Super junction device and corner structure layout design and manufacture process thereof

A super-junction device and layout design technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as insufficient improvement of the overall withstand voltage, and achieve the effect of improving the withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with accompanying drawing:

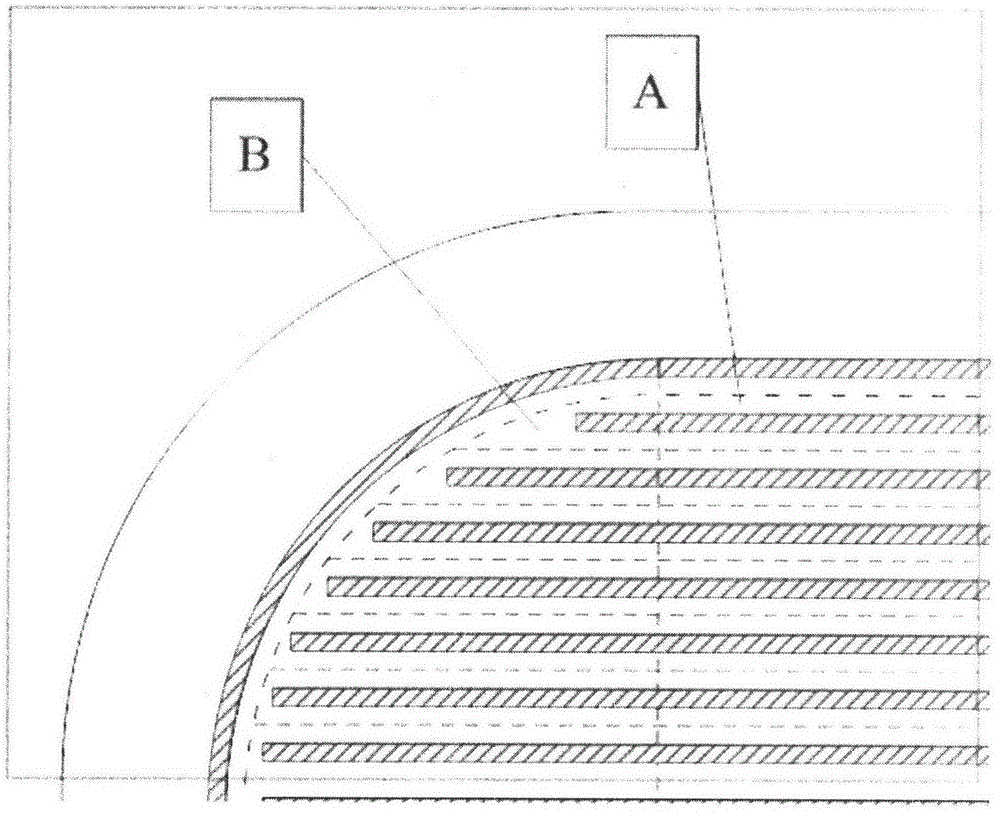

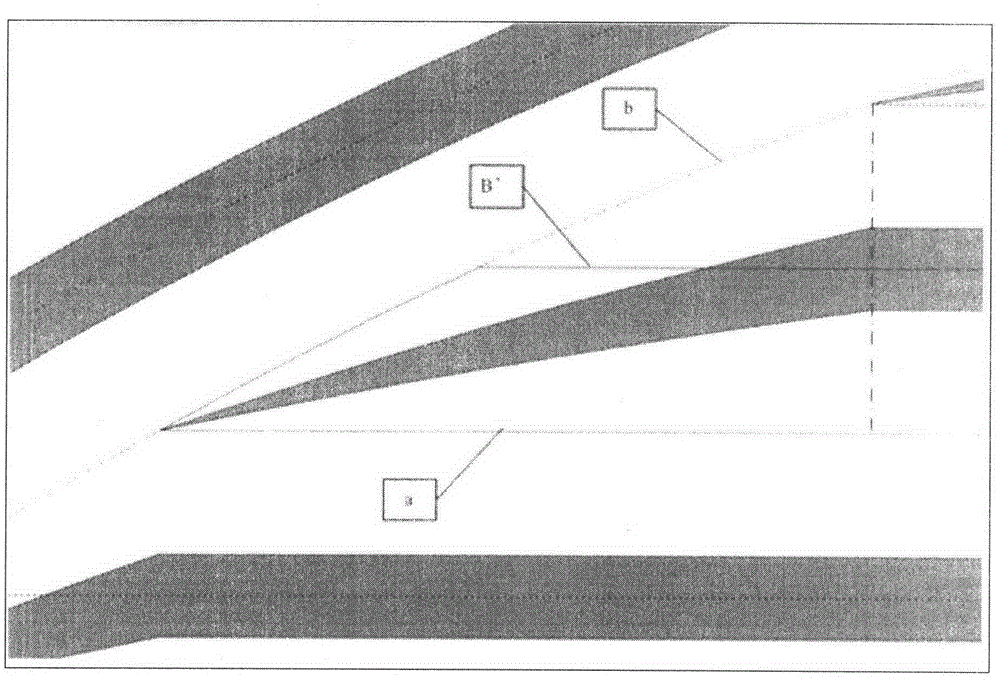

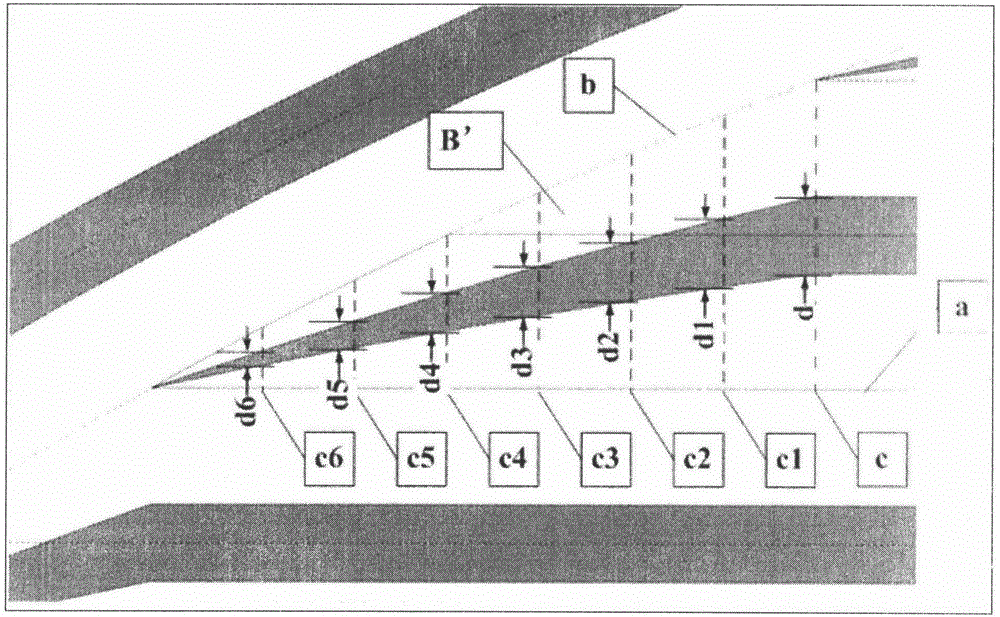

[0046] Such as figure 1 and figure 2 As shown, the corner structure of the superjunction device of the present invention, in the corner region, the boundary of the repeating unit of the cell changes from a straight line (a boundary) to a curve (b boundary), and the doping pattern of the second conductivity type (shading Part) will be optimized and adjusted according to the distance in the vertical direction between the a boundary and the b boundary, so that the area ratio of the first conductivity type doping and the second conductivity type doping in the B' region is the same as that of the ordinary cell region ( figure 1 The ratio in the region A of ) is almost the same, so that the superjunction device can achieve almost the same withstand voltage value as that of the ordinary cell region at the corner.

[0047] Such as Figure 3-Figure 5As shown in the layout design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com