Cationic type degreaser for polymer flooding produced water treatment

A cationic, effluent treatment technology, applied in mining wastewater treatment, added substance water/sewage treatment, water/sewage treatment, etc. It can meet the environmental protection and oilfield development, easy to obtain and transport and save, and improve the efficiency of oil removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Degreaser B 1 and its preparation method

[0032] (1) Degreaser B 1 The composition and components are as follows:

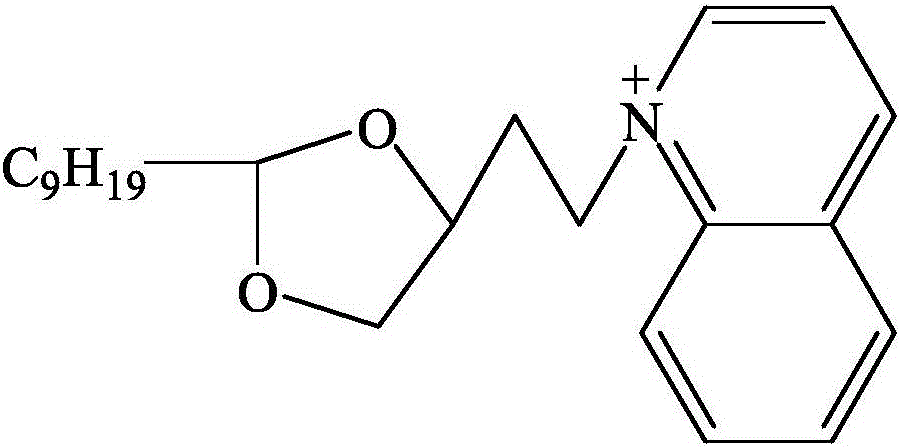

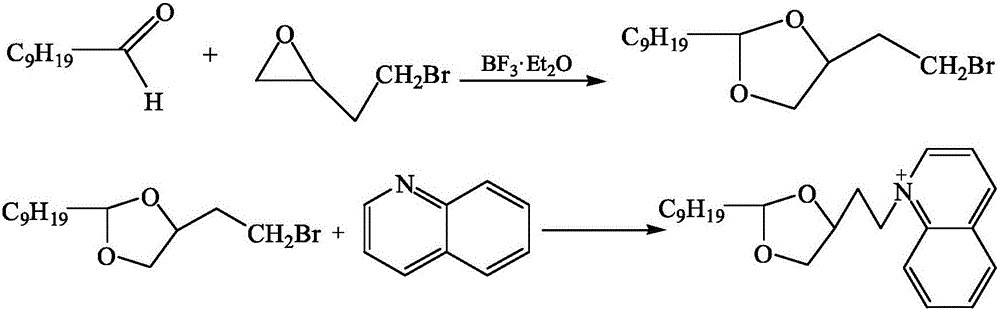

[0033] The degreasing agent is formed by the reaction of n-decyl aldehyde with bromobutane epoxy under the catalysis of boron trifluoride ether solution to form an intermediate, and then reacts with quinoline to form a cationic degreasing agent. Its molecular formula is as follows:

[0034]

[0035] Wherein, the molar ratio of n-decyl aldehyde, epoxybromobutane and quinoline is 1:0.75:0.6.

[0036] (2) Degreaser B 1 The preparation method is as follows:

[0037] ①Add 1 mol of n-decyl aldehyde to a four-necked flask equipped with a reflux condenser, stirrer and thermometer, then add 2340g of carbon tetrachloride, heat up to 38°C, stir for 10min at a stirring rate of 160rpm, then add 0.156g For a boron trifluoride ether solution with a mass concentration of 30%, place 0.75 mol of epoxybromobutane in a constant pressure dropping funnel,...

Embodiment 2

[0040] Embodiment 2: Degreaser B 2 and its preparation method

[0041] (1) Degreaser B 2 The composition and components are as follows:

[0042] The degreasing agent is formed by the reaction of n-decyl aldehyde with bromobutane epoxy under the catalysis of boron trifluoride ether solution to form an intermediate, and then reacts with quinoline to form a cationic degreasing agent. Its molecular formula is as follows:

[0043]

[0044] Wherein, the molar ratio of n-decyl aldehyde, epoxybromobutane and quinoline is 1:1.25:0.8.

[0045] (2) Degreaser B 2 The preparation method is as follows:

[0046] ①Add 1 mol of n-decylaldehyde to a four-necked flask equipped with a reflux condenser, agitator and a thermometer, then add 2750g of acetonitrile, heat up to 35°C, stir at a stirring rate of 100rpm for 15min, then add 0.312g of acetonitrile with a mass concentration of 30 % boron trifluoride ether solution, put 1.25mol of epoxybromobutane in a constant pressure dropping funnel,...

Embodiment 3

[0049] Embodiment 3: Degreaser B 3 and its preparation method

[0050] (1) Degreaser B 3 The composition and components are as follows:

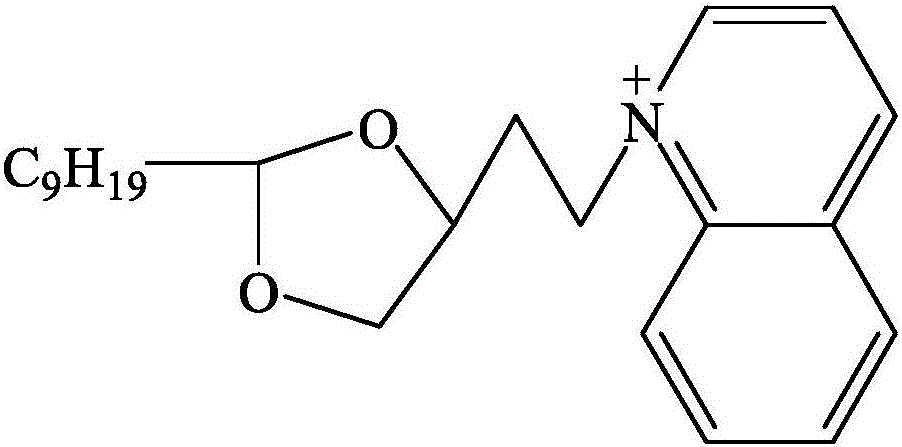

[0051] The degreasing agent is formed by the reaction of n-decyl aldehyde with bromobutane epoxy under the catalysis of boron trifluoride ether solution to form an intermediate, and then reacts with quinoline to form a cationic degreasing agent. Its molecular formula is as follows:

[0052]

[0053] Wherein, the molar ratio of n-decyl aldehyde, epoxybromobutane and quinoline is 1:1.5:1.2.

[0054] (2) Degreaser B 3 The preparation method is as follows:

[0055] ①Add 1 mol of n-decylaldehyde to a four-neck flask equipped with a reflux condenser, agitator and a thermometer, then add 3120g of carbon tetrachloride, heat up to 40°C, stir for 20min at a stirring rate of 200rpm, then add 0.225g For a boron trifluoride ether solution with a mass concentration of 30%, place 1.5 mol of epoxybromobutane in a constant-pressure dropping funnel, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com