Under-actuated highly-simulated finger integrating coupling and adaptive motion modes

A motion mode and under-actuated technology, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of poor self-adaptive ability, insufficient grasping force, and low degree of human imitation, so as to achieve strong self-adaptive ability and reduce energy loss , the effect of reducing muscle fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

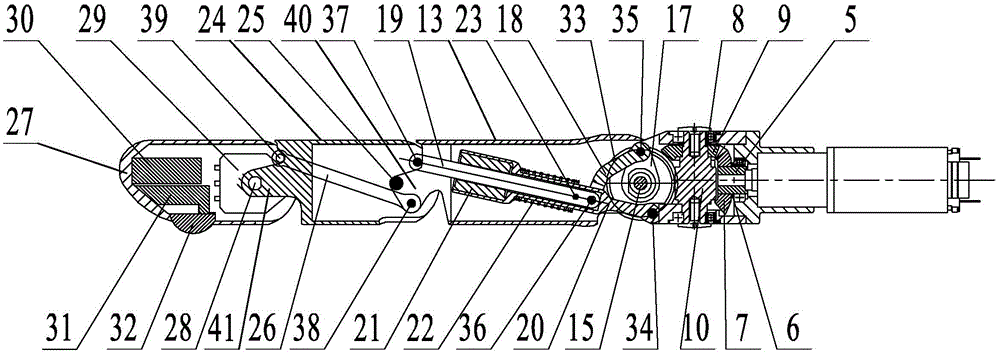

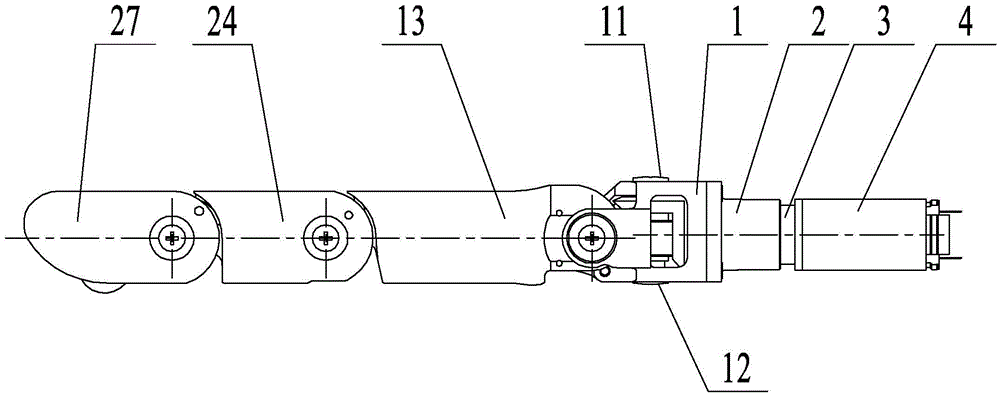

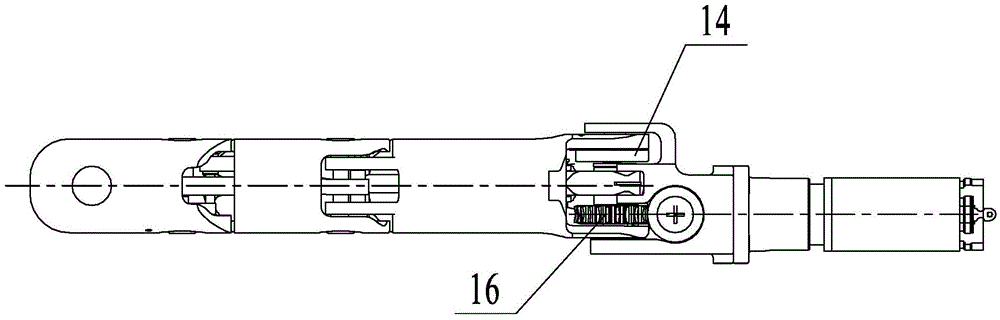

[0021] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Describe this embodiment, this embodiment includes base joint, near phalanx, middle phalanx and far phalanx;

[0022] The base joint includes a base 1, a gear box mount 2, a gear box 3, a motor 4, a bevel gear coupling 5, a first bevel gear 7, a second bevel gear 9 and a worm 10, and the gear box 3 passes through the gear box The mounting seat 2 is fixedly installed on the base 1, and the output shaft of the motor 4 passes through the reduction box 3 and the bevel gear coupling 5 to be connected with the first bevel gear 7 in turn, and the second bevel gear 9 is fixedly installed on the worm 10 and its Mesh with the first bevel gear 7;

[0023] The proximal knuckle includes a first knuckle housing 13, an MCP shaft 15, a turbine 16, a drive rod connection seat 17, a drive rod 18, a slide rod 19, a slide rod base 20 and a linear bearing 21, the first knuck...

specific Embodiment approach 2

[0030] Specific implementation mode two: combination figure 1 Describe this embodiment, in this embodiment, one end of the first knuckle shell 13 in contact with the second knuckle shell 24 is processed with a first connecting protrusion 40, and the first connecting protrusion 40 is arranged on the second knuckle shell 24. In the knuckle shell 24, the first knuckle shell 13 is connected with the second knuckle shell 24 through the first connecting protrusion 40; the end of the second knuckle shell 24 in contact with the third knuckle shell 27 is processed There is a second connection protrusion 41 , and the second knuckle shell 24 is connected with the third knuckle shell 27 through the second connection protrusion 41 .

[0031] In this embodiment, the setting of the first connection protrusion 40 and the second connection protrusion 41 is to ensure that the connection relationship between the first knuckle shell 13, the second knuckle shell 24 and the third knuckle shell 27 i...

specific Embodiment approach 3

[0032] Specific implementation mode three: combination figure 1 Describe this embodiment. In this embodiment, the base joint also includes an input-end bevel gear adjustment washer 6 and an output-end bevel gear adjustment washer 8. The input-end bevel gear adjustment washer 6 is set on the bevel gear coupling 5, the bevel gear adjustment gasket 8 at the output end is set on the worm 10.

[0033]In this embodiment, the setting of the bevel gear adjustment pad 6 at the input end and the bevel gear adjustment pad 8 at the output end is used to adjust the degree of engagement between the first bevel gear 7 and the second bevel gear 9, and the bevel gear adjustment pad at the output end The sheet 8 is composed of a disc type elastic element, which can adjust the position of the meshing point between the worm 10 and the worm 16 and eliminate the ulnar gap between the worm 16 and the worm 10 . Other unmentioned structures and connections are the same as those in the first or second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com