Improved device for pressing diamond and aligning diamond with base

A centering device and diamond technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as looseness, disappearance of the indenter, and reduction of the pressing force, and achieve the effect of avoiding bump damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

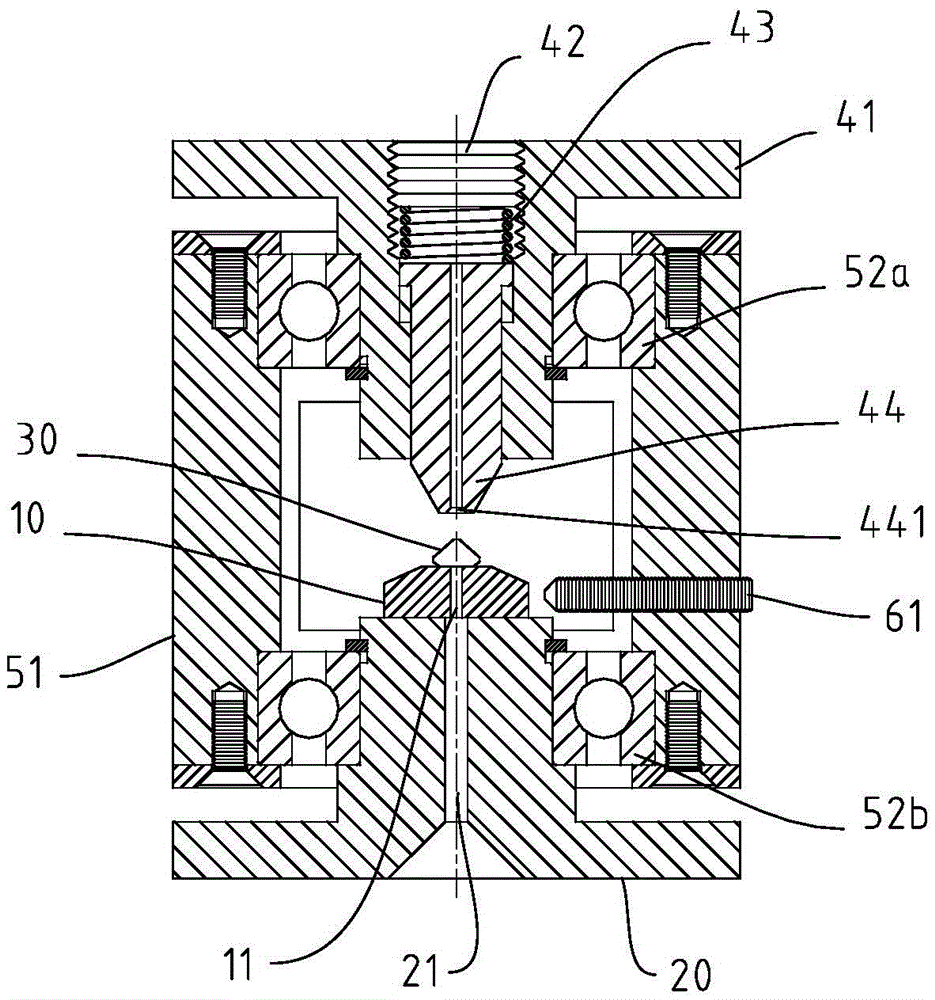

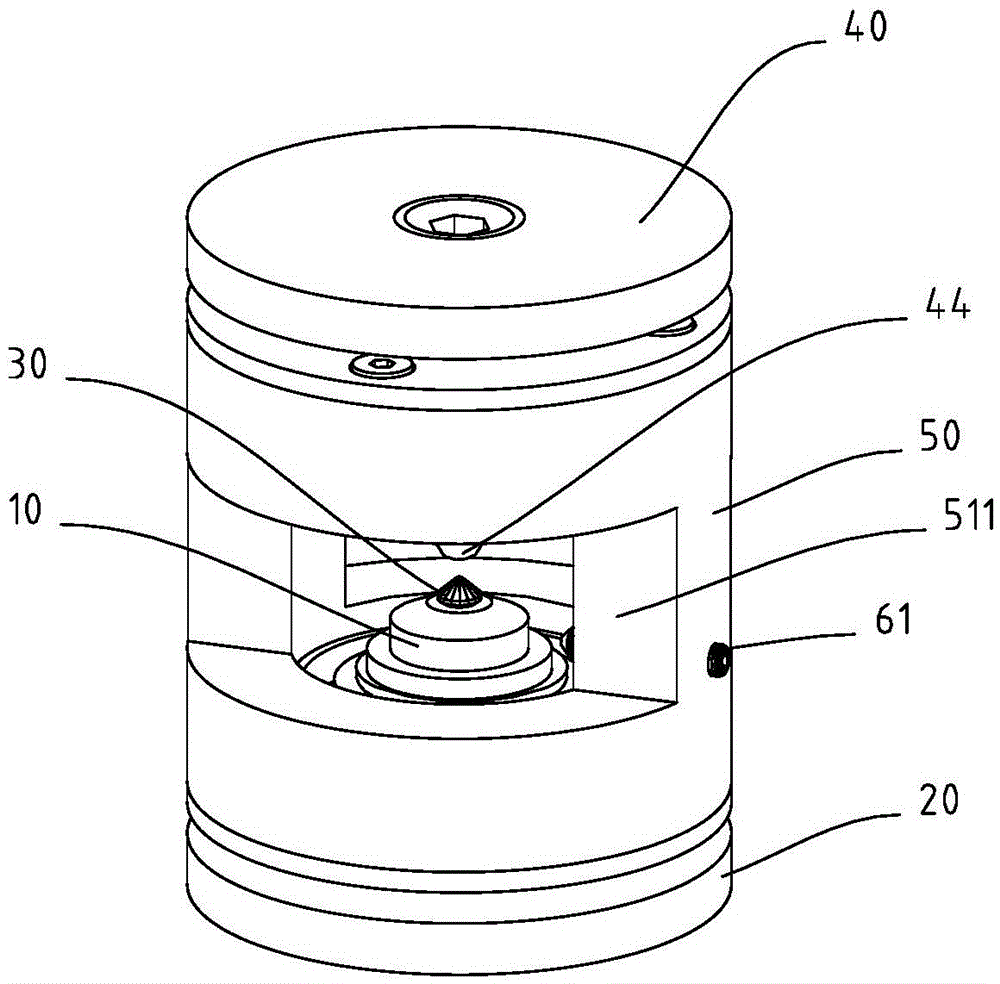

[0026] The improved diamond and base pressing and centering device of the present invention includes a base 20 for placing the base 10 and a pressing mechanism 40 that applies pressure to the working surface of the diamond 30. The base 20 is provided with a center line and An observation hole 21 parallel to the center line of the through hole 11 on the base 10, the center line of the observation hole 21 coincides with the pressing direction of the pressing mechanism 40, and the base 20 is connected with a main body for supporting the pressing mechanism 40 The supporting structure 50, the main supporting structure is provided with an adjustment mechanism for adjusting the relative position of the diamond 30 and the base 10, and the supporting structure 50 of the main body can be carried out relative to the base 20 and the pressing mechanism 40 around the center line of the observation hole 21. turn. In the present invention, there may be relative movement between the main body ...

Embodiment 2

[0033] The pressing and centering device also includes a gluing mechanism that bonds the diamond 30 and the base 10 together, the gluing mechanism includes a driving device that drives the base 20 to rotate, and an injection device for gluing, the injection The glue outlet of the device faces the pressing surface between the diamond and the base. The epoxy resin glue used for bonding and fixing the diamond 30 and the base 10 can be injected through an injection device, which is similar to a syringe, absorbs the glue prepared in proportion, slowly squeezes the piston, and the glue will flow out evenly. When applying glue, the diamond 30 and the base 10 should be in a relatively fixed position, and the motor drives the base 20 to rotate slowly, and the injection device with a relatively fixed position will evenly smear the glue around the pressing surface of the diamond 30 and the base 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com