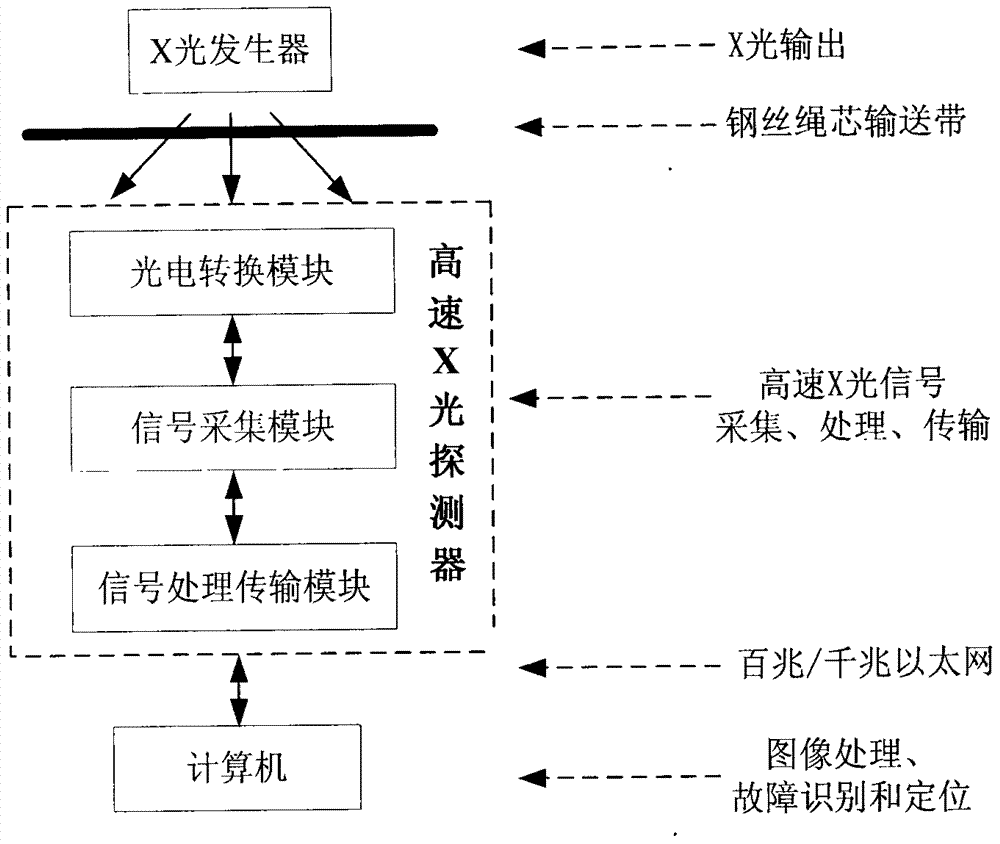

An fpga-based x-ray detector acquisition control and signal processing device for steel cord conveyor belt

A signal processing device and optical detector technology, which is applied in the direction of measuring device, program control, computer control, etc., can solve the problem of unsatisfactory correction effect, and achieve the effect of accurate online monitoring, low complexity, and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

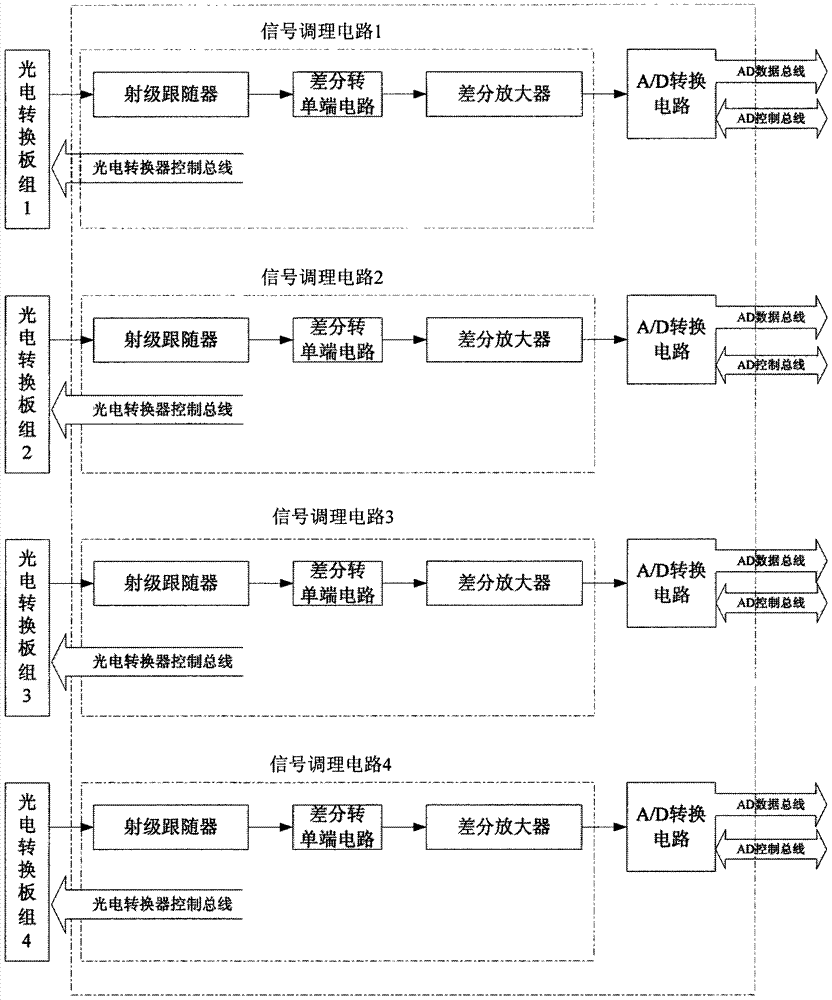

[0087] The FPGA-based steel cord conveyor belt X-ray detector acquisition control and signal processing device of the present invention is applied to a conveyor belt steel cord X-ray detector containing 4 sets of photoelectric converters.

[0088] image 3 Shown is the block diagram of the signal acquisition module in the detector. The photoelectric conversion module contains 4 sets of photoelectric conversion boards. Each set of photoelectric conversion boards connects 4 (maximum 8) photoelectric conversion boards in series to generate 1 serial electrical signal; 4 sets of photoelectric conversion boards generate 4 serial electricity The signal is sent to the signal acquisition module at the same time for amplification, filtering and A / D conversion to increase the signal acquisition rate. The signal conditioning circuit is composed of an emitter follower, a differential-to-single-ended circuit and a differential amplifier; the A / D conversion circuit uses TI’s AD7667 chip, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com