Formation method of TEM sample

A technology for transmission electron microscope samples and samples, which is applied in the field of semiconductor manufacturing, can solve the problems of destroying the complete wafer, the accuracy cannot meet the detection requirements, etc., and achieves the effect of accurate size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

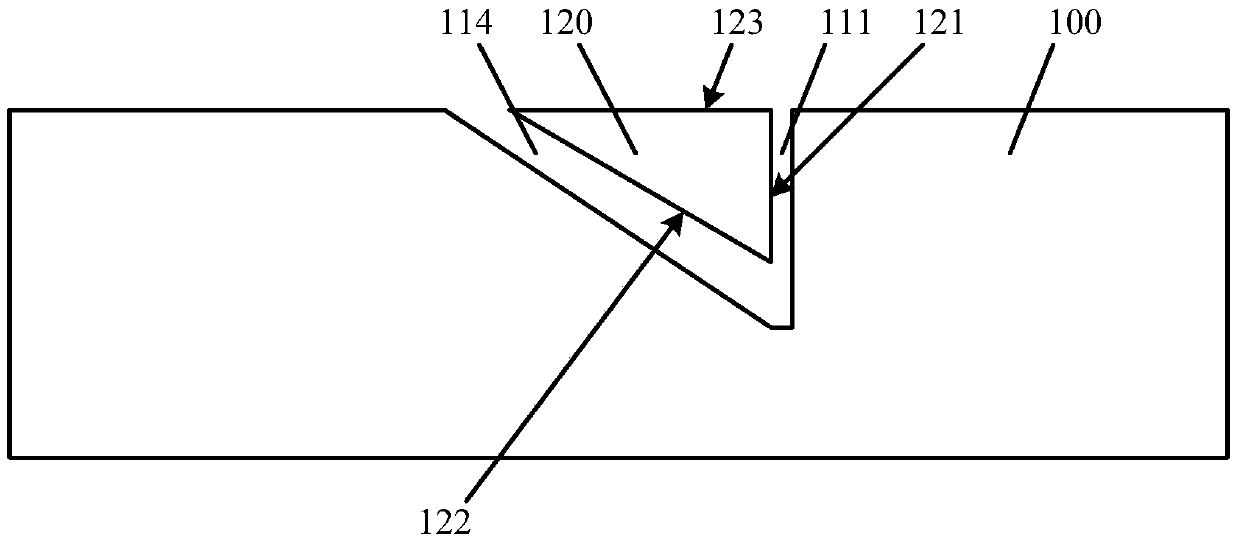

[0028] As mentioned in the background art, the existing method for forming samples will completely destroy the complete wafer, and the precision of the formed sample size is poor.

[0029] After research, it is found that in the existing sample preparation process, in order to obtain the primary sample, the wafer needs to be diced, and only part of the wafer including the target area in the wafer is reserved. Therefore, in order to obtain the primary sample, the complete If the wafer is completely destroyed, the wafer can no longer be used for other processes or inspections except for transmission electron microscope inspection, so that the utilization rate of the wafer is low, and the cost of the transmission electron microscope inspection is too high .

[0030] Moreover, in the existing sample preparation process, processes such as forming the first cutting mark, dicing the wafer, forming the grinding mark, grinding the primary sample, and finely grinding the surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com