Technology for milling roller shafts into flat square products

A technology of roller shaft and flat square, which is applied in the field of roller shaft milling and flat square, to achieve the effect of high product quality, low experience requirement and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

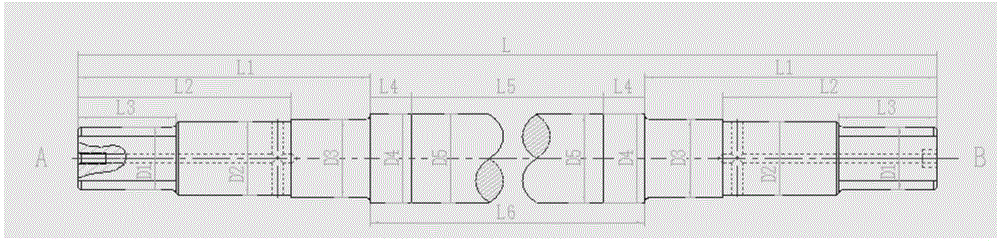

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment:

[0029] A roller shaft milling flat square process, comprising the following processing steps:

[0030] 1) Selection of machine tools:

[0031]

[0032] 2), the choice of measuring tools:

[0033] serial number Gauge type 1、 height gauge 2、 Steel ruler 3、 Caliper

[0034] 3) Selection of tools:

[0035] serial number tool type 1、 T-type platen screw 2、 U-shaped platen 3、 adjustable wrench 4、 needle 5、 V block

[0036] 4) Selection of the speed and feed rate of the machine tool:

[0037] serial number Shaft outer diameter Cutting speed (m / min) Feed rate Mm / r 1、 φ20~φ150 95~118 0.1~0.2

[0038] 5) Clamping:

[0039] First install the T-shaped pressure bar screw on the worktable of the milling machine, then place the V-shaped blocks on both ends of the worktable of the millin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com