Rectangular tube profile with flange

A technology for rectangular tubes and profiles, applied in the direction of slender components, building components, etc., can solve the problems of low material utilization rate and non-standard rectangular tube manufacturing, so as to improve performance and utilization rate, improve customer satisfaction, and improve utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

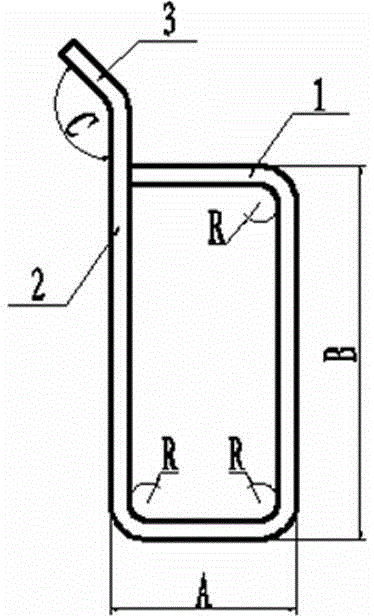

[0015] Such as figure 1 The shown rectangular pipe profile with flanging includes a pipe body 1, the pipe body 1 is in the shape of a rectangular pipe, the side 2 of the pipe body 1 extends upward, and the top of the side 2 is provided with an outward The flange 3, the angle C between the side edge 2 extending upward of the pipe body 1 and the top flange 3 is 90° or 135°, the width A of the pipe body 1 is 80 mm or 85 mm or 90 mm, and the upward extending The height B of the other side opposite to the side 2 is 140mm or 150mm or 160mm or 170mm or 180mm or 200mm, the inner angle of the pipe body 1 is an arc angle R, and the radius of the arc angle R is 8mm or 10mm or 12mm.

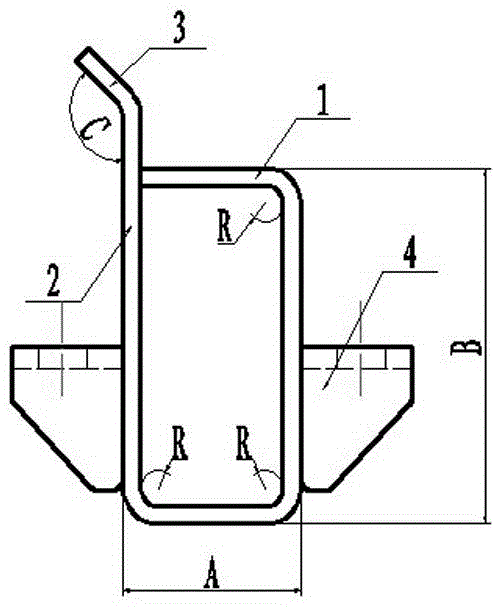

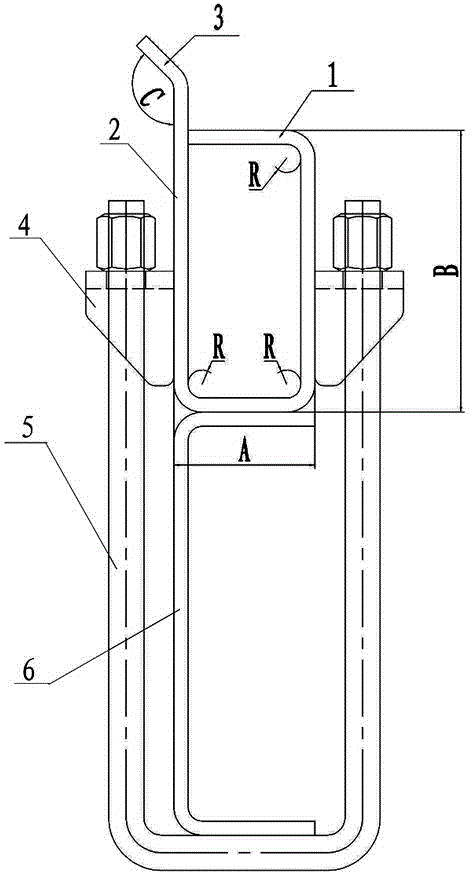

[0016] Such as figure 2 , image 3 As shown, the two side walls 2 in the height direction of the pipe body 1 are symmetrically welded with lifting lugs 4, and the lifting lugs 4 are provided with U-shaped bolts 5, and the pipe body 1 is installed in cooperation with the chassis girder 6 through the U-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com