Catenary Operation Status Safety Monitoring and Analysis System

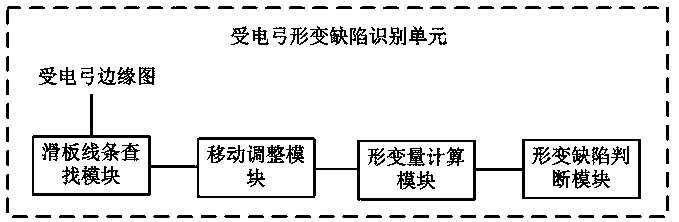

A technology for safety monitoring and operation status, applied in the field of catenary, which can solve problems such as low efficiency, needing skylight time, and inability to simulate operation status.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

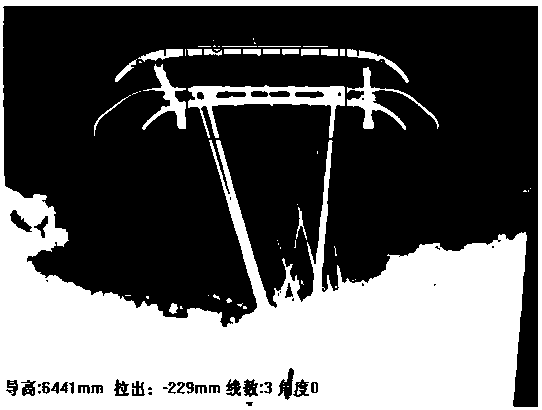

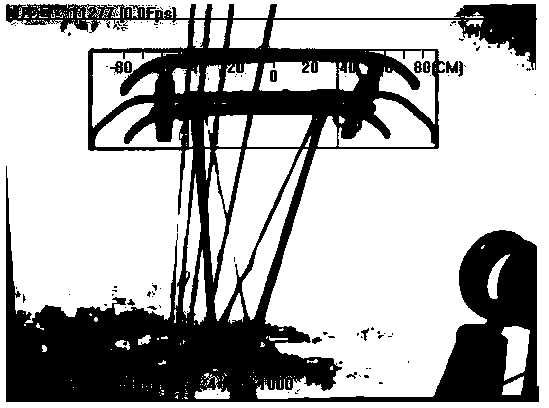

[0216] Embodiment one, such as Figure 11 Position the strut assembly as shown:

[0217] First, find the left edge of the pillar part: traverse the binary image line by line from left to right, scan the downward fan-shaped area of each pixel in each row, and there are n pieces in the downward fan-shaped area with the pixel For the downward scanning line segment with the point as the origin, count the number L1 of black pixels on the left and the number R1 of white pixels on the right of each downward scanning line segment in the downward fan-shaped area. When the number L1 and the number R1 account for the corresponding downward scanning When the length of the line segment is a certain proportion, it is determined that the downward scanning line segment in the downward fan-shaped area is the left edge of the pillar component.

[0218]Second, find the suspected right edge of the pillar component: After finding the left edge, continue to scan the downward fan-shaped area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com