Chamfering device for floors

A chamfering and flooring technology, which is applied in the field of flooring manufacturing, can solve the problems of poor grinding effect, small grinding application range, and low efficiency, and achieve the effects of high grinding efficiency, large grinding application range, and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

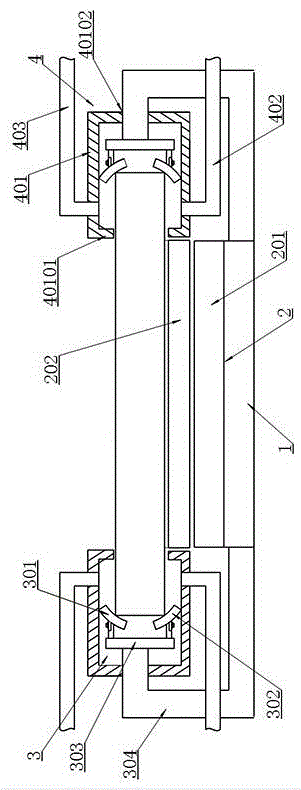

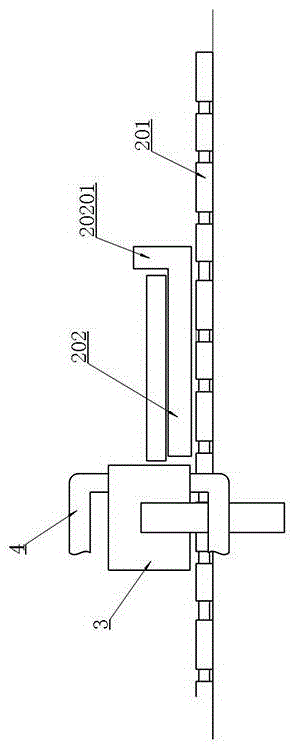

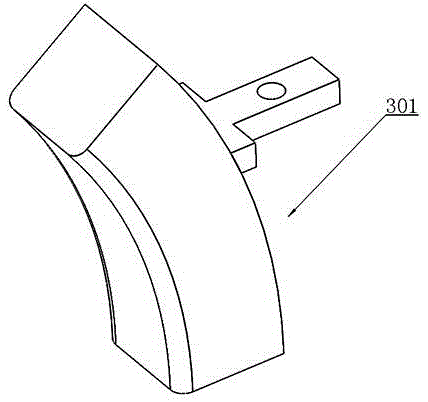

[0021] Example: as attached figure 1 , attached figure 2 and attached image 3 As shown, a chamfering and polishing device for flooring includes a frame 1, a conveying unit 2 arranged on the frame 1, and a chamfering and polishing unit 3 arranged on both sides of the frame 1 and Dust suction unit 4, the chamfering and polishing unit 3 includes an upper chamfering knife 301 and a lower chamfering knife 302, the upper chamfering knife 301 and the lower chamfering knife 302 are arc-shaped chamfering knives, and the suction The dust unit 4 includes a dust suction hood 401 arranged around the chamfering and polishing unit 3 . The grinding process of the chamfering and polishing unit 3 on the floor has the advantages of high grinding efficiency and good effect, and the surrounding setting of the dust suction unit 4 makes it easy to absorb and store the wood chips generated in the grinding process, which has the function of protecting production. Advantages of the working environ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com