Adjustable and indexable quick positioning and clamping device for machining aviation shell part

A technology for positioning and clamping and housing, applied in positioning devices, metal processing machinery parts, metal processing equipment, etc., can solve the problems of poor economic benefits, difficult clamping, and time-consuming, reducing wear and improving production. Efficiency, effect of improving mutual positional relationship and machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

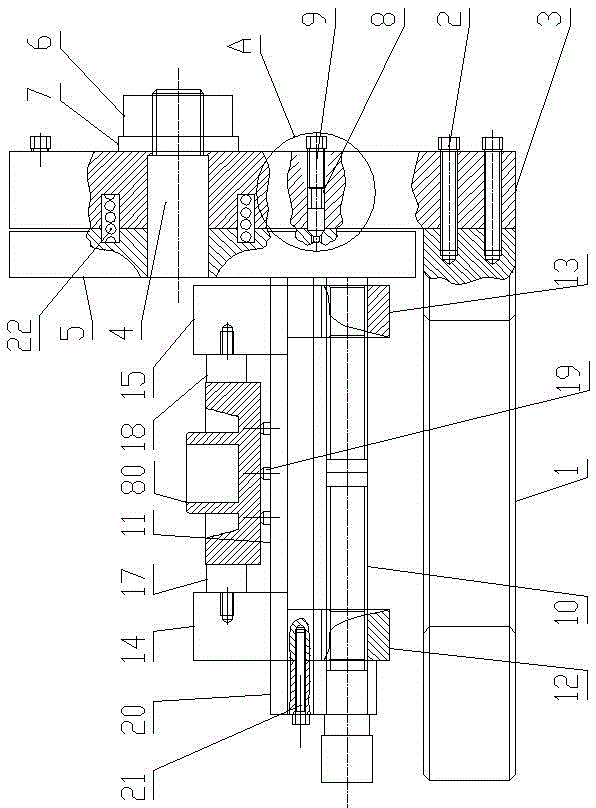

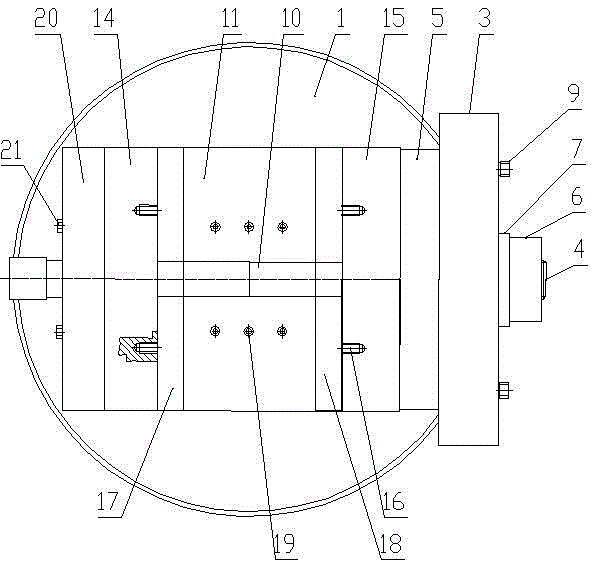

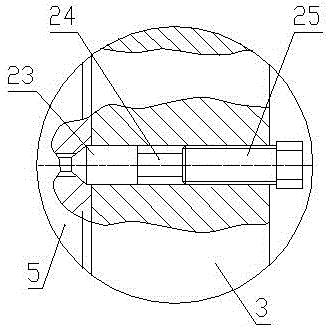

[0024] Embodiment one: if figure 1 , figure 2 , image 3 and Figure 4 As shown, the adjustable and indexable fast positioning clamping device for processing aviation shell parts of the present invention includes a horizontally arranged bottom plate 1, and the right side of the bottom plate 1 is vertically provided with a support plate 3 through fastening bolts 2 to support A rotating shaft 4 is horizontally arranged on the plate 3, and the left end of the rotating shaft 4 is fixedly connected with a mounting plate 5. The mounting plate 5 is located on the left side of the supporting plate 3 and is parallel to the supporting plate 3. The right end of the rotating shaft 4 is threaded with a fastening nut 6, and the fastening nut 6 Through the washer 7 sleeved on the rotating shaft 4, press fit with the right side of the support plate 3;

[0025] The support plate 3 is provided with threaded holes 8 respectively located above, below, in front of, and behind the rotating shaf...

Embodiment 2

[0031] Embodiment two: if Figure 5 As shown, the difference from Embodiment 1 is that both the left clamping block 17 and the right clamping block 18 are formed by bending steel plates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com