Combined tool for spraying paint protection for main wheel of plane

A technology of main engine wheel and aircraft, applied in the direction of injection device, etc., can solve the problems of high work intensity, long time-consuming paint protection, difficult to guarantee maintenance cycle and maintenance quality, etc., and achieve the effect of easy removal and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

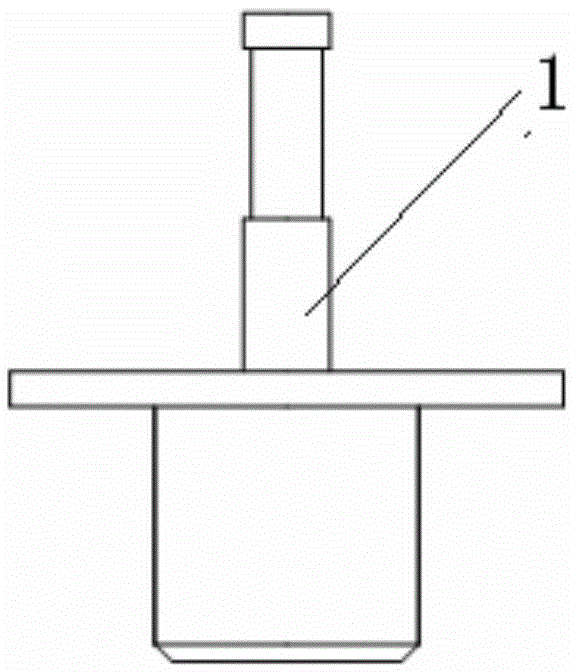

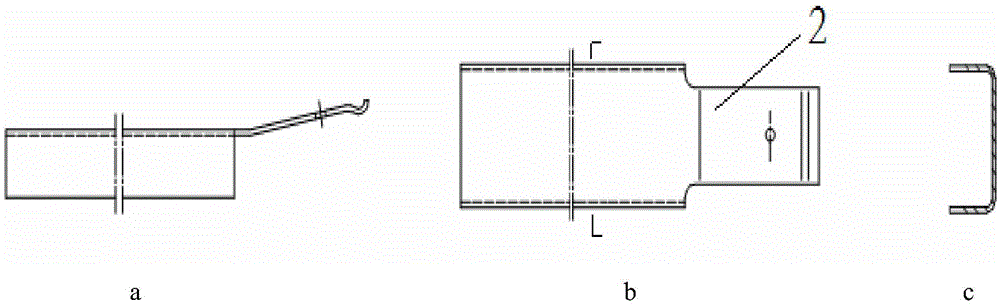

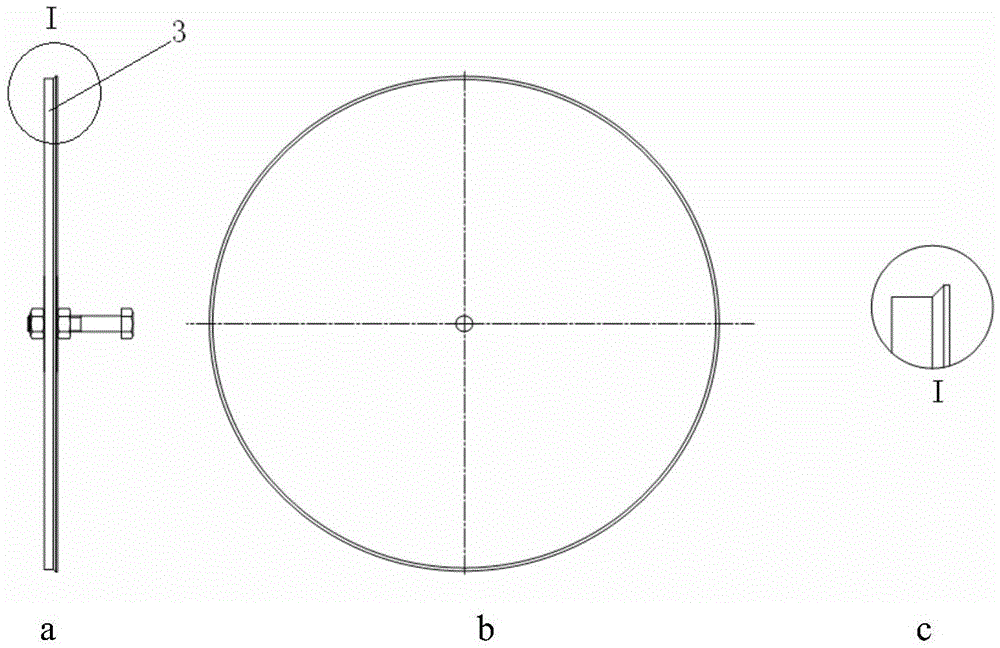

[0036] This embodiment is a combination tool for A320 main wheel paint protection, including light hole protection plug 1, protection sleeve 2, protection cover 3, protection taper sleeve 4, screw hole protection plug 5 and protection plate 6. The light hole protection plug, protection sleeve, protection cover, protection taper sleeve, screw hole protection plug and protection plate are independent parts respectively, and are used in cooperation with the A320 main engine wheel respectively.

[0037] The light hole protection plug 1 has 18 pieces, all of which are used for the paint spraying protection of the tension bolt holes. During use, each protection plug is installed in each of the tension bolt holes.

[0038] The protective cover 2 has 9 pieces, all of which are used for the spray paint protection of the transmission block installation part. When in use, each protective cover is respectively set on the transmission block installation part of the A320 main engine wheel. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com