Part discharging device

A technology of unloading and unloading, which is applied in the field of unloading equipment, can solve the problems of reducing the market competitiveness of enterprises, reducing profits, and reducing the efficiency of operators to take materials, so as to shorten the time required for taking materials and solve the problem of production efficiency decline , The effect of improving the efficiency of material extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

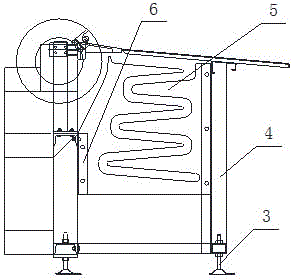

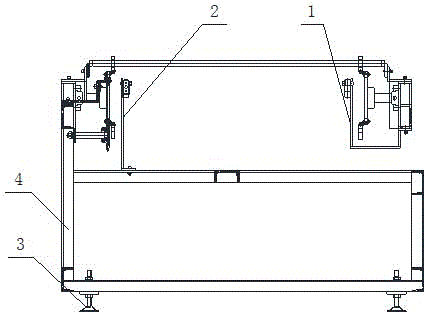

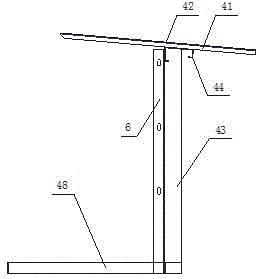

[0021] Example: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , a lowering device, including a tripod 4 and several legs arranged at the bottom thereof, the legs are adjustable feet 3 that can adjust the height, and the tripod 4 is also provided with a blanking mechanism I1 and a blanking mechanism II2, A defective product storage plate 5 is provided between the blanking mechanism I1 and the blanking mechanism II2, and the parts are connected by detachable components; the tripod 4 includes a vertically arranged column 43, and the column 43 is arranged on the On the lower cross brace 48 at the lowermost end, the side plates of the column 43 are arranged side by side to connect the angle steel 6, and the upper beam 44 is arranged at the upper end of the column 43, and the upper beam 44 is connected to the upper guide bar 41, and the surface of the upper guide bar 41 is provided with a soft silicone skin 42. The middle part of 43 is connected wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap