Fiber grating sensor insert for mould pressing product detection and manufacturing method thereof

A technology of optical fiber grating and molded products, which is applied in the direction of using optical devices, instruments, and measuring heat. It can solve problems such as damage and fiber softness, and achieve the effects of reducing installation costs and improving survival rate and operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

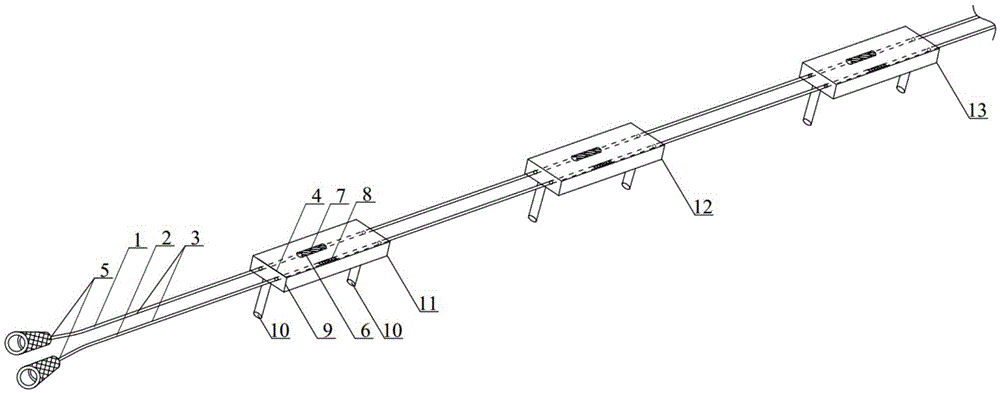

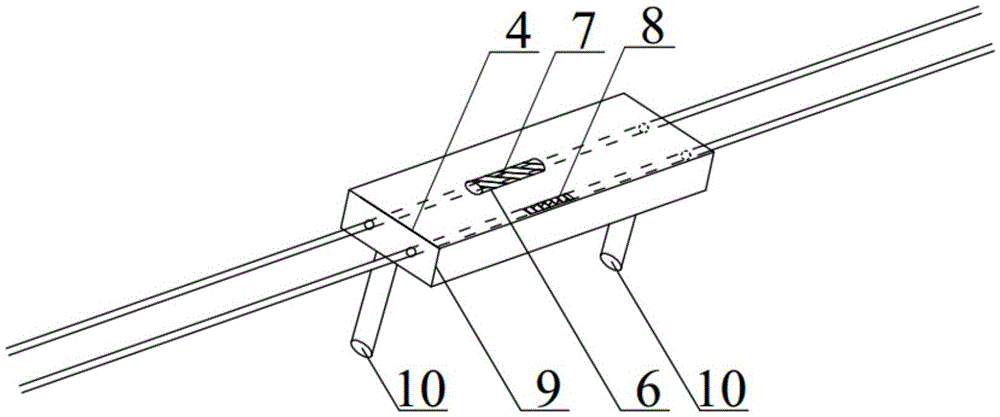

[0058] An on-line detection fiber grating sensor insert for a filter plate of a filter press formed by a molding process

[0059] like figure 1 As shown in , the insert consists of a fiber grating for temperature measurement and a fiber grating for strain measurement, and six grating units are engraved on each fiber (schematic figure 1 Only three are drawn in the figure), each grating unit is an independent sensor, and the central wavelengths of the grating units are 1512nm, 1516nm, 1520nm, 1524nm, 1528nm, 1532nm. The material of the optical fiber protective layer and the grating encapsulator is the same as that of the filter plate of the filter press, all of which are polypropylene. The thickness of the grating protective layer polypropylene is 1mm. The grating unit is protected by grating wrappers. Each optical fiber has six grating wrappers. A hard and temperature-resistant fiber optic connector embedded joint is installed at one end of each optical fiber.

[0060] The sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com