Device for measuring Seebeck coefficient and method of device

A measurement method and coefficient technology, applied in the direction of measuring device, measuring heat, using electric device, etc., can solve the problems of high measurement accuracy of Seebeck coefficient and high requirements for measuring sample shape, so as to improve temperature measurement accuracy, improve measurement accuracy, The effect of overcoming shape constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

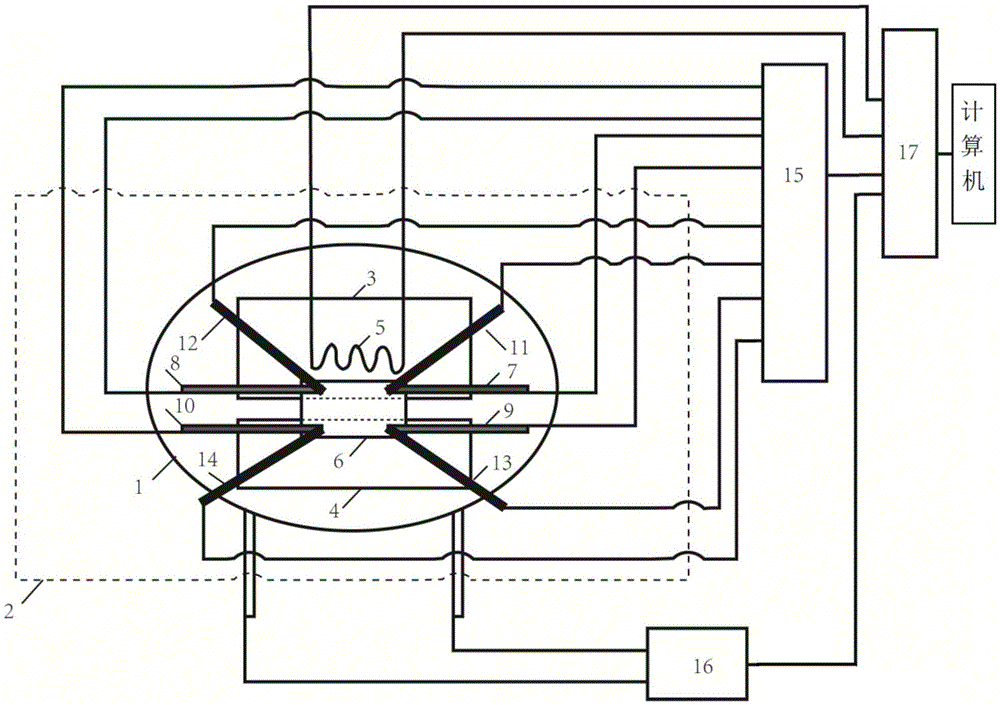

[0051] Such as figure 1 As shown, the device for measuring the Seebeck coefficient includes a main heater 1, an auxiliary heater 5, a first insulating heat conductor 3, a second insulating heat conductor 4, a first main probe 11, a first auxiliary probe 12, a second main probe Probe 13, second auxiliary probe 14, first main thermocouple 7, first auxiliary thermocouple 8, second main thermocouple 9 and second auxiliary thermocouple 10; wherein,

[0052] The first insulated heat conductor 3 and the second insulated heat conductor 4 are all located on the main heater 1, and the first insulated heat conductor 3 and the second insulated heat conductor 4 are not in direct contact; the first insulated heat conductor 3 and the second insulated heat conductor The thermal conductors 4 are all used to place the sample to be measured; one end of the sample to be measured is in contact with the first insulating thermal conductor 3, and the other end is in contact with the second insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com