Relay cover pressing device

A relay and gland technology, applied in the field of relay processing, can solve the problems of difficult to guarantee the quality of relay products, single production equipment, and low degree of automation, and achieve the effects of product reliability, high production efficiency, and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

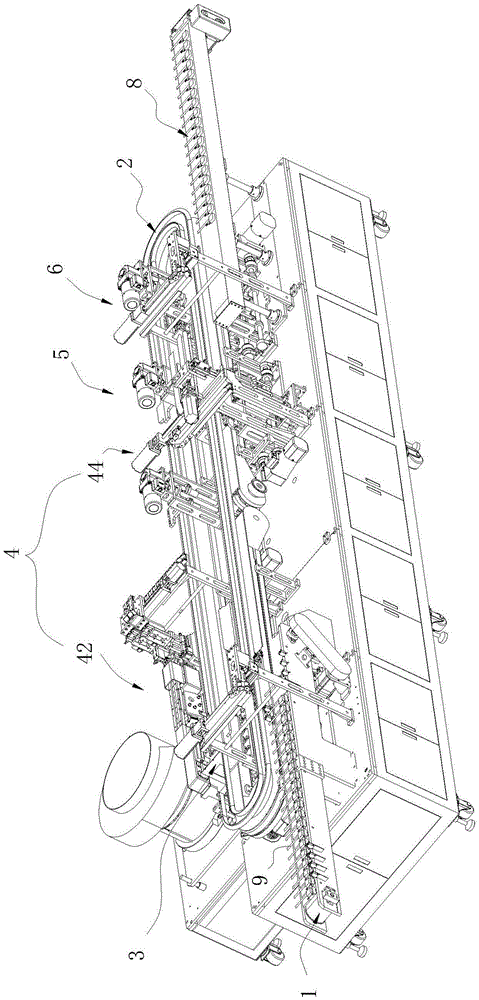

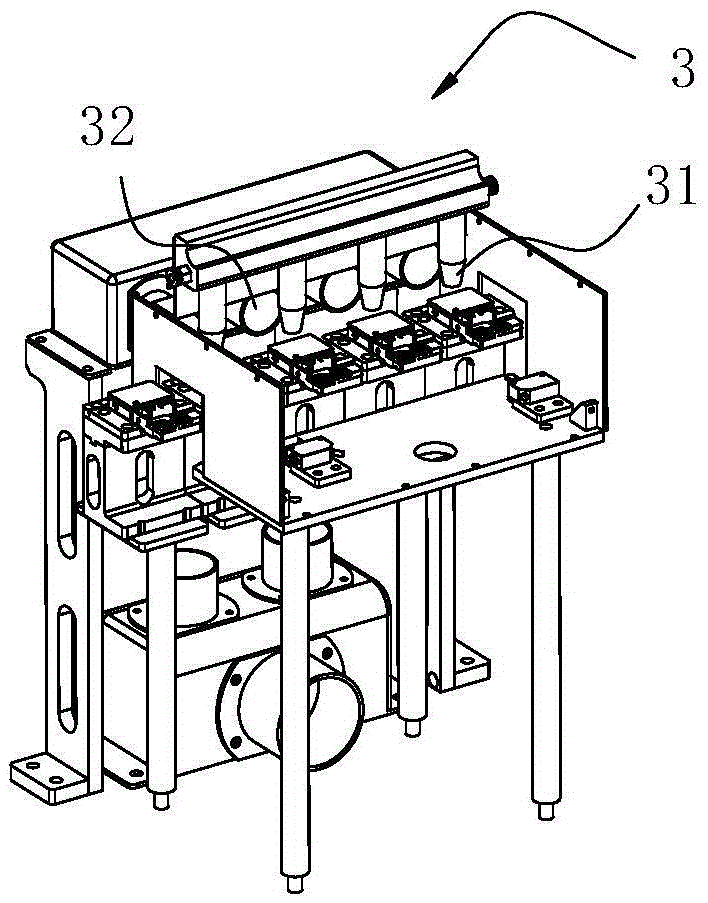

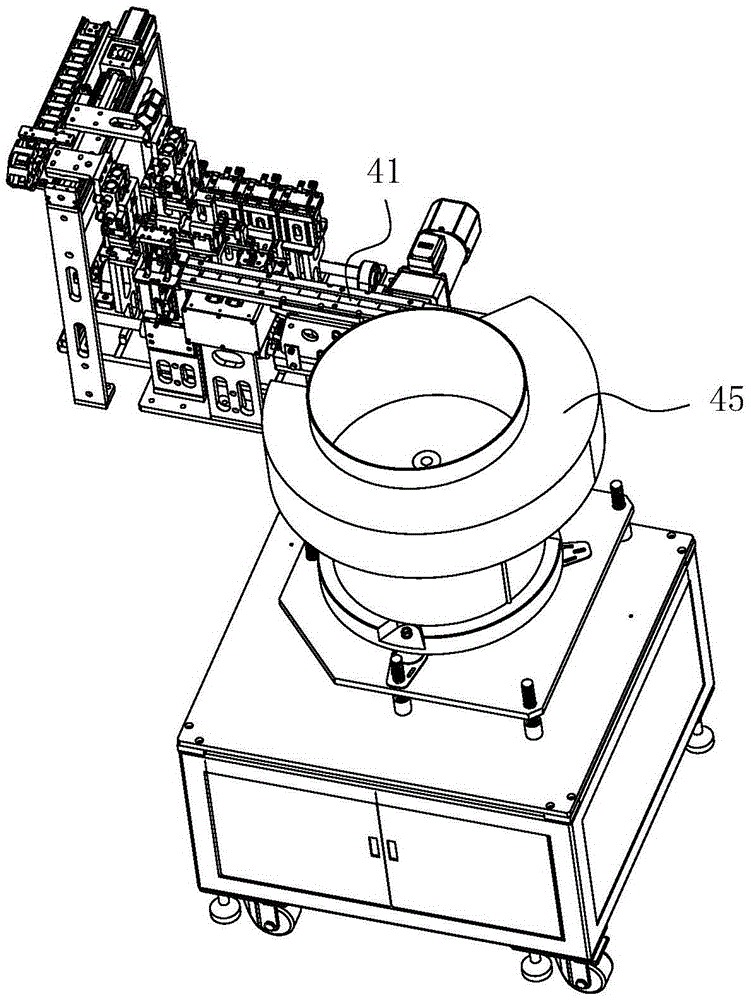

[0042] Such as Figure 1-14 As shown, a comprehensive testing machine for relays described in this embodiment includes: a looping cable 2 and a loading cable 1 and a blanking cable 8 arranged on the side of the looping cable 2, the loading cable 1 and the looping The position where the backguy 2 is connected is provided with a feeding manipulator, the position where the unloading backguy 8 is connected with the circulating backguy 2 is provided with a blanking manipulator, and the circulating backguy 2 between the loading manipulator and the described unloading manipulator On the side, a relay capping device 4 and a relay performance testing device are sequentially arranged along the running direction of the circulating pull wire 2 .

[0043] The circulating backguy 2 includes a backguy track and a backguy drive motor for driving the movement of the backguy on the backguy track. The backguy track is an annular double-layer structure with an opening, and the backguy drive motor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap