Dismounting and mounting machine for prefabricated box culvert mould core

A technology for disassembling and assembling machines and mold cores, which is applied in the field of construction machinery, can solve the problems that the machine cannot be disassembled and assembled, requires high operating skills, and affects accuracy and stability, and achieves easy maintenance, flexible operation, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] In order to further set forth the technical solution of the present invention, in conjunction with the description, the specific embodiments of the present invention are as follows:

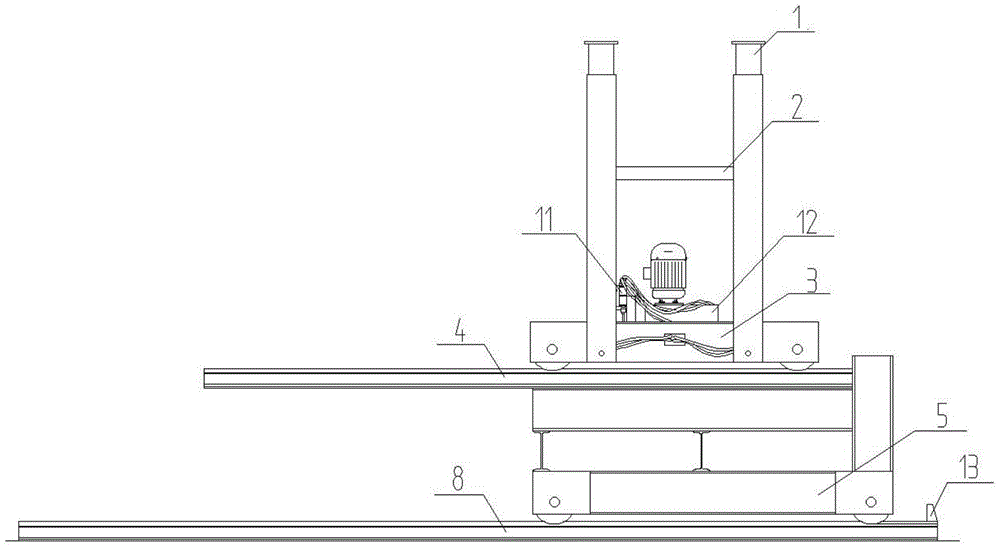

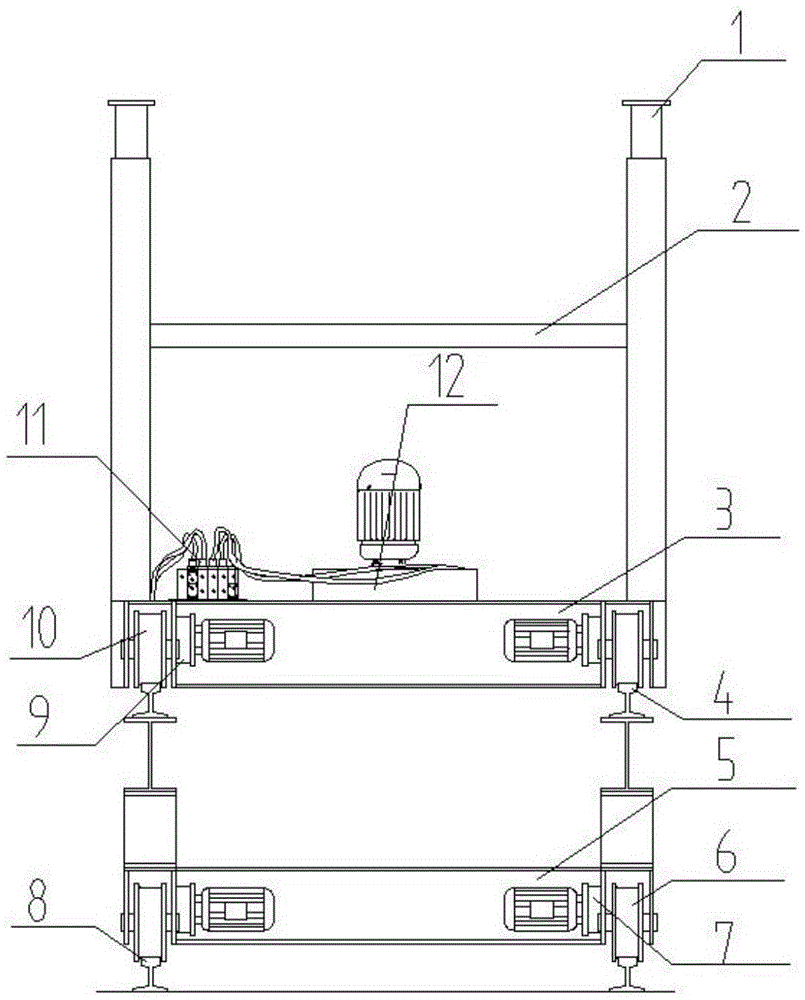

[0024] Such as figure 1 As shown, the present invention discloses a prefabricated box culvert core dismantling machine, which consists of a hydraulic cylinder 1, a hydraulic station 12, a multi-directional valve 11, an upper frame 3, an upper rail 4, The upper wheel 10, the upper wheel drive motor 9, the lower frame 5, the lower track 8, the lower wheel 6, the lower wheel drive motor 7, the hydraulic cylinder support 2 and the gear 13;

[0025] There are four hydraulic cylinders 1, the cylinder body of which is on the bottom, and the push rods face upwards. They are vertically and symmetrically arranged on both sides of the upper frame 3, and are fixedly connected with the upper frame 3; the hydraulic cylinder support 2 is fixedly connected horizontally between every two adjacent hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com