Method for performing weld-joint ultrasonic detection through frequency-phase compound coding excitation signal

A technology of phase encoding signal and composite encoding, which is applied in the field of welding structure quality inspection, and can solve problems such as inability to obtain inspection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific Embodiments 1. The method for ultrasonic detection of welding seams using frequency-phase composite coded excitation signals described in this embodiment is carried out according to the following steps:

[0020] 1. Edit frequency-phase composite coded signal;

[0021] 2. Import the frequency-phase composite encoded signal obtained in step 1 into the signal generator;

[0022] 3. The signal generator sends out frequency-phase composite coded pulse excitation signal;

[0023] 4. Add the pulse excitation signal obtained in step 3 to the ultrasonic detection probe after being amplified by the power amplifier;

[0024] 5. The ultrasonic detection probe converts the amplified electrical signal obtained in step 4 into an acoustic signal and adds it to the tested piece;

[0025] 6. The acoustic signal obtained in step 5 propagates in the specimen and is reflected when it meets the interface;

[0026] 7. The ultrasonic detection probe receives the reflected sound sig...

specific Embodiment approach 2

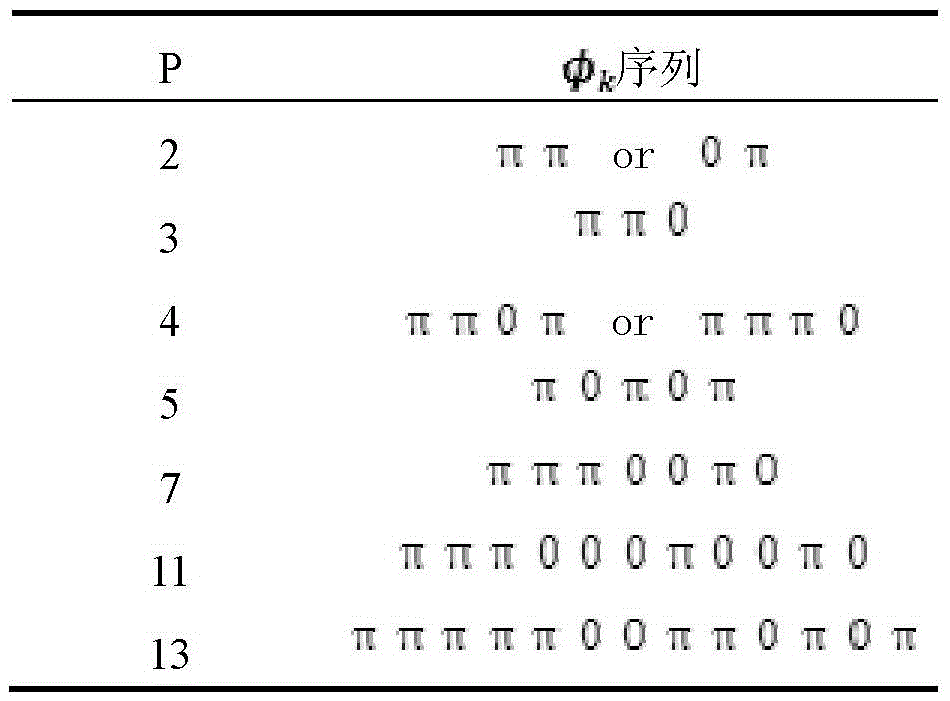

[0033] Specific embodiment 2. This embodiment is a further description of the method for ultrasonic detection of weld seams using frequency-phase composite encoding excitation signals described in specific embodiment 1. The frequency-phase composite encoding signals described in step 1 use phase encoding The signal is composited with a frequency-encoded signal.

specific Embodiment approach 3

[0034] Specific Embodiment 3. This embodiment is a further description of the method for ultrasonic detection of welds using frequency-phase composite coded excitation signals described in specific embodiment 1 or 2. The frequency-phase composite coded signal described in step 1, which The composite form is to change the original single-carrier frequency signal into a frequency-coded signal in each code of the phase-coded signal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com