Runner leveling process of utility-type unit

A technology of large units and runners, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of heavy workload and low efficiency, and achieve the effects of improving accuracy, collecting data quickly, and shortening calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

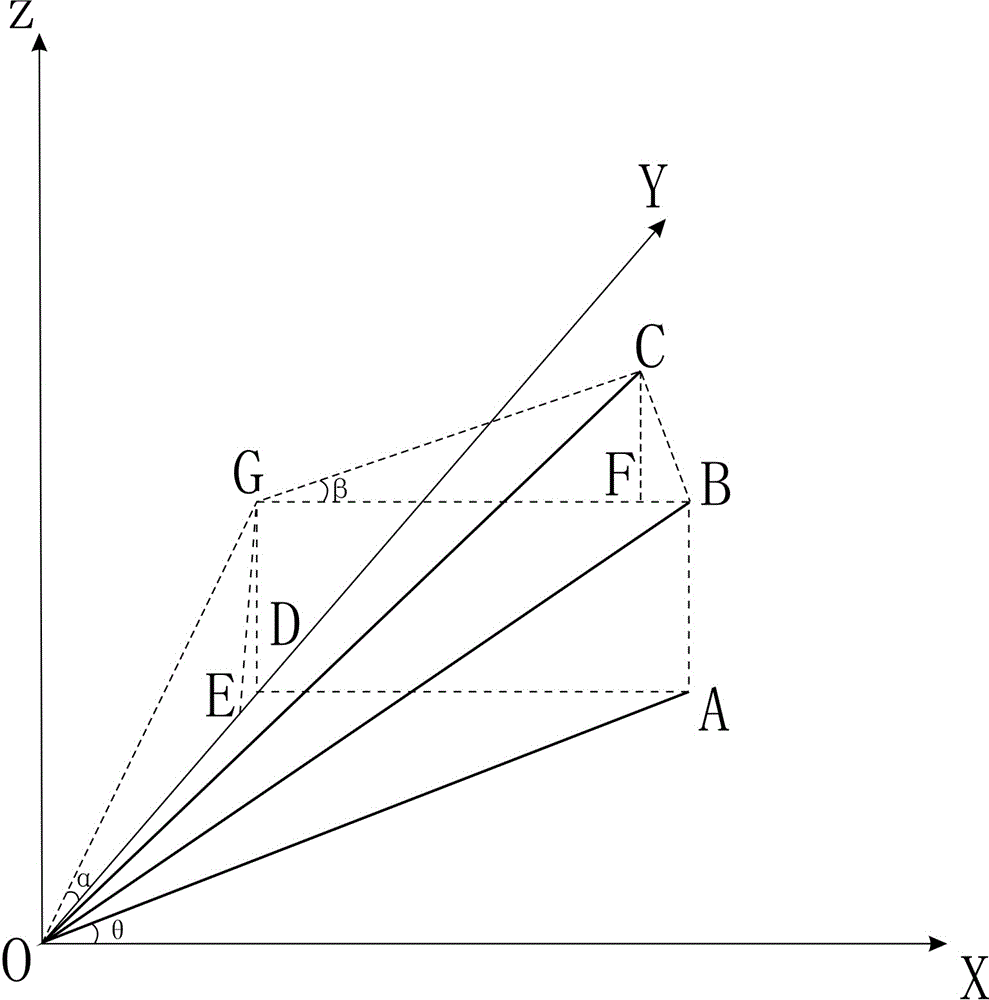

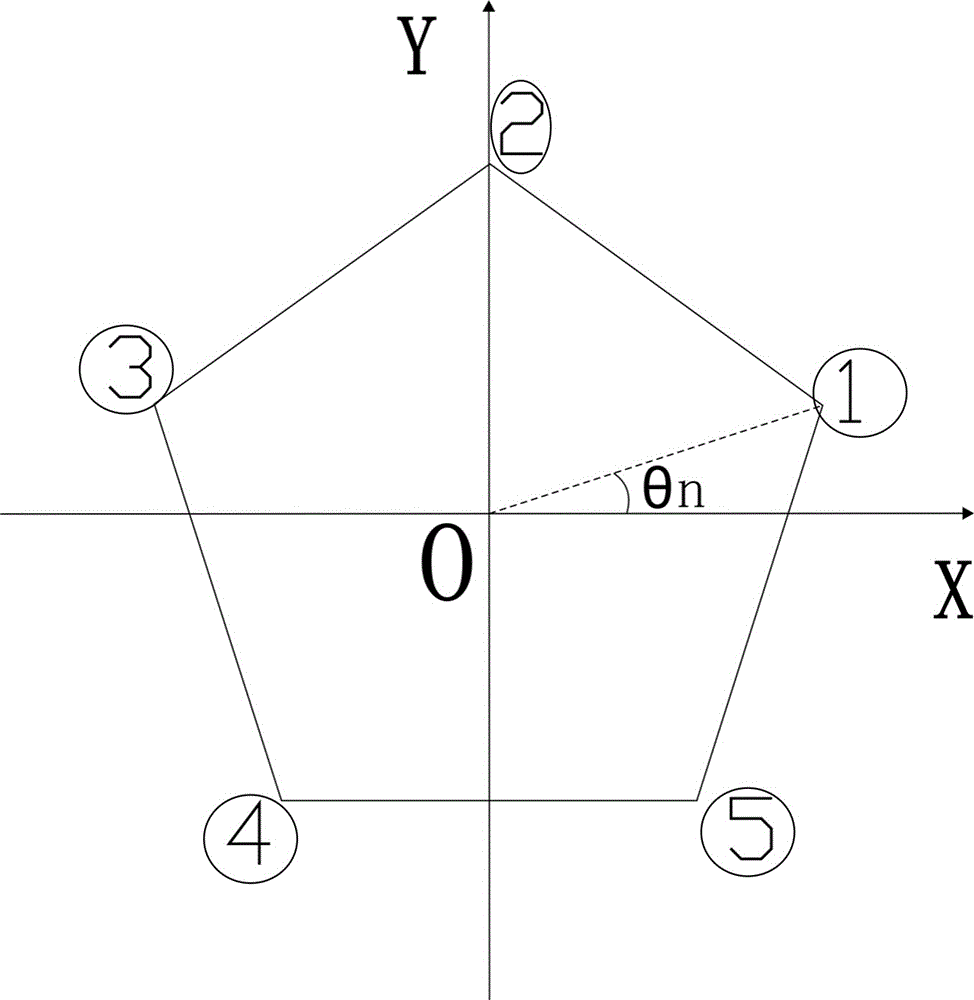

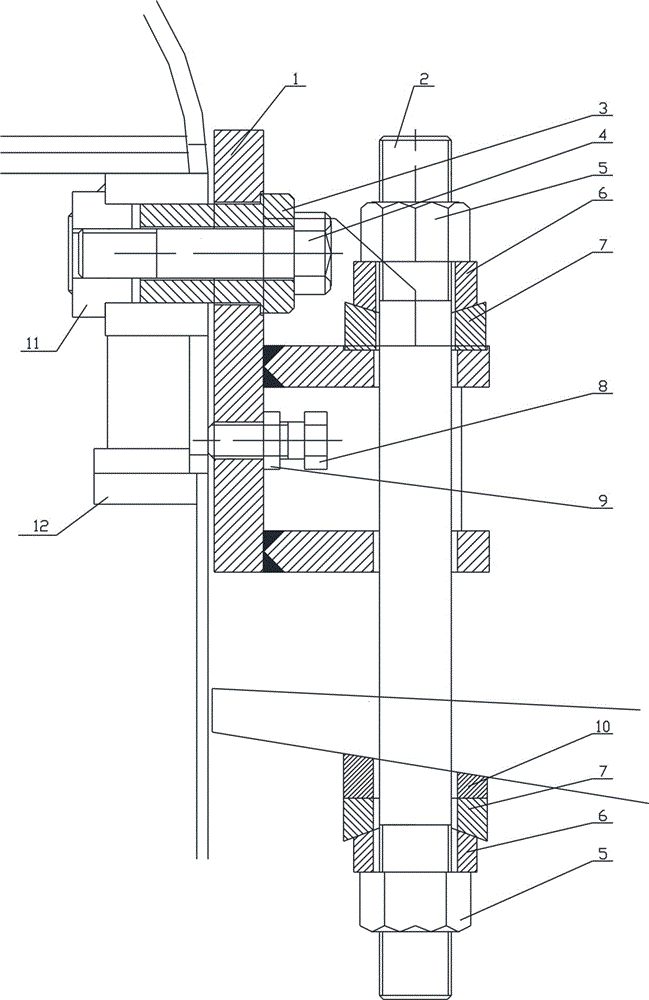

[0023] A process for leveling the runners of large-scale units, establishing a mathematical model with runners, suspensions, runner chambers, etc. as samples, combined with the calculation function of the excel table, changing the manual calculation in the process of runner leveling to the automatic calculation of the table , the result is directly displayed on the angle that each hanging nut needs to rotate. The program sets the angle output value with direction: when the hanging nut goes down clockwise, it is positive when the corresponding blade elevation increases, and when it is counterclockwise, it corresponds to the blade elevation decreases. Negative, thus greatly improving the leveling efficiency of the runner.

[0024] Mathematical model principle:

[0025] Such as figure 1 As shown, there is any line segment OA in the XOY plane with length d. The included angle between OA and the X direction is θ, draw a vertical line to the Y axis through point A, and the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com