Precompressor, winder and method for operating the winder

A technology of pre-compressor and winding machine, which is applied in the direction of winding mechanism, textile and paper making, fiber processing, etc., which can solve the problems of low winding speed and loss of productivity, and achieve the reduction of bubble formation, low fluff, and roll uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

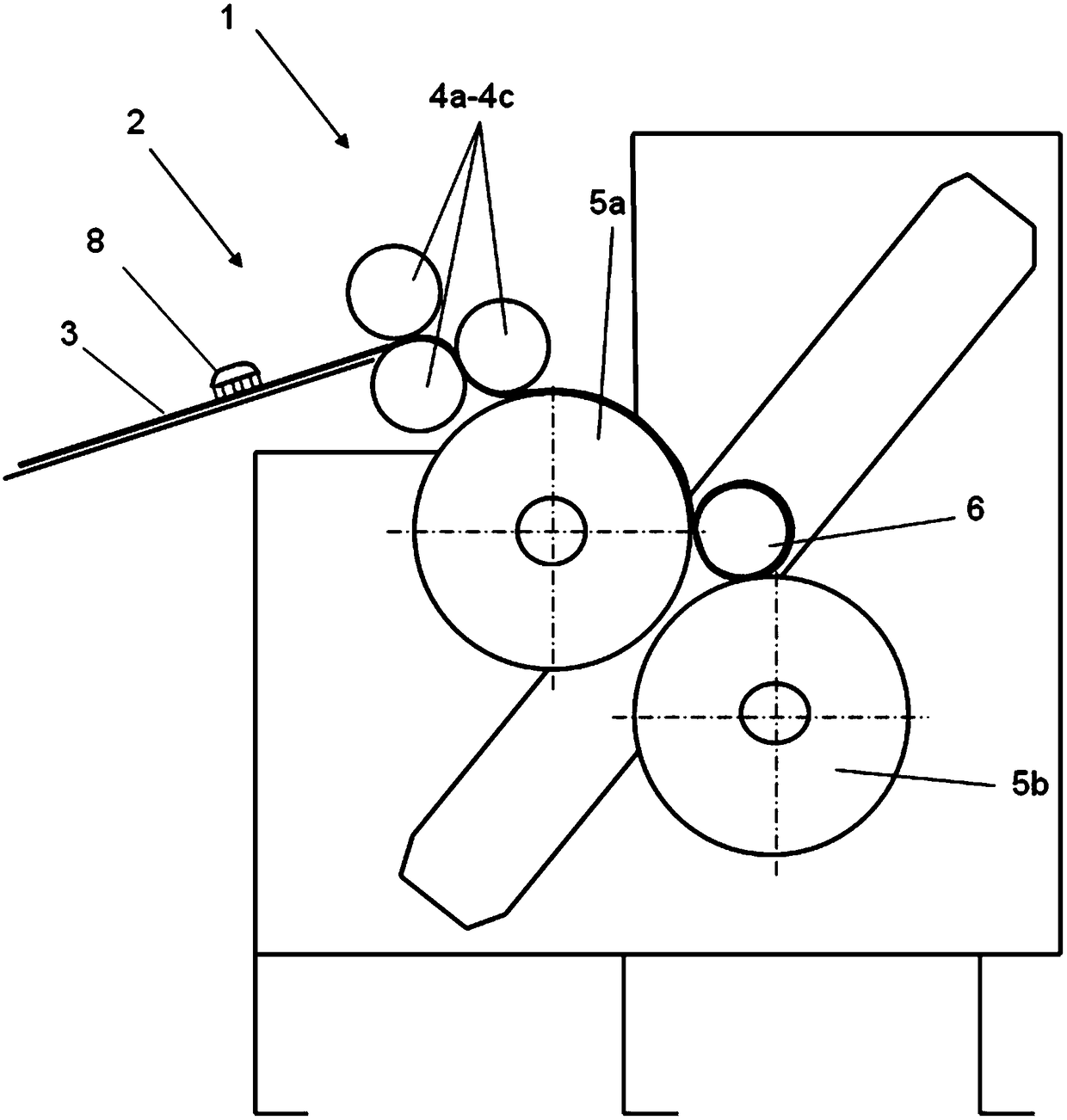

[0052] exist figure 1 A winder 1 is shown in , as it is used, for example, in combing preparations in the textile industry. A plurality of fiber strips 3 , which may be made of natural or synthetic fibers, are fed through the cans of the winder 1 and compared in a drafting device not shown. The fiber strip 3 is guided through the feed area 2 to a plurality of pressing rollers 4a-4c, which guide the fiber strip 3 between the two winding rollers 5a, 5b and the winding sleeve 6 for producing the lap. in the pull-in area between them. A precompressor 8 , which contrast-adjusts the fiber strip 3 , is arranged in or on the feed region 2 . The winding pressure can be produced by two laterally arranged cylinders, not shown, which draw or press the winding sleeve 6 onto the winding rollers 5a, 5b.

[0053] In addition to the embodiment with two winding rollers 5 a , 5 b , winders are known in which the lap is formed inside a revolving belt or via a belt with winding rollers. Howeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com