A high -efficiency sewage treatment agent and its preparation methods and applications

A sewage treatment agent and treatment agent technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of high cost, unsatisfactory treatment effect, waste of manpower and material resources, etc., to achieve low production cost, good effect, purification fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

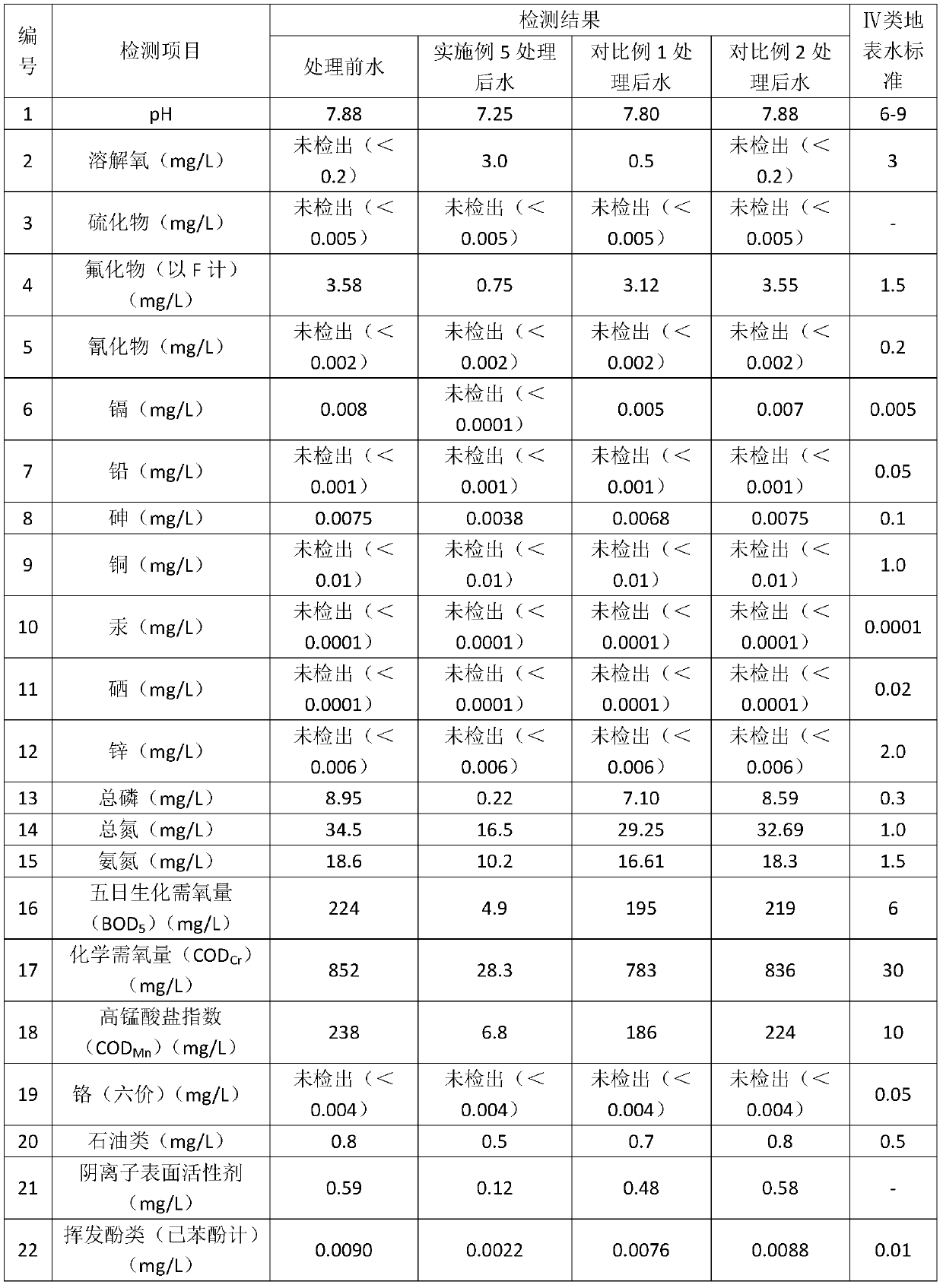

Examples

Embodiment 1

[0017] In the embodiment of the present invention, a high-efficiency sewage treatment agent is composed of the following raw materials in parts by weight: 5 parts of hemp seed, 35 parts of polypropylene resin, 80 parts of hydrogen peroxide, and 22 parts of jujube wood.

[0018] The polypropylene resin was pulverized, passed through a 150-mesh sieve, mixed with hydrogen peroxide, and heated at 50°C for 20 minutes to prepare mixture A for use. Crush hemp seeds and jujube, pass through a 60-mesh sieve, add 80% absolute ethanol with a volume concentration 10 times the mass of the two, and conduct ultrasonic treatment at 75°C for 40 minutes with an ultrasonic power of 800W to prepare mixture B. Heat and stir mixture B at 90°C until dry, then lower it to 50°C, mix it with mixture A, and stir at this temperature for 30 minutes, then raise the temperature to 70°C and continue stirring for 20 minutes, then dry at 85°C That is, high-efficiency sewage treatment agent.

Embodiment 2

[0020] In the embodiment of the present invention, a high-efficiency sewage treatment agent is composed of the following raw materials in parts by weight: 12 parts of hemp seed, 42 parts of polypropylene resin, 100 parts of hydrogen peroxide, and 32 parts of jujube wood.

[0021] The polypropylene resin was pulverized, passed through a 200-mesh sieve, mixed with hydrogen peroxide, and heated at 60°C for 30 minutes to prepare mixture A for use. Crush hemp seeds and jujube, pass through a 100-mesh sieve, add 90% absolute ethanol with 12 times the mass of the two, and conduct ultrasonic treatment at 80°C for 60 minutes with an ultrasonic power of 1000W to prepare mixture B. Heat and stir mixture B at 100°C until dry, then lower it to 60°C, mix it with mixture A, and stir at this temperature for 40 minutes, then raise the temperature to 80°C and continue stirring for 30 minutes, then dry at 90°C That is, high-efficiency sewage treatment agent.

Embodiment 3

[0023] In the embodiment of the present invention, a high-efficiency sewage treatment agent is composed of the following raw materials in parts by weight: 7 parts of hemp seed, 37 parts of polypropylene resin, 85 parts of hydrogen peroxide, and 24 parts of jujube wood.

[0024] The polypropylene resin was pulverized, passed through a 200-mesh sieve, mixed with hydrogen peroxide, and heated at 55°C for 25 minutes to prepare mixture A for use. Crush hemp seed and jujube, pass through a 100-mesh sieve, add 85% absolute ethanol with 11 times the mass of the two, and conduct ultrasonic treatment at 80°C for 50 minutes with an ultrasonic power of 1000W to prepare mixture B. Heat and stir mixture B at 100°C until dry, then lower it to 55°C, mix it with mixture A, and stir at this temperature for 35 minutes, then raise the temperature to 75°C and continue stirring for 25 minutes, then dry at 90°C That is, high-efficiency sewage treatment agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com