Analysis system and method of microbubble behavior in ultrasonic field based on superhigh speed photograph technology

An ultra-high-speed, ultrasonic field technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, material analysis, ultrasonic/sonic waves/infrasonic wave diagnosis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

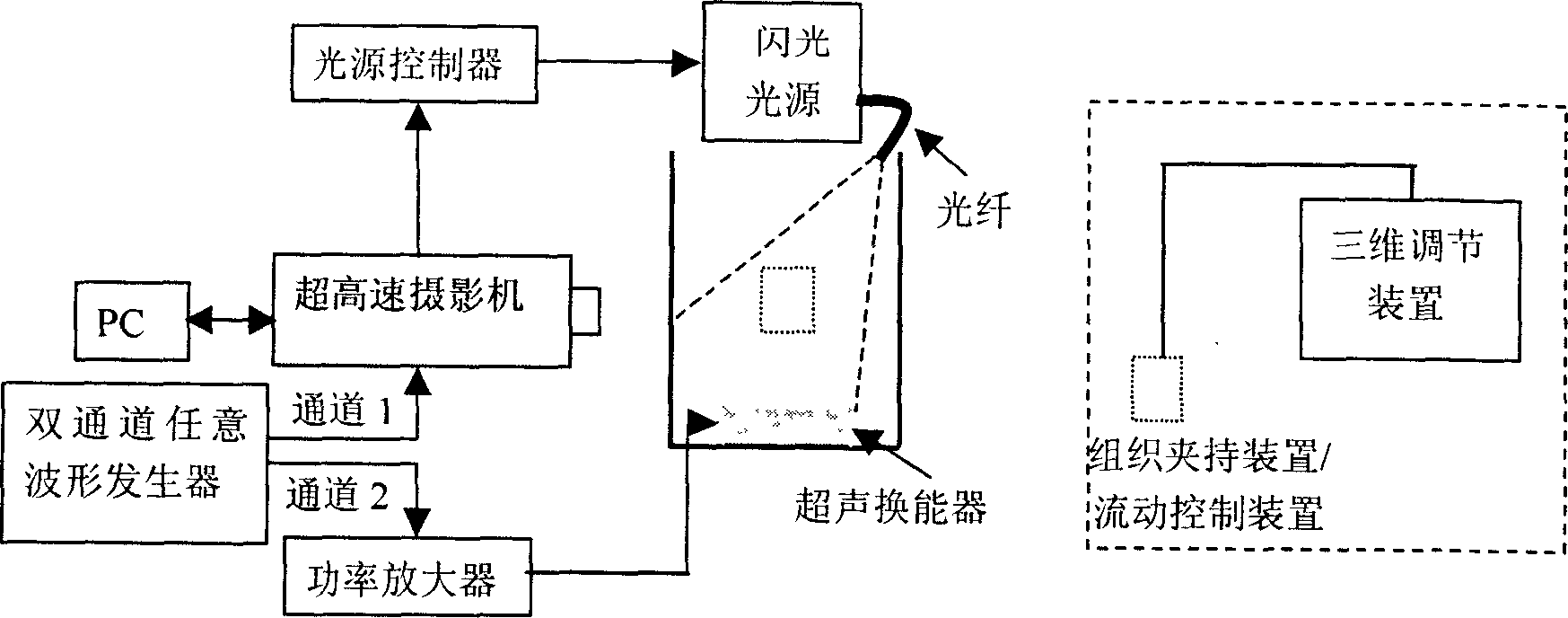

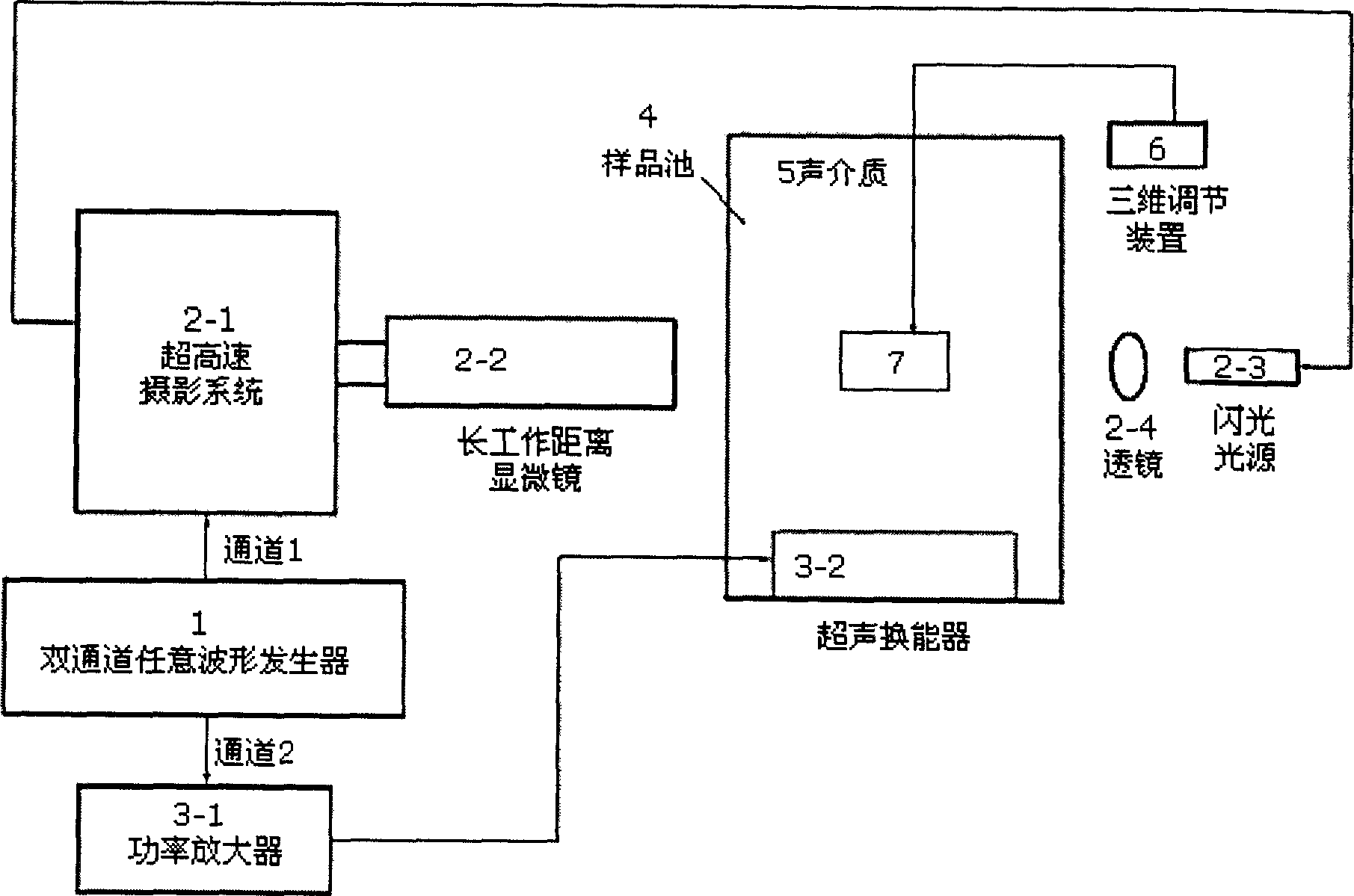

[0116] Embodiment 1: Observing the behavior of microbubble groups in the ultrasonic field with an ultra-high-speed photography system

[0117] 1) Reference figure 1 , adjust the position of the tank so that the region of interest is within the field of view of the high-speed camera.

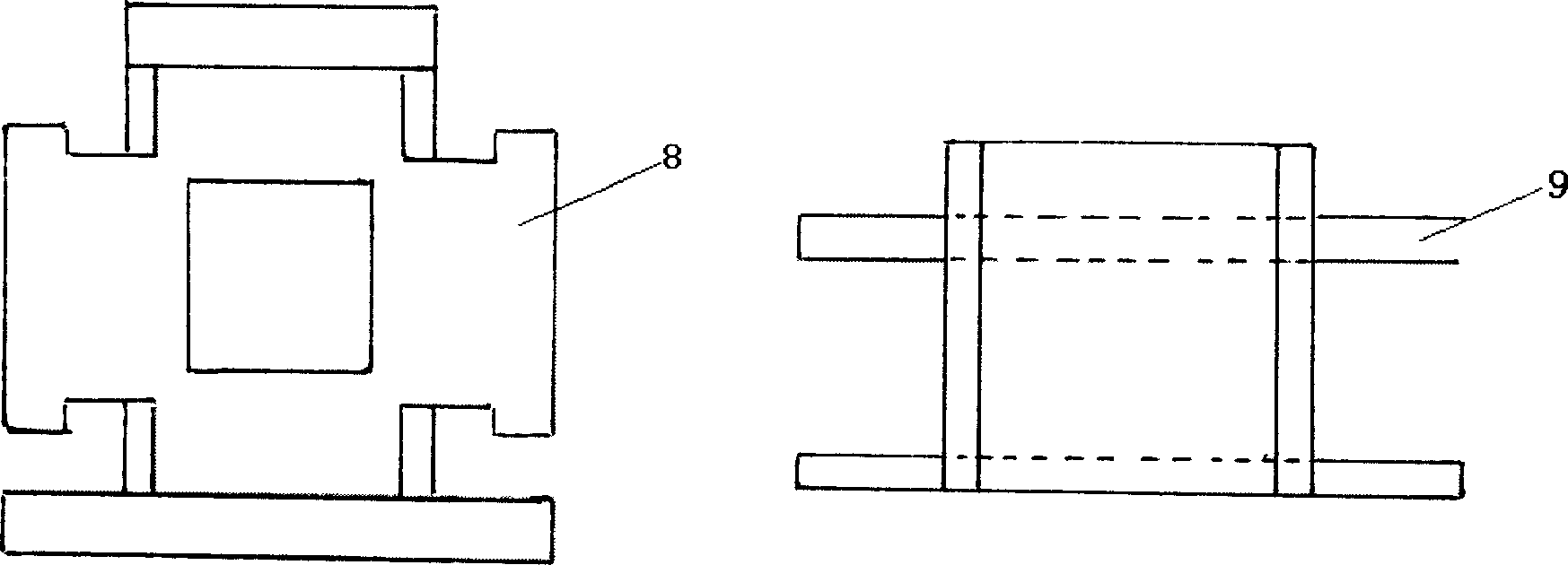

[0118] 2) Use non-degassed water as the acoustic medium, and when observing the coated microbubbles, it is necessary to inject the coated microbubbles (such as SonoVision) into the water. To analyze the behavior of microbubble groups near tissues in the ultrasonic field, it is also necessary to fix the biological tissue in the clamping device (refer to image 3 ), and fix the clamping device on the three-dimensional adjustment device to adjust its position in the sound field. To analyze the behavior of the microbubble group in the microtube in the ultrasonic field, it is necessary to inject a uniform solution containing the coated microbubble into the fiber tube through the flow control device....

Embodiment 2

[0125] Embodiment 2: Combining frequency modulation and amplitude modulation to control the generation and rupture of microbubble groups

[0126] The ultrasound transducer uses a high-intensity focused ultrasound transducer. Change figure 1 The output signal of channel 2 of the dual-channel arbitrary waveform generator is changed from a single-frequency sinusoidal signal to a sinusoidal signal combined with frequency modulation and amplitude modulation, such as Figure 7 shown. In the signal sequence in the figure, a high-amplitude single-frequency sinusoidal signal is first used to generate cavitation microbubbles in the target medium only in the focal region of the high-intensity focused ultrasound field, and then a low-amplitude frequency-modulated sinusoidal signal is used to make the cavitation microbubbles rupture, so as to achieve the purpose of controlling cavitation. Specific steps are as follows:

[0127] 1) Using the method in Example 1, determine the power of t...

Embodiment 3

[0130] Example 3: Single microbubble strain estimation based on microscopic high-speed photography image sequences

[0131] Adopt the method that embodiment 1 introduces, obtain microscopic high-speed photography image sequence, take out wherein two frames (refer to Figure 8 ) to preprocess it, including histogram equalization and edge extraction, we can get Figure 9 The results shown. right Figure 9 The results in ellipse fit to obtain the corresponding centroid position, and use the correlation feedback algorithm based on the genetic algorithm to process the centroid displacement of the microbubble, and the corresponding optical flow diagram of the microbubble movement ( Figure 10 (b)) and strain estimation grayscale image ( Figure 10 (c)).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com