Application of alkaline polishing solution in improving surface roughness of barrier layer in CMP

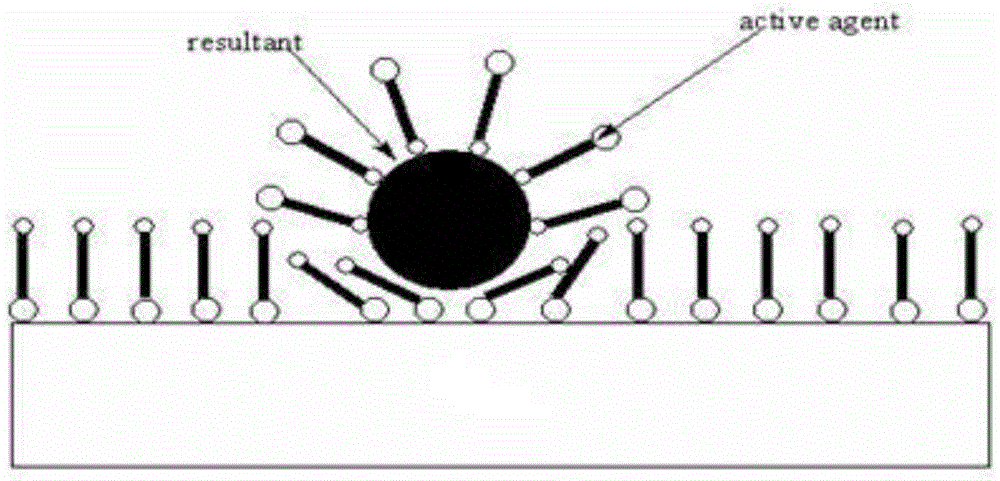

A technology of surface roughness and polishing liquid, applied in polishing compositions containing abrasives, etc., to reduce surface roughness, speed up mass transfer, and achieve the effect of flattening the polishing surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

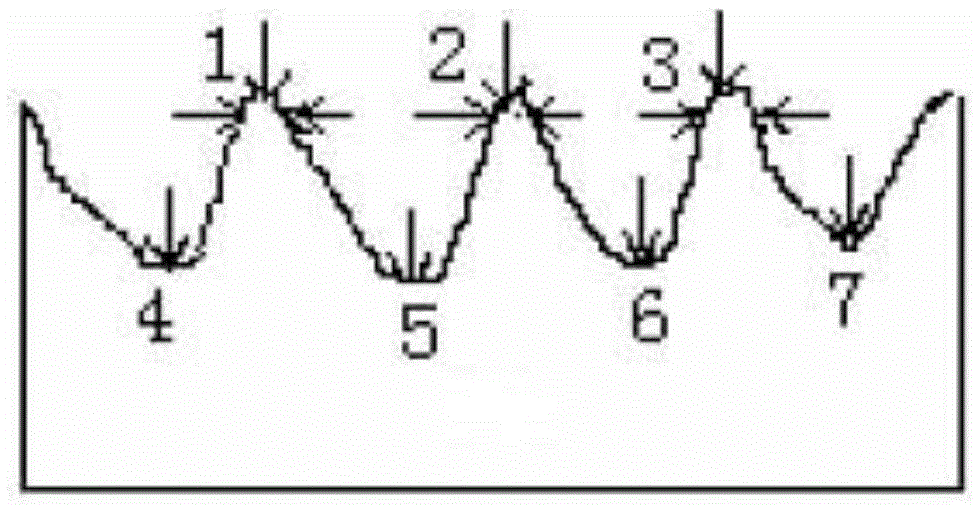

Method used

Image

Examples

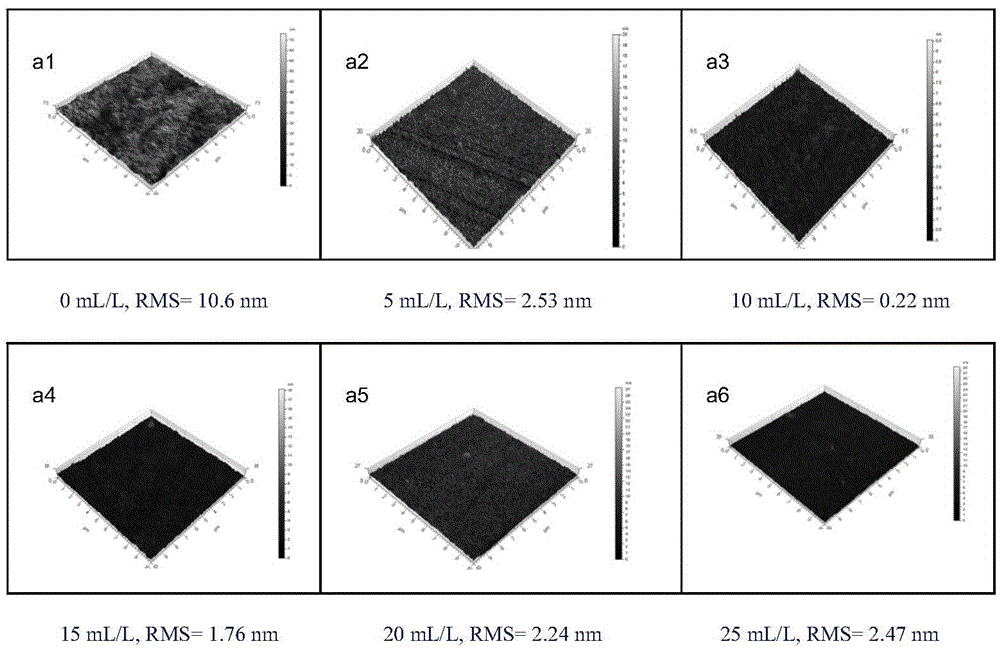

Embodiment 1

[0023] Put 1ml of FA / OⅡ chelating agent into 400ml of ultrapure water, then pour 0ml of FA / OⅠsurfactant into the ultrapure water, stir continuously during the process, add a small amount of ultrapure water to make it solution after it is completely mixed The volume reaches 500ml, and then these mixed solutions are poured into 500ml of SiO 2 In the hydrosol, stir continuously during the process until it is completely poured. Then under the process of working pressure: 27.4kpa; polishing head / polishing disc speed: 105 / 100rpm; flow rate: 150mL / min, the graphic sheet is polished for 180s, and the surface roughness of the barrier layer is checked with an atomic force microscope after polishing;

Embodiment 2

[0025] Put 1ml of FA / OⅡ chelating agent into 400ml of ultrapure water, then pour 5ml of FA / OⅠsurfactant into the ultrapure water, stir continuously during the process, add a small amount of ultrapure water to make it solution after it is completely mixed The volume reaches 500ml, and then these mixed solutions are poured into 500ml of SiO 2 In the hydrosol, stir continuously during the process until it is completely poured. Then under the process of working pressure: 27.4kpa; polishing head / polishing disc speed: 105 / 100rpm; flow rate: 150mL / min, the graphic sheet is polished for 180s, and the surface roughness of the barrier layer is checked with an atomic force microscope after polishing;

Embodiment 3

[0027] Put 1ml of FA / OⅡ chelating agent into 400ml of ultrapure water, then pour 10ml of FA / OⅠsurfactant into the ultrapure water, stir continuously during the process, after it is completely mixed, add a small amount of ultrapure water to make it solution The volume reaches 500ml, and then these mixed solutions are poured into 500ml of SiO 2 In the hydrosol, stir continuously during the process until it is completely poured. Then under the process of working pressure: 27.4kpa; polishing head / polishing disc speed: 105 / 100rpm; flow rate: 150mL / min, the graphic sheet is polished for 180s, and the surface roughness of the barrier layer is checked with an atomic force microscope after polishing;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap