Beer rich in hops aroma and preparation method of beer rich in hops aroma

A beer and flower aroma technology, which is applied to beer fermentation methods, wort preparation, microorganism-based methods, etc., can solve the problems of rough taste, inconspicuous hop aroma, weak taste, etc. Coordinate and solve the effect of weak taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

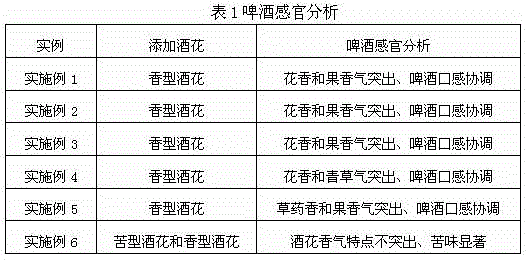

Examples

Embodiment 1

[0029] A beer with strong hop aroma, comprising the following raw materials in proportion by weight: 230 parts of barley malt, 4.5 parts of caramel malt, 0.6 part of aromatic hops, 1.0 part of brewer's yeast dry powder, and 1000 parts of water. Aroma hops are Saaz.

[0030] The preparation method comprises the following steps:

[0031] (1) Crush 230 parts by weight of barley malt and 4.5 parts by weight of caramelized malt into malt powder with broken skin but not broken, put it into a mash pot with 1000 parts by weight of water in advance, and go through three saccharification heat preservation processes in sequence: 53 ℃ for 45 minutes, 65 ℃ for 50 minutes, 72 ℃ for 15 minutes to obtain mash;

[0032] (2) The saccharification mash is circulated and filtered until the wort is clear, and the wheat grains are filtered again with the washing water, and the filtrate is collected twice and poured into the boiling pot;

[0033] (3) Heat and boil for 60 minutes, control the final ...

Embodiment 2

[0037] A beer with strong hop aroma, comprising the following raw materials in proportion by weight: 240 parts of barley malt, 5 parts of caramel malt, 0.66 part of aromatic hops, 1.5 parts of brewer's yeast dry powder, and 1000 parts of water. Aroma hops are Saaz.

[0038] The preparation method comprises the following steps:

[0039] (1) Crush 240 parts by weight of barley malt and 5 parts by weight of caramelized malt into malt powder with broken skin but not broken, put it into a mash pot with 1000 parts by weight of water in advance, and go through three saccharification heat preservation processes in sequence: 53 ℃ for 45 minutes, 65 ℃ for 50 minutes, 72 ℃ for 15 minutes to obtain mash;

[0040] (2) The saccharification mash is circulated and filtered until the wort is clear, and the wheat grains are filtered again with the washing water, and the filtrate is collected twice and poured into the boiling pot;

[0041] (3) Heat and boil for 60 minutes, control the final wo...

Embodiment 3

[0045] A beer with strong hop aroma, comprising the following raw materials in proportion by weight: 220 parts of barley malt, 4 parts of caramel malt, 0.54 part of aromatic hops, 0.5 part of brewer's yeast dry powder, and 1000 parts of water. Aroma hops are Saaz.

[0046] The preparation method comprises the following steps:

[0047] (1) Grind 220 parts by weight of barley malt and 4 parts by weight of caramel malt into malt powder with broken skin but not broken, put it into a mash pot with 1000 parts by weight of water in advance, and go through three saccharification heat preservation processes in sequence: 53 ℃ for 45 minutes, 65 ℃ for 50 minutes, 72 ℃ for 15 minutes to obtain mash;

[0048] (2) The saccharification mash is circulated and filtered until the wort is clear, and the wheat grains are filtered again with the washing water, and the filtrate is collected twice and poured into the boiling pot;

[0049] (3) Heat and boil for 60 minutes, control the final wort vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com