Box-gluing method and box-gluing machine with three-dimensional plug-in sleeves

A folder gluer, three-dimensional technology, applied in container manufacturing machinery, box making operations, paper/cardboard containers, etc., can solve the problems of unstable processing quality, impact on use efficiency, low processing efficiency, etc. The effect of high processing efficiency and stable processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

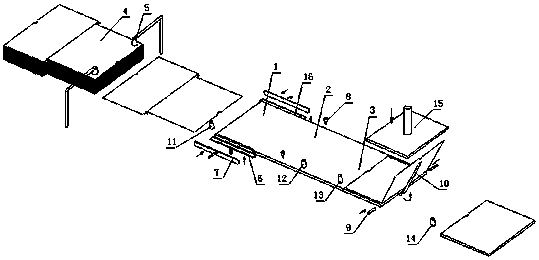

[0028] Attached below figure 1 Further description is made to the folder gluer of the present invention:

[0029] The folder gluer of the present invention comprises a base frame and a controller, and a transmission mechanism connected to the base frame, an up-suction feeder 5, a first processing position 1, and a second processing position, which are respectively communicated with the controller and connected to the base frame. 2 and the third processing position 3. The transfer mechanism connects the suction feeder 5, the first processing position 1, the second processing position 2 and the third processing position 3 in sequence.

[0030] The up-suction feeder 5 automatically picks up the cardboard 4 to be folded by the suction cup, and places the cardboard 4 to be folded on the conveying mechanism to complete the orderly and controllable delivery of a single cardboard 4 to be folded.

[0031] The first processing position 1 is provided with a pneumatic hemming mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com