signal acquisition and analysis method of the present invention comprises the following steps in turn:

[0048]A: Install the marking device evenly arranged with sampling points at the measurement section of the rotating shaft of the equipment to be tested, and install the supporting testing equipment, adjust the distance and angle between the testing equipment and the rotating shaft, so that the testing equipment can output pulse signals stably .

[0049] In the present invention, the marking device provided with sampling points adopts a uniformly graduated gear plate, and the matching detection equipment adopts eddy current sensors or magnetoresistive sensors, which can convert detected pulse signals into electrical signals for output.

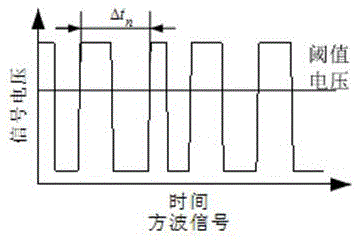

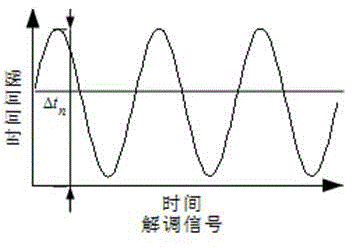

[0050] When there is no torsional vibration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com