Improved printing of security devices

A kind of safety equipment and equipment technology, applied in printing, printing process, printing of special varieties of printed matter, etc., can solve problems such as unclear images, blurring, etc., and achieve the effect of reducing ink volume, avoiding use, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

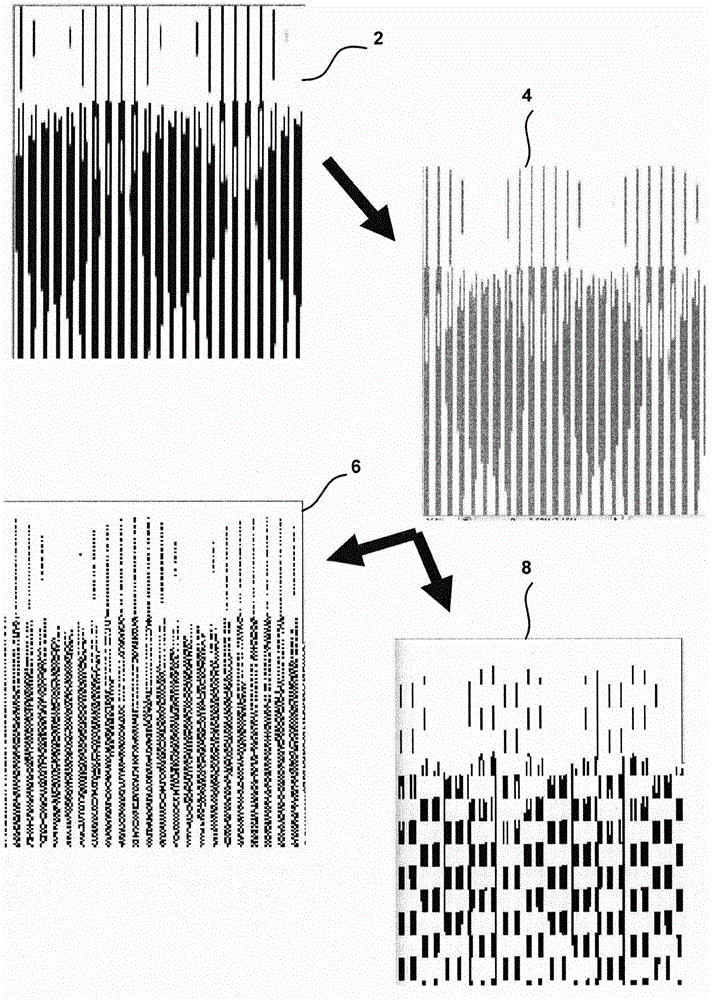

[0059] A method for addressing point gain in interleaved images is disclosed. The method includes a pre-printing operation of selectively blanking image data of pixels in different frames as a means of compensating for the dot gain phenomenon that occurs when printing these images.

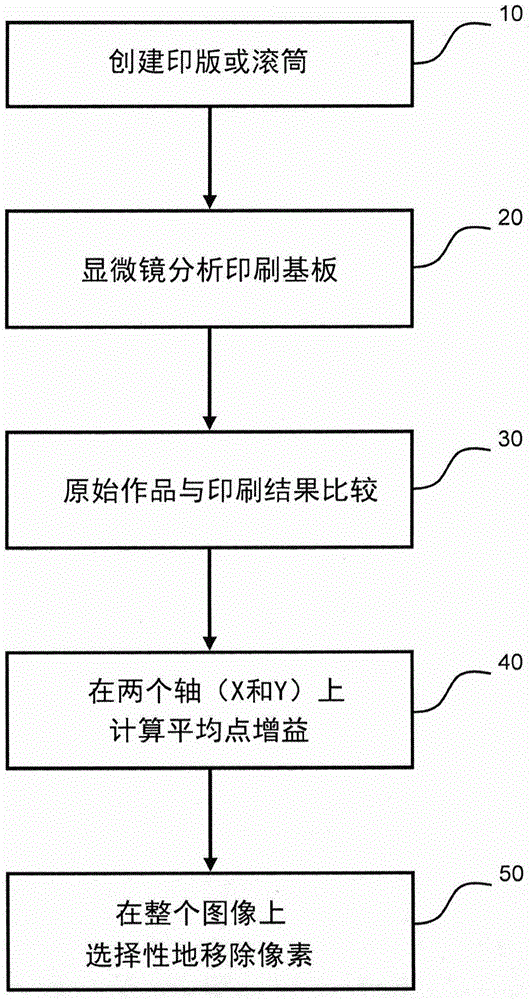

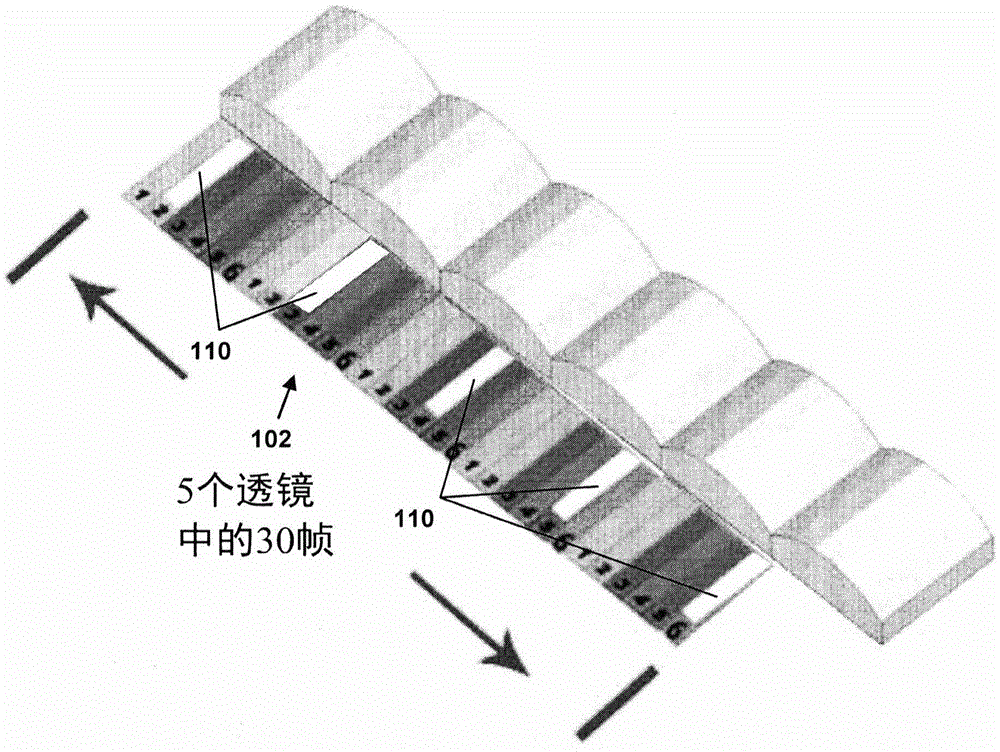

[0060] figure 2 The steps involved in evaluating the dot gain for preparing a composite interlaced image for lenticular printing are described in overview by means of a flowchart. A manual image preparation process was performed, followed by analysis of the data from the manual image preparation. First, in step 10, a "fingerprint" of the impression is taken by using a backing plate to create a printing plate or cylinder. Next, in step 20, the substrate is printed with a series of lines, spots, interlaced images and other images based on the artwork generated in step 10.

[0061] The substrate is then microscopically analyzed, and then in step 30 the original screenshot of the file and / or the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com