Method and system for monitoring leak rate of HDP chamber

A chamber and leak rate technology, used in electrical components, circuits, semiconductor/solid-state device testing/measurement, etc., can solve problems such as inability to find problems in a timely manner, inability to monitor in real time, and the impact of hole filling capabilities. The effect of automatic leak rate monitoring and product risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

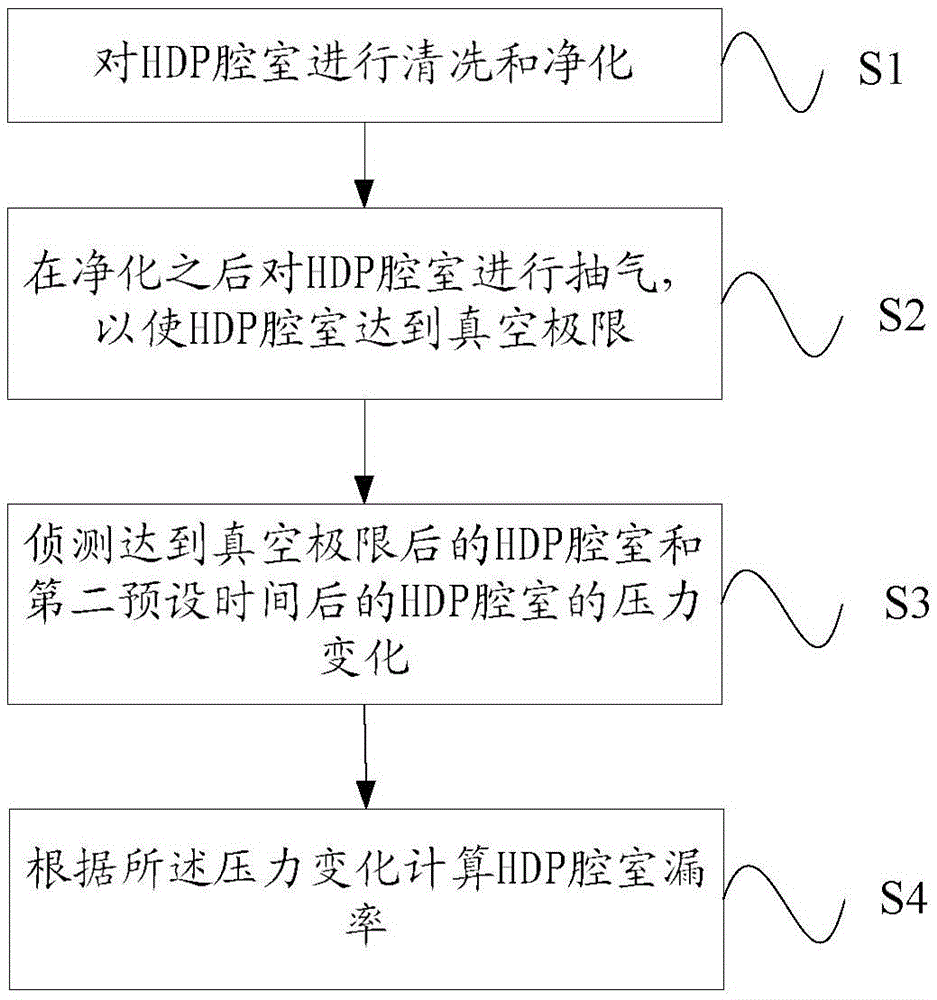

[0038] like figure 2 and 3 As shown, the present invention provides a method for monitoring the leak rate of a HDP chamber, comprising:

[0039] Step S1, cleaning and purifying the HDP chamber;

[0040] Step S2, evacuating the HDP chamber after purification, so that the HDP chamber reaches the vacuum limit;

[0041] Step S3, detecting the pressure change of the HDP chamber after reaching the vacuum limit and the HDP chamber after a second preset time;

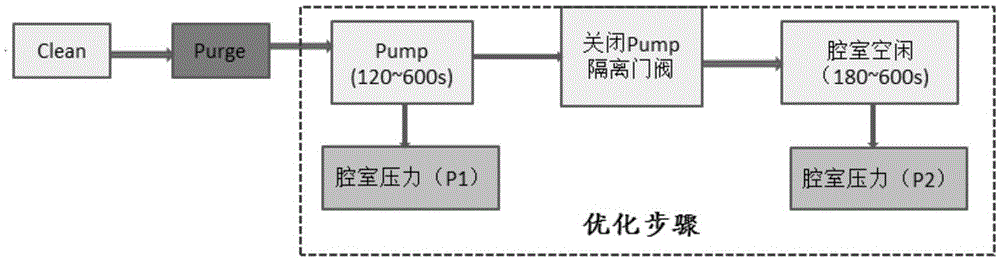

[0042] Step S4, calculating the leakage rate of the HDP chamber according to the pressure change. This embodiment optimizes the purging (purge) and pump (pumping) process after cleaning (clean), and after purging, pumps for a long time and seals the chamber for a long time, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com