An inner loop reactor for water detritiation and its realization method

A realization method and technology of internal circulation, applied in radioactive purification, nuclear engineering, etc., can solve the problem of inability to quantitatively and accurately control the content of tritium in low-tritium water and tritium-containing hydrogen gas, difficulty in controlling the residence time of gas-liquid phase in the exchange column, Pt-based The catalyst is expensive and other problems, and achieve the effect of compact structure, simple structure and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

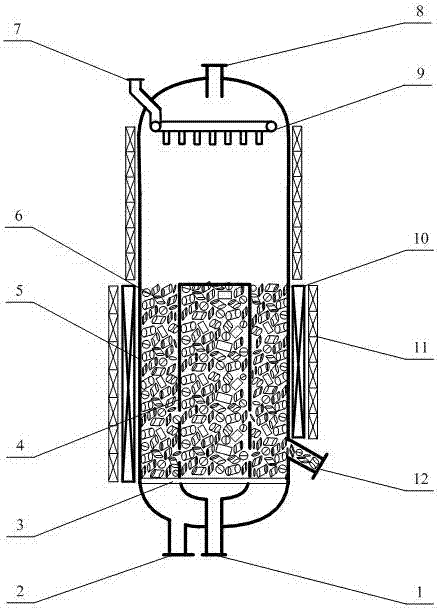

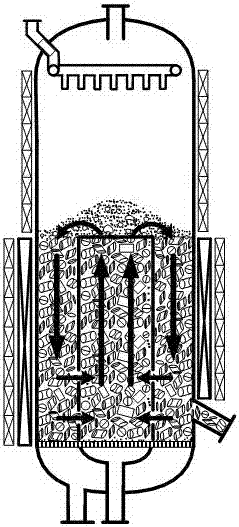

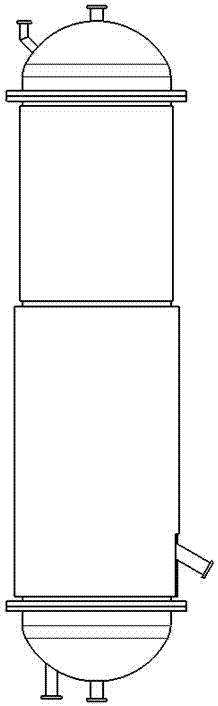

[0034] Such as figure 1 As shown, the present invention provides a novel reactor that can realize detritiation of water. The present invention includes a top cover, an outer cylinder 5, an air inlet pipe 1 in a central area, an air inlet pipe 2 in an annulus area, a sintered plate 3, a The diversion cylinder 4 of the diversion hole, the θ ring filler coated with a hydrophobic catalyst 6, the tritium-containing water inlet pipe 7, the tritium-containing hydrogen gas exhaust pipe 8, the annular pipe distributor 9, the low-tritium water outlet pipe 12 and the control temperature system.

[0035] The top cover, the outer cylinder 5, the guide cylinder 4 and the hydrogen inlet buffer chamber constitute the main body of the inner circulation reactor, wherein the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com