Method and priority system for inventory management in semiconductor manufacturing

A semiconductor and inventory technology, applied in semiconductor/solid-state device manufacturing, general control system, control/regulation system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

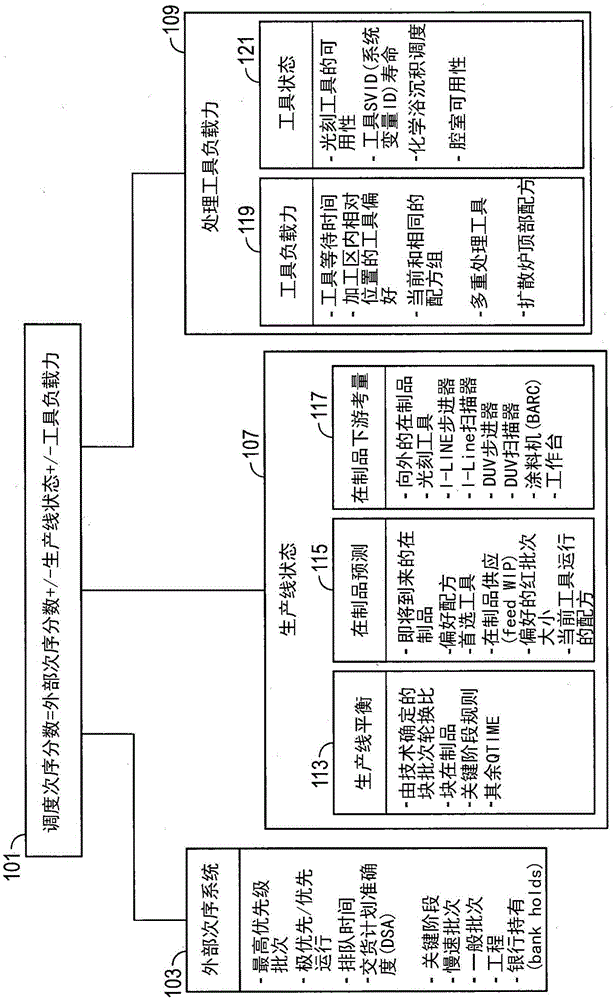

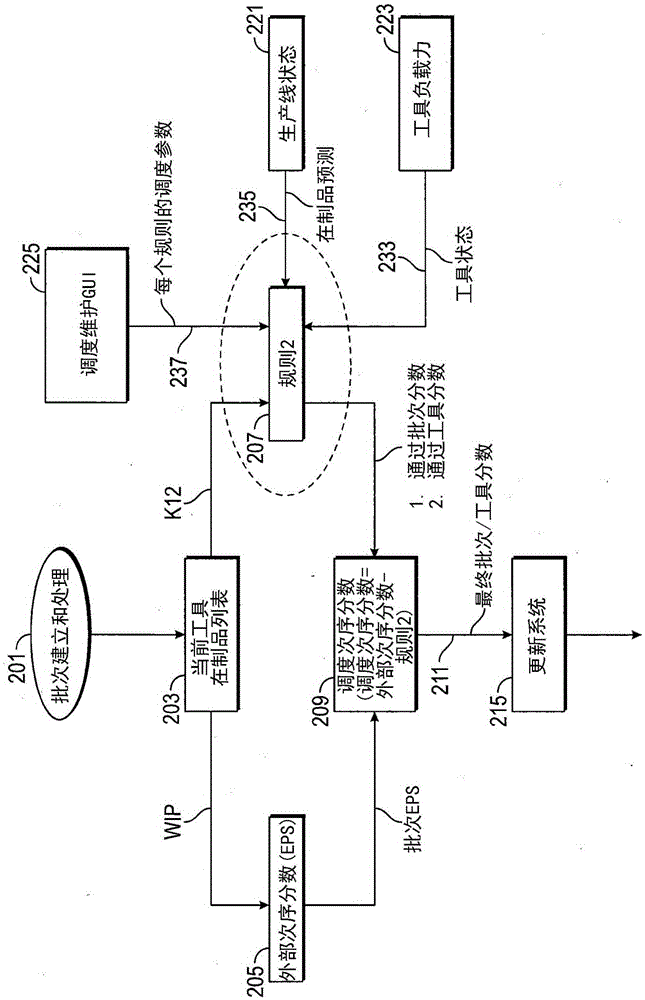

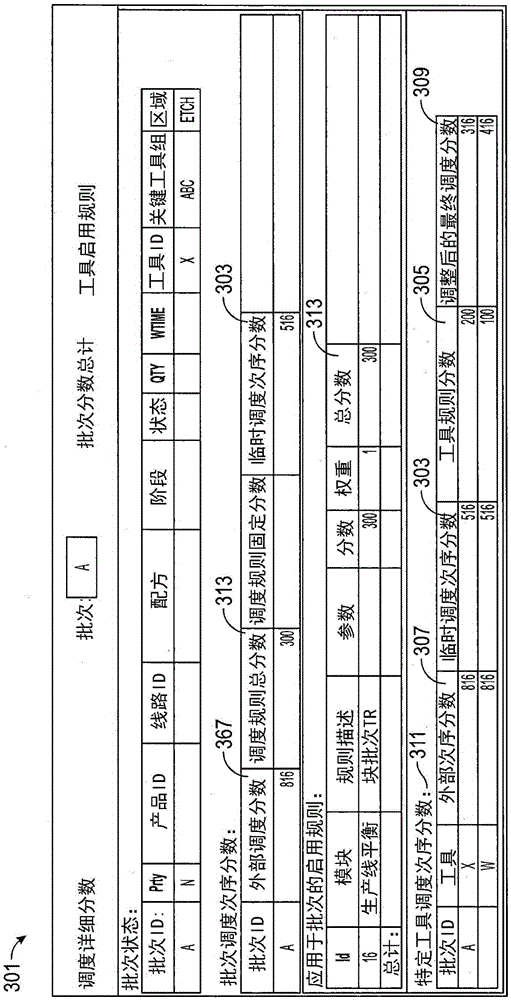

[0010] An inventory management system is provided for use in a production environment, such as a semiconductor fab, commonly referred to as a "fab." In semiconductor manufacturing, integrated circuits and other semiconductor devices are formed on substrates, such as silicon substrates, other suitable semiconductors or substrates, or referred to as "die". These bases are usually grouped into lots. The term "lot" (or batch) is what is generally known as a group of substrates that are processed together through a processing facility. Each batch therefore contains several substrates that are processed together as a group. Through a series of processes, each batch of substrates is processed through a large number of handling operations, testing operations, and measuring operations, thereby manufacturing semiconductor devices. By "processing" a batch of substrates, performing an operation on each substrate within the batch, and depending on the equipment or tool that performs the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com