Infrared sensing electronic whiteboard

An infrared sensing and electronic whiteboard technology, which is applied in the input/output process of electronic digital data processing, instruments, and data processing, etc. The structure is not complicated and the cooling effect is balanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment, content of the invention will be further described:

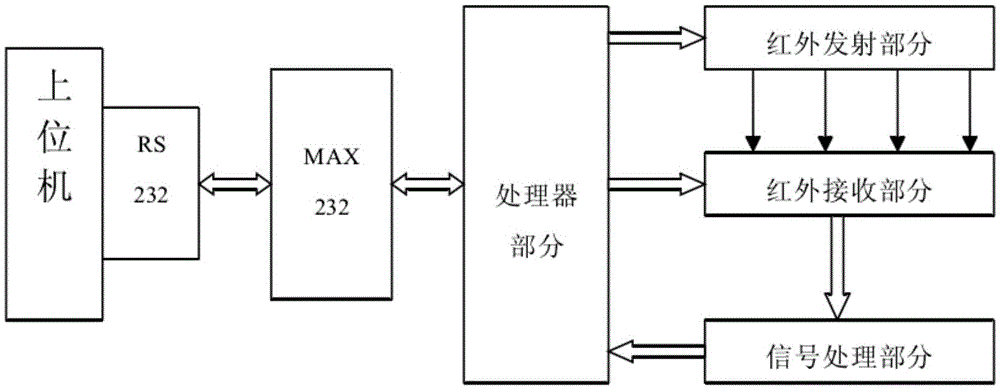

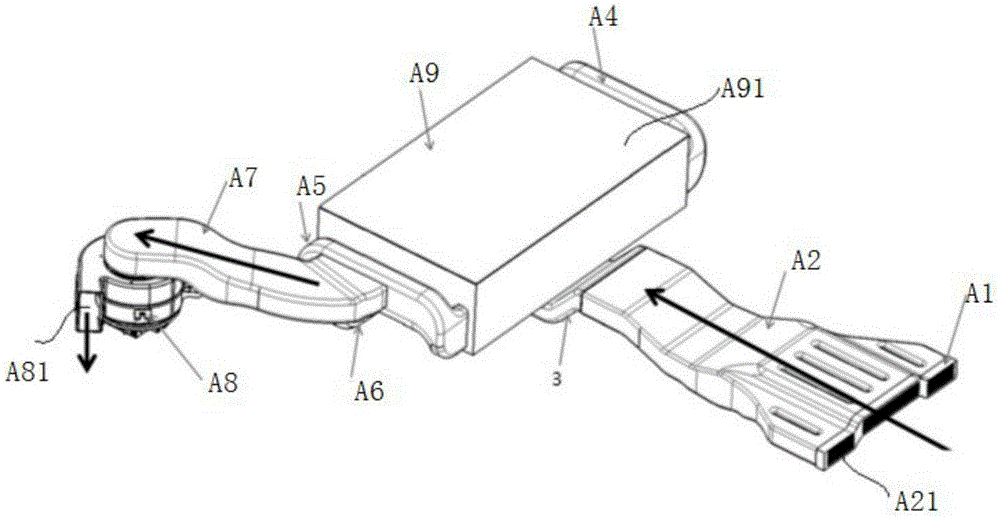

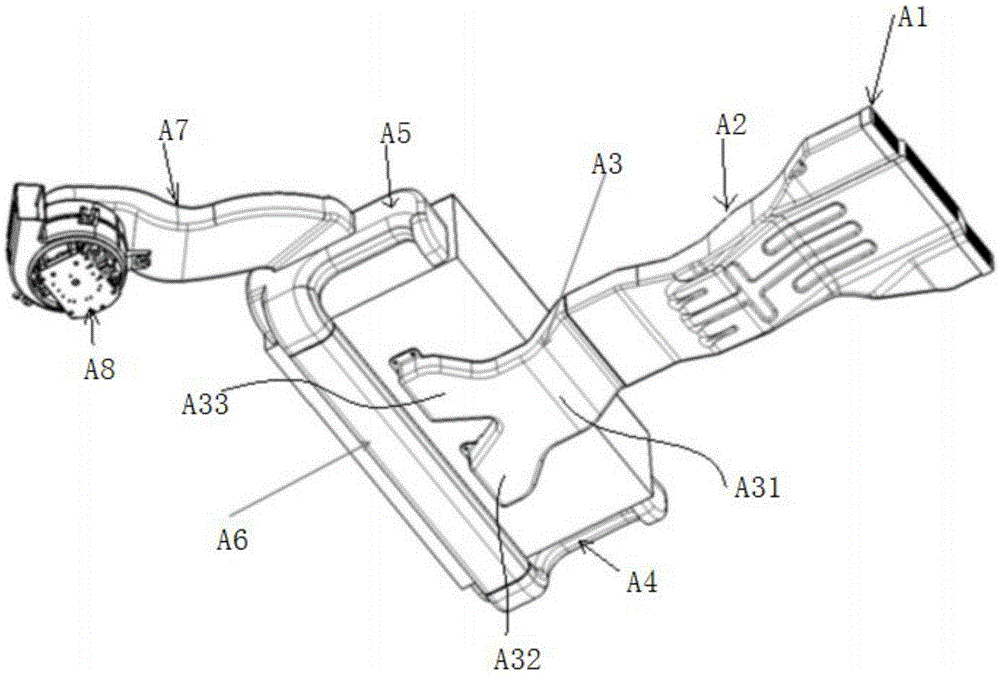

[0021] refer to Figure 1-Figure 7 As shown, the infrared sensing electronic whiteboard includes a host computer with an RS232 interface, the RS232 interface is connected with the MAX232 chip, and the MAX232 chip is also connected with the processor part, and the processor part is also connected with the infrared emitting part, The infrared receiving part and the signal processing part are connected, and the infrared emitting part, the infrared receiving part and the signal processing part are connected sequentially, and the infrared receiving part includes several infrared receiving tubes, and the processor part, the infrared emitting part, the infrared The receiving part and the signal processing part are set in the control cabinet A9;

[0022]In addition, it also includes a cavity passage for feeding gas, a cavity passage for releasing gas, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com