Conveying device for agriculture

A conveying device and agricultural technology, which is applied in the field of agricultural machinery, can solve problems such as low efficiency, jamming, and pipelines that are susceptible to external interference, and achieve the effects of reliable operation, avoiding jamming, and simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

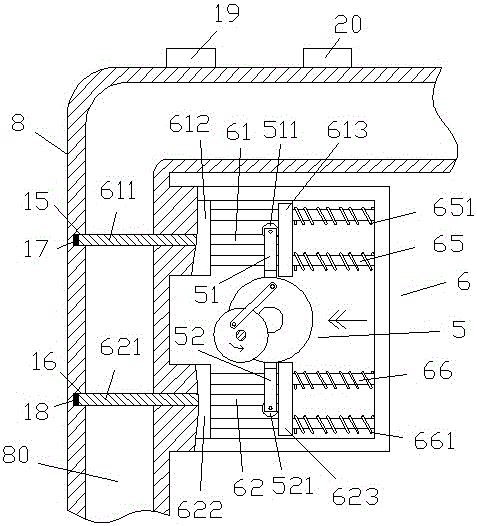

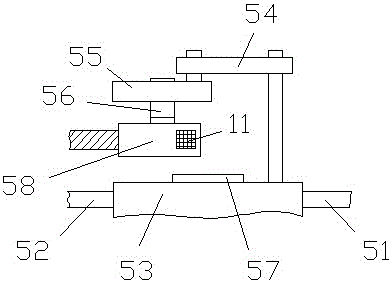

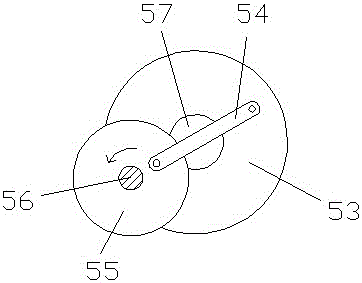

[0010] Combine below Figure 1-4 The present invention will be described in detail.

[0011] A conveying device for agriculture according to an embodiment, comprising a material supply pipeline 8 fixed to the frame and a supply control component 6 fixedly connected to the material supply pipeline 8, the material supply pipeline 8 receiving from the material supply bin The material that is discharged by applying supply pressure, the supply control part 6 includes an upper cut-off plate 611 and an upper cut-off plate 611 that can extend telescopically into the inner passage 80 of the material supply pipeline 8 to cut off the inner passage 80 respectively. The lower cut-off plate 621, the upper cut-off plate 611 is fixedly connected with the upper drive convex plate 613 slidably carried on the two upper guide columns 65 through the upper cut-off plate connecting portion 61, the right side of the upper drive convex plate 613 Pressed by the upper elastic pressing member 651 sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com