Storage battery electrode plate formation frame

A technology for forming racks and batteries, applied in lead-acid batteries, lead-acid battery construction, sustainable manufacturing/processing, etc., can solve problems such as increased production costs and large quantities, and achieve lower production costs, reduce labor intensity, and improve labor efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

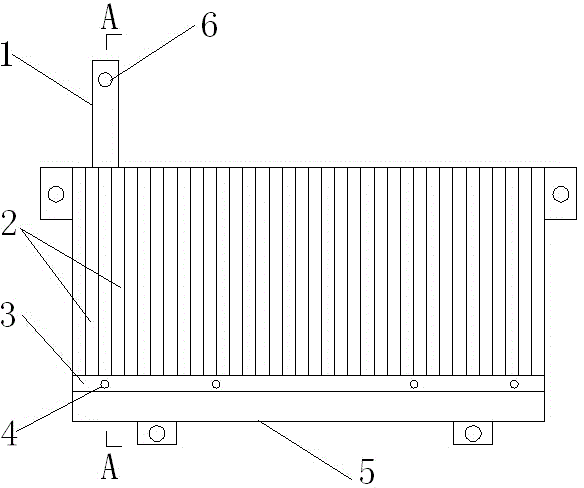

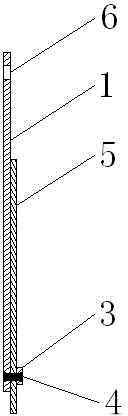

[0012] The present invention will be further described in detail in conjunction with the accompanying drawings. A storage battery pole plate forming frame includes a forming plate comb 5, a longitudinal groove 2 is provided on one side of the forming plate comb 5, and a vertical groove 2 is provided at the lower end of the longitudinal groove 2. Conductive electrode bar 3, the conductive electrode bar 3 is electrically connected with the lower end of the lead bar 1 that is located at the other side of the forming board comb 5.

[0013] In order to facilitate processing and use ready-made materials, and have good electrical conductivity, the conductive electrode bar 3 is riveted together with the lead bar 1 through the lead rivet 4 . Lead rivets are rivets made of lead.

[0014] In order to facilitate the processing and use of ready-made materials, and have good electrical conductivity, the lead strip 1 is connected with the formed board comb 5 through lead rivets.

[0015] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com