Rotary machinery fault feature extraction method based on self-adaptive wavelet energy

A technology of rotating machinery and wavelet energy, which is applied in the testing of mechanical components, measuring devices, testing of machine/structural components, etc., and can solve problems such as constant deviation, non-adjustable, and misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

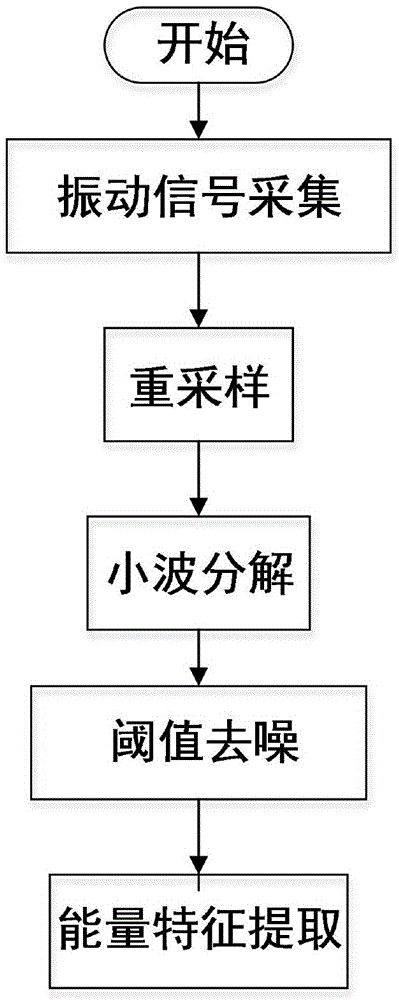

[0043] The inventive method has following realization steps:

[0044] Step 1: Vibration signal acquisition.

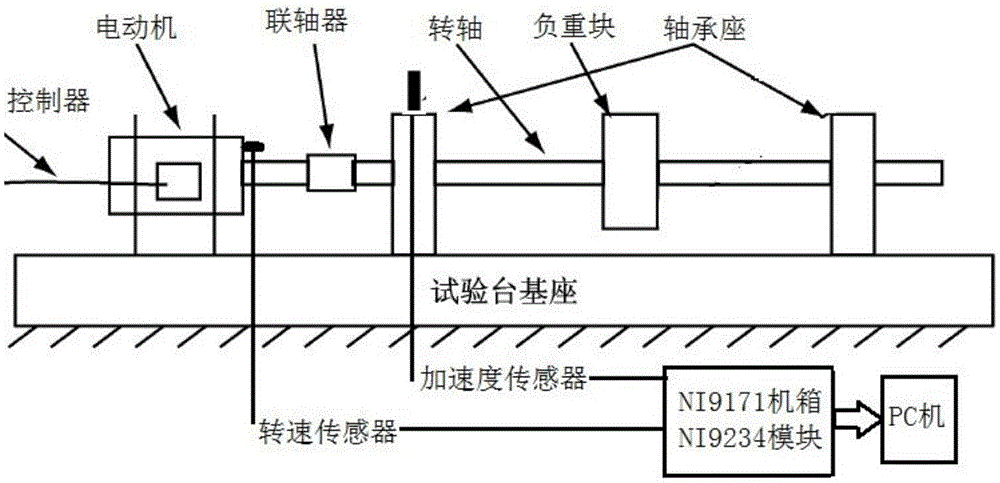

[0045] Use the MFS mechanical failure comprehensive simulation test bench to simulate the operation of the fan, such as figure 2 As shown, an acceleration sensor is installed on the bearing seat, and a photoelectric tachometer is installed on the rotating shaft, and the NI9234 module and the NI9171 portable chassis are used to cooperate with the slave sensor to collect vibration signals. The sampling rate is f s The normal vibration signal of the rotor and the three types of rotor fault signals of unbalance, misalignment and loose bearing seat are collected respectively, and the rotor rotation frequency is f n .

[0046] Step 2: Resample the signal.

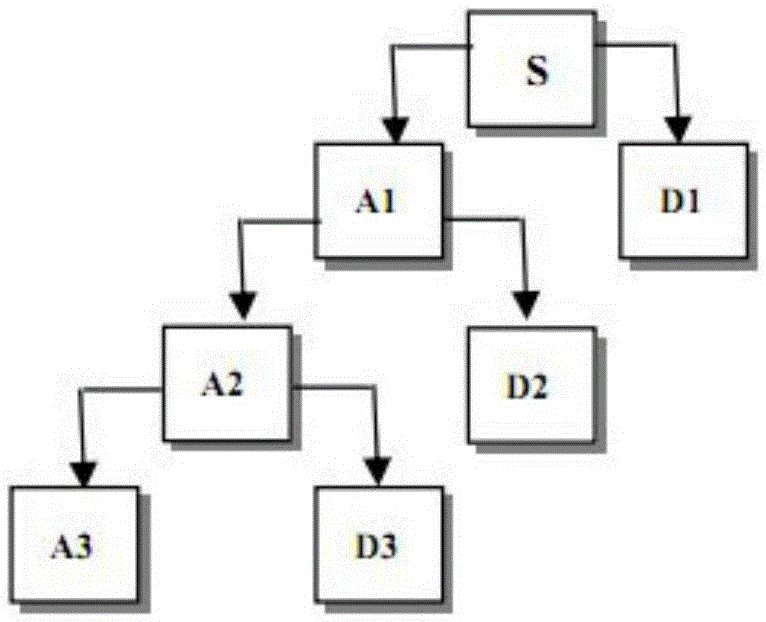

[0047] First, the input signal x(t) is scaled by f n transformation, for x(f n t) in time interval Δt s Sampling is equivalent to the original signal x(t) with Δt s / f n sampling at intervals. According to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com