Thread processing insert and processing method thereof

A thread machining and thread cutter technology, applied in the field of thread machining inserts and their machining and machining inserts, can solve problems such as low efficiency and cumbersome tool setting process, and achieve the goal of eliminating tool setting process, preventing mutual interference and eliminating shape and position errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

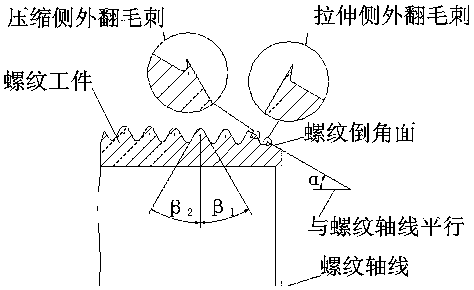

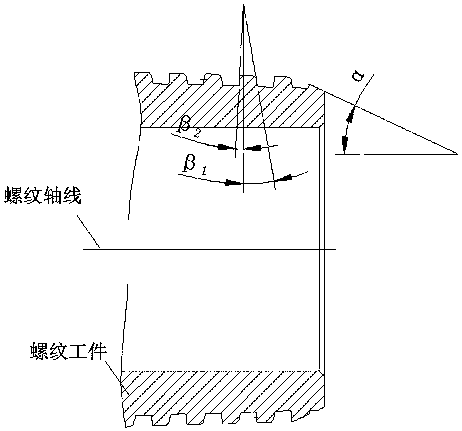

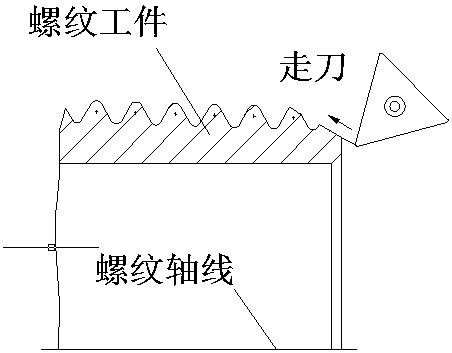

[0029] Such as Figure 5-1 , Figure 5-2 , Figure 6-1 , Figure 6-2 As shown, a thread processing blade includes a blade body 1, the cutting edge side of the blade body is provided with a thread cutting knife 2, and a deburring bayonet 5 is also provided before the thread cutting knife, and the deburring bayonet includes a set The compression side burr cutting edge 3 which is connected to the compression side burr blade and can be used to cut the burrs on the side of the thread tooth profile which bears the tensile load at the front end. Blade 4.

[0030] The angle between the chamfered surface at the beginning of the thread and the thread axis is α, and the angle formed between the side of the tooth profile on the side of the thread tooth that bears the compressive load and the plane perpendicular to the thread axis is β1. The included angle formed between the tooth profile side on the side bearing the tensile load and the perpendicular plane to the thread axis is β2, an...

Embodiment 2

[0040] A kind of thread processing blade comprises a blade body 1, the cutting edge side of the blade body is provided with a thread cutting knife 2, and a deburring bayonet 5 is also provided before the thread cutting knife, and its deburring bayonet includes a front end The compression side burr blade 3 which cuts the burrs on the side of the thread tooth profile bearing the compressive load, and the tension side burr blade 4 which is connected to the compression side burr blade and can be used to cut the burrs on the side of the thread tooth profile which bears the tensile load.

[0041] The angle between the chamfered surface at the beginning of the thread and the thread axis is α, and the angle formed between the side of the tooth profile on the side of the thread tooth that bears the compressive load and the plane perpendicular to the thread axis is β1. The included angle formed between the tooth profile side on the side bearing the tensile load and the perpendicular plan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com