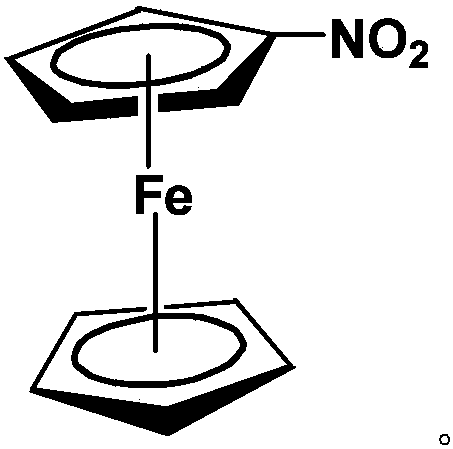

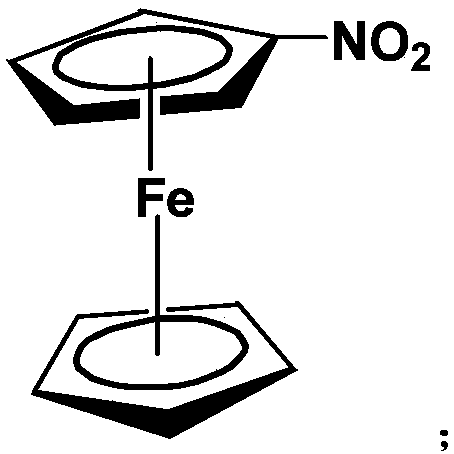

Application of Composite Solution of β-Cyclodextrin and Nitroferrocene in Microcontact Printing

A nitroferrocene and micro-contact printing technology, which is applied in application, printing, printing devices, etc., can solve the problems that have not been reported in the application, and achieve improved coordination and binding, good biocompatibility, and tight binding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Application of β-cyclodextrin and nitroferrocene composite solution in microcontact printing, including:

[0028] Step 1, carboxylation of the substrate, soak the polypropylene substrate in 45% isopropanol aqueous solution for 30 minutes, then soak it in 2mol / L sulfuric acid at 55°C for 15 minutes, then wash it with water, and dry it in vacuum at 60°C to obtain carboxylated polypropylene base.

[0029] Step 2, preparing a composite solution of β-cyclodextrin and nitroferrocene, dissolving β-cyclodextrin in water to obtain an aqueous solution of β-cyclodextrin with a concentration of 3g / L, in every liter of β-cyclodextrin aqueous solution Add 0.8 g of nitroferrocene, and ultrasonicate at 20 kHz for 30 minutes to obtain a uniformly dispersed composite solution of β-cyclodextrin and nitroferrocene.

[0030] Step 3, microcontact printing, soak the PDMS stamp in the composite solution of β-cyclodextrin and nitroferrocene for 30s, take it out and put it in N 2 Dry in the ai...

Embodiment 2

[0033] Application of β-cyclodextrin and nitroferrocene composite solution in microcontact printing, including:

[0034] Step 1, carboxylation of the substrate, soaking the polypropylene substrate in 50% isopropanol aqueous solution for 50 minutes, then soaking in 2.5mol / L sulfuric acid at 55-65°C for 20 minutes, then washing with water, drying in vacuum at 60°C to obtain carboxyl groups Polypropylene base.

[0035] Step 2, preparing a composite solution of β-cyclodextrin and nitroferrocene, dissolving β-cyclodextrin in water to obtain a β-cyclodextrin aqueous solution with a concentration of 5g / L, in every liter of β-cyclodextrin aqueous solution Add 0.8 g of nitroferrocene, and ultrasonicate at 20 kHz for 50 minutes to obtain a uniformly dispersed composite solution of β-cyclodextrin and nitroferrocene.

[0036] Step 3, microcontact printing, soak the PDMS stamp in the composite solution of β-cyclodextrin and nitroferrocene for 35s, take it out and put it in N 2 Dry in air...

Embodiment 3

[0039] Application of β-cyclodextrin and nitroferrocene composite solution in microcontact printing, including:

[0040] Step 1, carboxylation of the substrate, soaking the polypropylene substrate in 55% isopropanol aqueous solution for 60 minutes, then soaking in 3mol / L sulfuric acid at 55-65°C for 20 minutes, then washing with water, drying in vacuum at 65°C to obtain carboxylation Polypropylene base.

[0041]Step 2, preparing a composite solution of β-cyclodextrin and nitroferrocene, dissolving β-cyclodextrin in water to obtain an aqueous solution of β-cyclodextrin with a concentration of 6g / L, in every liter of β-cyclodextrin aqueous solution Add 0.8 g of nitroferrocene, and ultrasonicate at 20 kHz for 60 minutes to obtain a uniformly dispersed β-cyclodextrin and nitroferrocene composite solution.

[0042] Step 3, microcontact printing, soak the PDMS stamp in the composite solution of β-cyclodextrin and nitroferrocene for 40s, take it out and put it in N 2 Dry in the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com