Fabricated prestressed concrete hollow slab and cast-in-place beam integrated construction method

A construction method and concrete technology, applied in the direction of floors, building materials, building components, etc., can solve the problems of slow construction speed, floor height difference, affecting project quality, etc., to enhance the force capacity and integrity, shorten the construction time, The effect of speeding up the progress of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

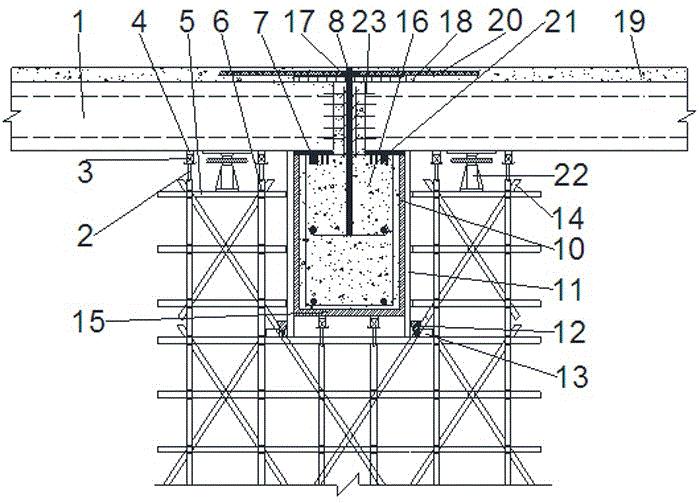

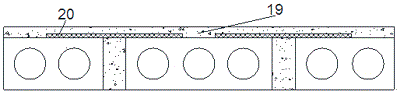

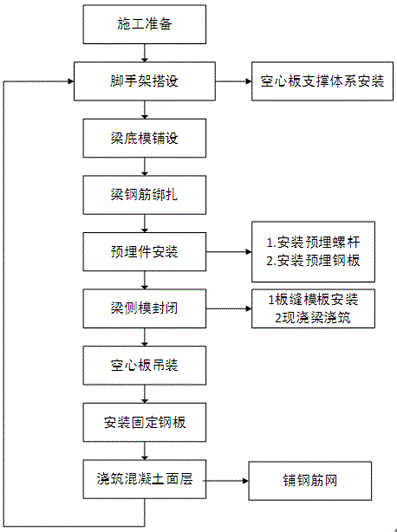

[0036] Scaffold 5 is connected by bowl buckle 6, the support point is set at 300-400mm from the end of the board, the distance between the poles is 600mm, and diagonal braces 14 are set at a horizontal distance of 400mm. Adjustable jackscrew bolt 2, and laid 100mm 100mm wooden square 3; the size of the steel bar is determined according to the design value, and the two sides of the top of the beam steel bar 9 are respectively welded with a 16mm thick pre-embedded steel plate 7, which is segmented; the bottom of the pre-embedded steel plate 7 is welded with studs 21; M50 pre-embedded screw rods 8 with a length of 40cm are installed at intervals, and the pre-embedded screw rods 8 are bound and fixed with the beam steel bar 9 on the main body with binding wires; when hoisting, the angle between the steel wire rope and the plate shall not be less than 50o, if such an angle cannot meet the requirements, use Auxiliary by iron poles; prestressed concrete hollow slab 1 is leveled with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com