A fully automatic rolling and packaging equipment for heat-shrinkable sheets

A packaging equipment, fully automatic technology, applied in the directions of packaging, transportation and packaging, winding strips, etc., can solve the problems of easy lifting of sheets, inability to fit screen printing screens, waste of time, etc., and achieve breakthroughs in inconsistent manual operations. Inconsistency with standards, reducing the probability of human quality hidden dangers, and reducing the effect of human resource requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the following will further describe in detail the products of the present invention in conjunction with the examples.

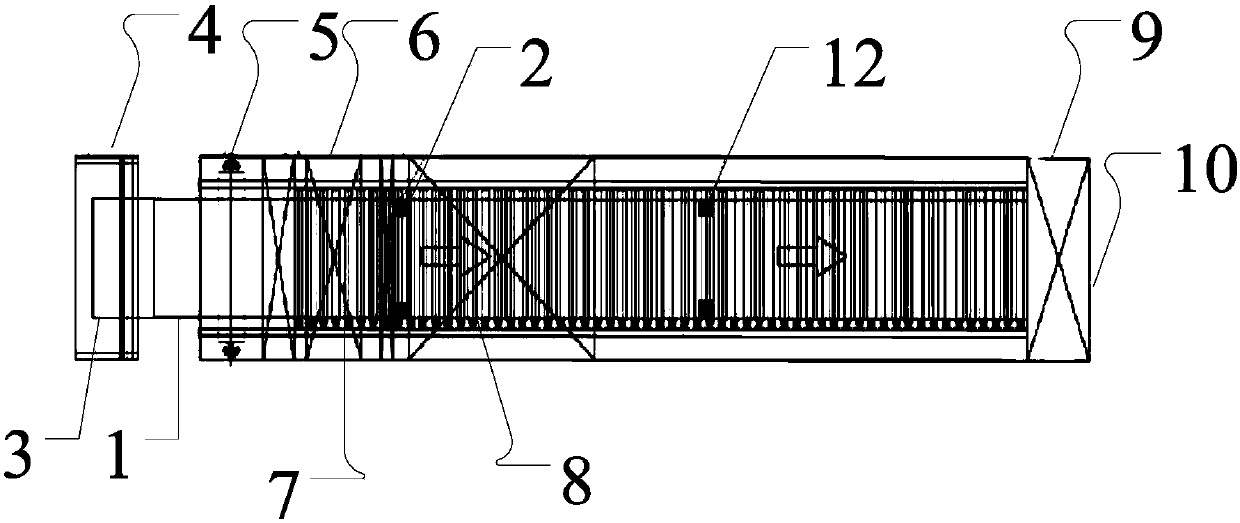

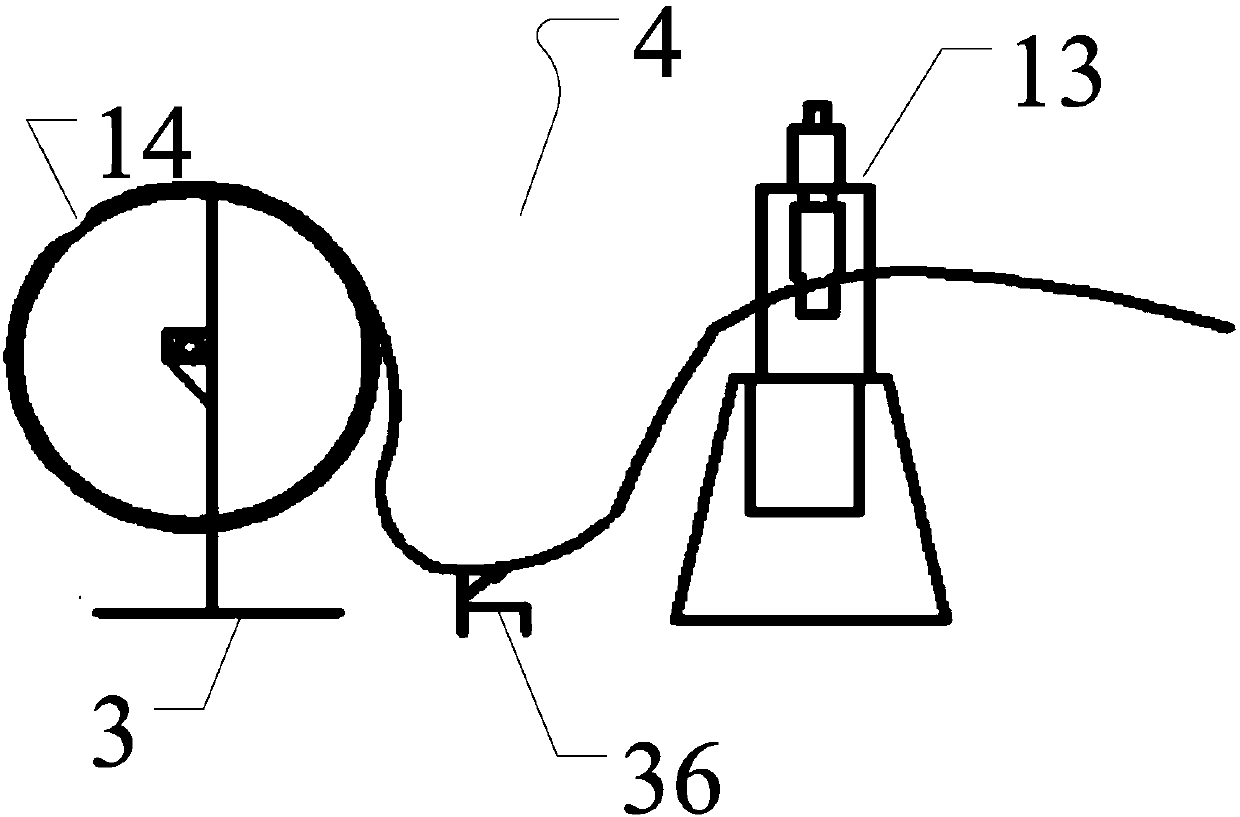

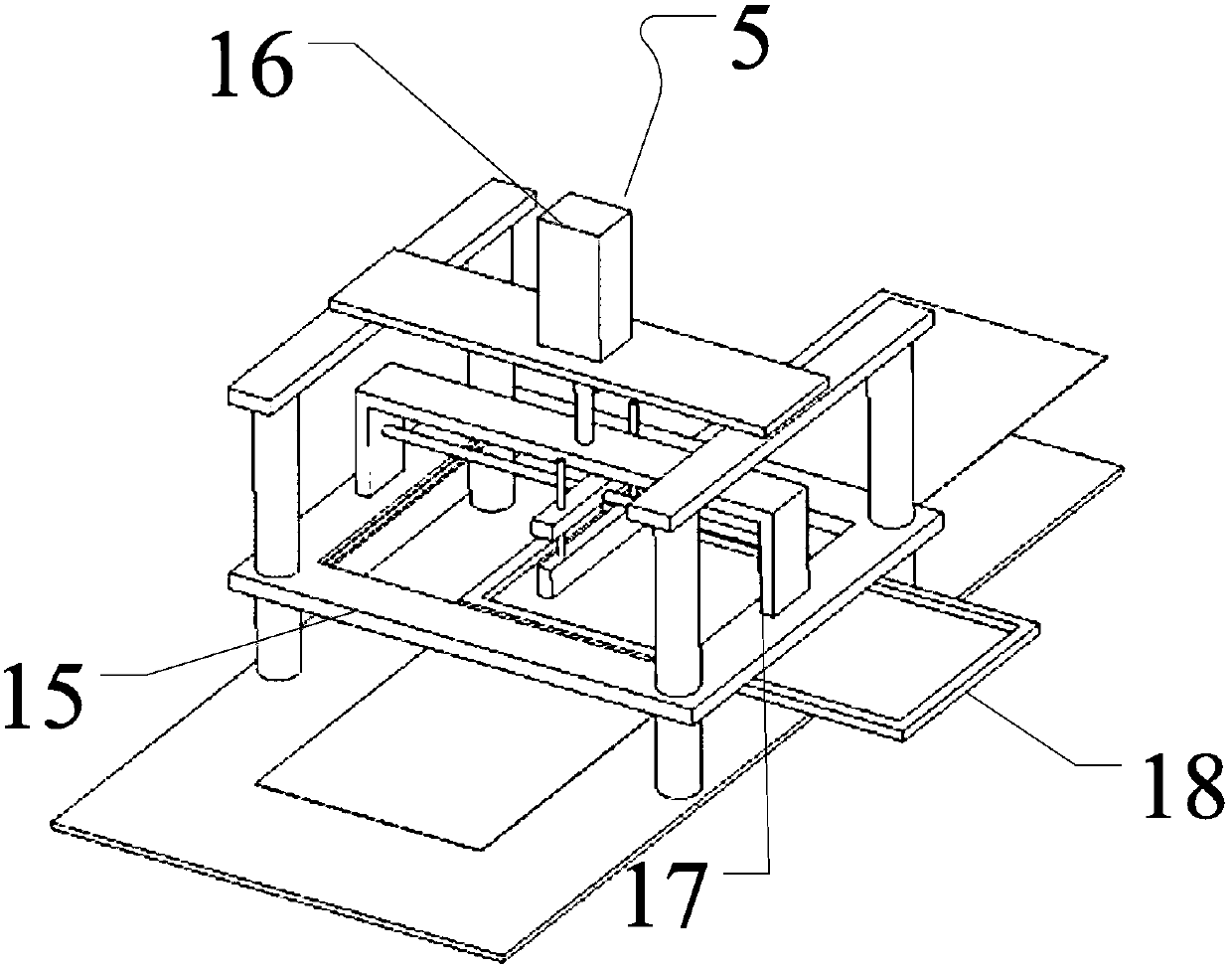

[0035] Such as figure 1As shown, the present invention discloses a fully automatic rolling and packaging equipment for heat-shrinkable sheets, including a machine 1, a sheet material transmission mechanism, a sheet material coil fixing frame 3, an automatic sheet material discharging mechanism 4, and a trademark printing mechanism 5. Sheet material cutting mechanism 6, sheet material cutting and chamfering mechanism 7, sheet material drying mechanism 8, sheet material winding mechanism 9, viscose mechanism 10 and sheet material discharging mechanism, the sheet material coil fixing frame 3 It is arranged at the front end of the machine 1, the sheet material discharge mechanism is arranged at the rear end of the machine 1, the sheet automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com