A leak repairing structure of a gas cabinet and a leak repairing method thereof

A technology for gas cabinets and leaks, which is applied in the gas cabinet leak repair structure and its leak repair field, which can solve the problems of unfavorable surface treatment in the site environment, unintuitive quality of the repair agent, and humid environment of the gas cabinet, so as to reduce ignition Risk of gas, easy and quick surface treatment, effect of reducing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

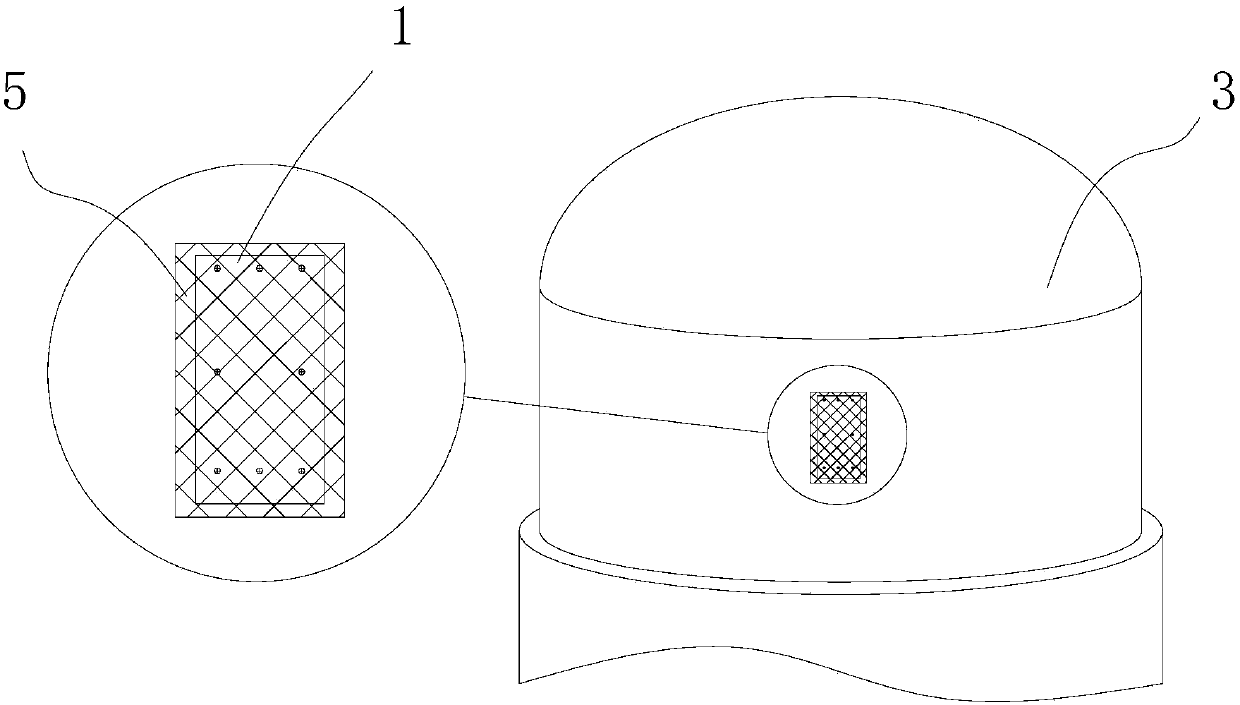

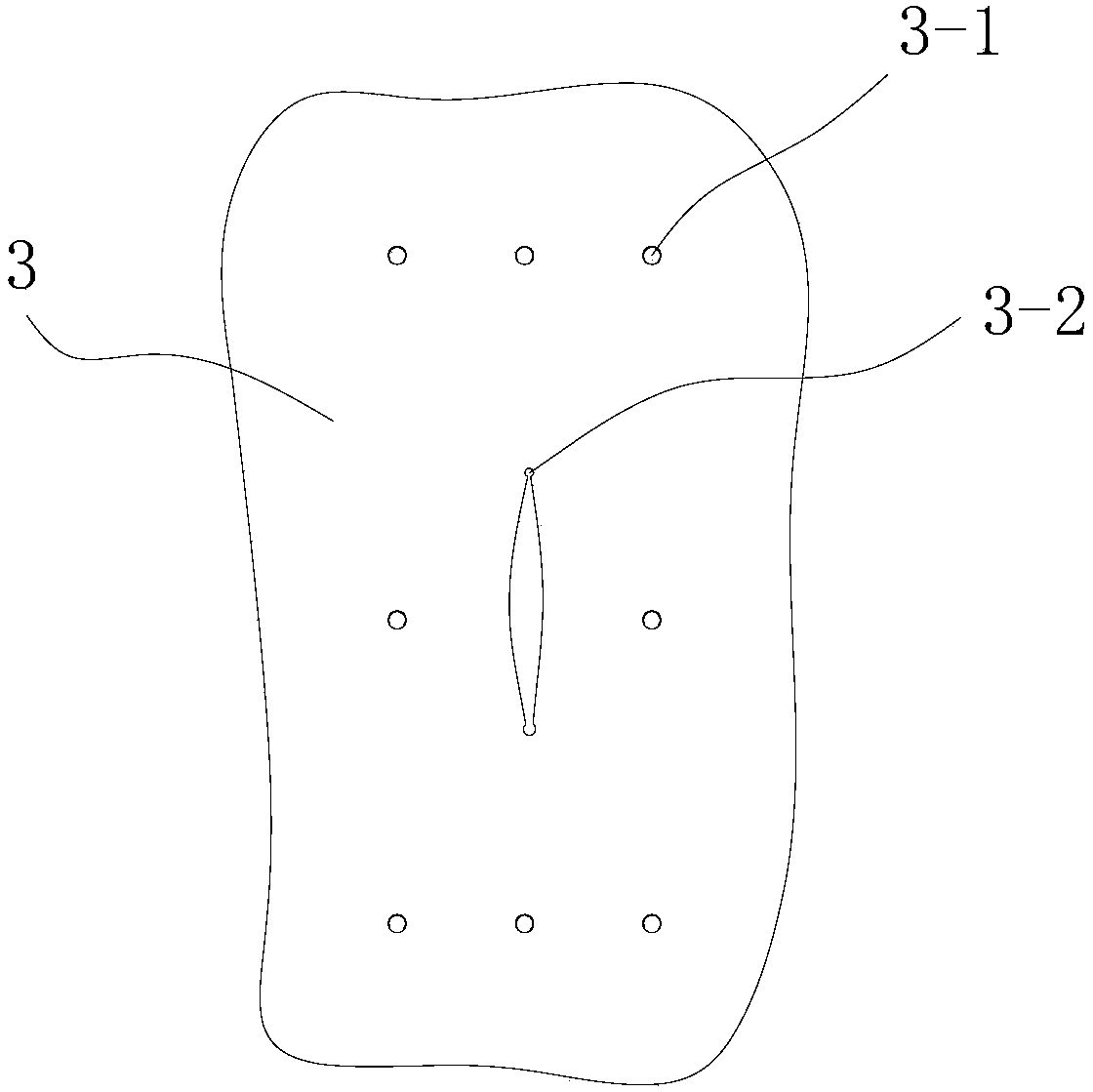

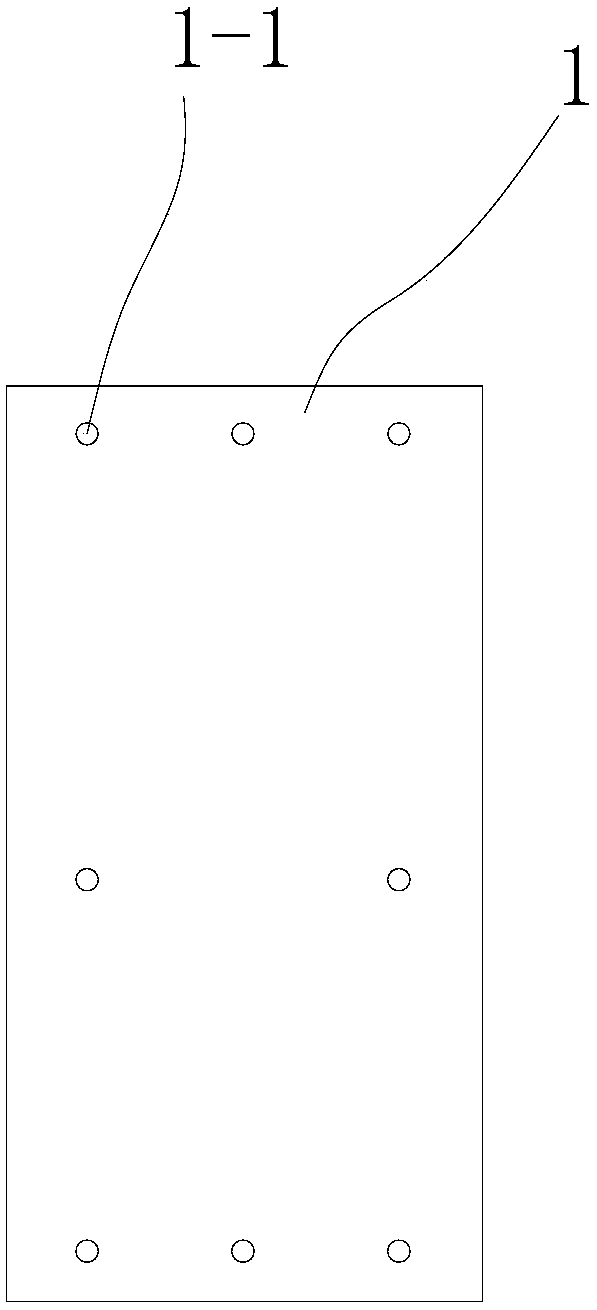

[0032] see Figure 1 to Figure 4 , a gas cabinet leak repair structure, comprising a gas cabinet 3, a repair template fixedly installed at the leak position of the gas cabinet; the repair template includes a repair template body 1, and the repair template body is provided with 2 to 8 diameters A through hole 1-1 of 4 to 8 mm, one side of the repair template body 1 is evenly coated with a silicone rubber layer 2, and the thickness of the silicone rubber layer after preliminary curing is not less than 10 mm;

[0033] A mounting hole 3-1 is processed around the leakage point of the gas cabinet 3 corresponding to the through hole position on the repair template body 1, and an internal thread is provided on the inner peripheral surface of the moun...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap