Direct-pressing capo

A capo, direct pressure technology, applied in the field of capo, can solve the problems of low conversion efficiency of spring elastic force, insufficient safety, damage to musical instruments, etc., and achieve the effect of good work effect, not easy to slip, and high energy efficiency value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

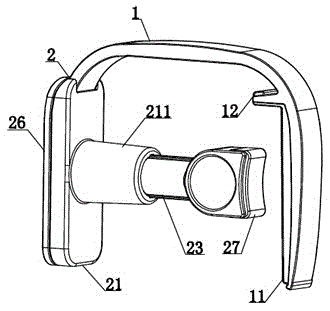

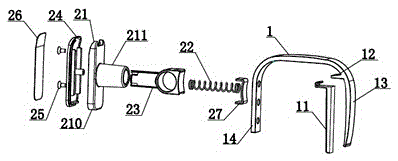

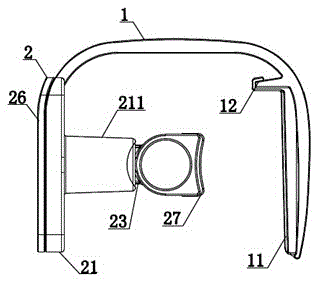

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a direct pressure capo includes a U-shaped main clip body 1 and a thrust assembly 2. The first end arm 13 of the U-shaped main clip body 1 is used to press the string of a stringed instrument. The U-shaped main clip The second end arm 14 of the body 1 is equipped with a thrust assembly 2, and the thrust assembly 2 pushes the back of the stringed instrument to the first end arm 13 of the U-shaped main clamp body 1 by thrust, and the first end arm 13 of the U-shaped main clamp body 1 Squeeze the strings of stringed instruments tightly.

[0023] Preferably, the inner side of the first end arm 13 of the U-shaped main clamp body 1 is used to press the strings of the stringed instrument, and a buffer pad 11 for pressing the string ends is provided.

[0024] Preferably, the first end arm 13 of the U-shaped main clip body 1 is used to press the string end of the stringed instrument and is provided with a stop pie...

Embodiment 2

[0033] Preferably, the thrust unit 22 is a metal shrapnel potential energy component.

Embodiment 3

[0035] Preferably, the thrust unit 22 is a hydraulic potential energy component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com