Automatic Calibration Method and System for Scanning Accuracy of Ultrasonic Probe

An ultrasonic probe and automatic calibration technology, applied in ultrasonic/sonic/infrasound equipment testing/calibration, ultrasonic/sonic/infrasonic diagnosis, sonic diagnosis, etc. problems, to overcome scanning errors, improve quality, improve convenience and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below with reference to the embodiments shown in the accompanying drawings. However, the embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

[0046] It should be noted that the automatic calibration method for the scanning accuracy of the ultrasonic probe of the present invention is mainly applied to ultrasonic diagnostic equipment.

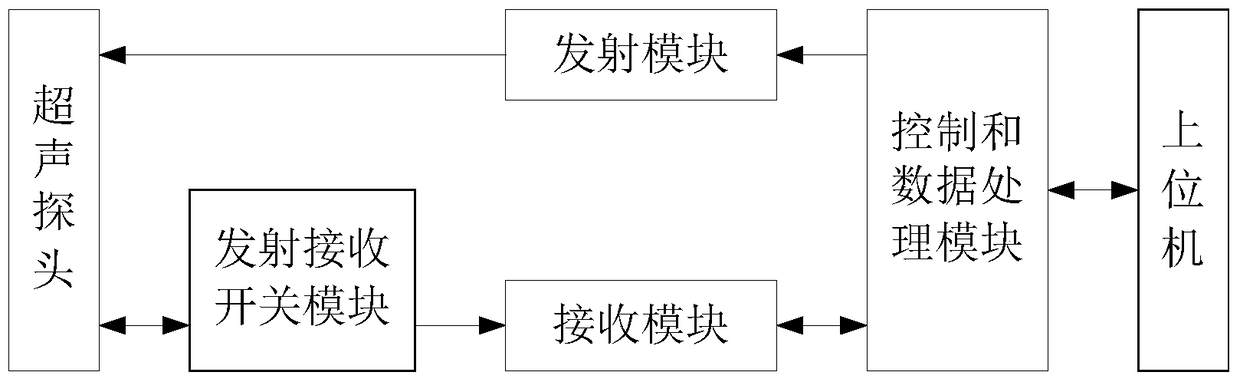

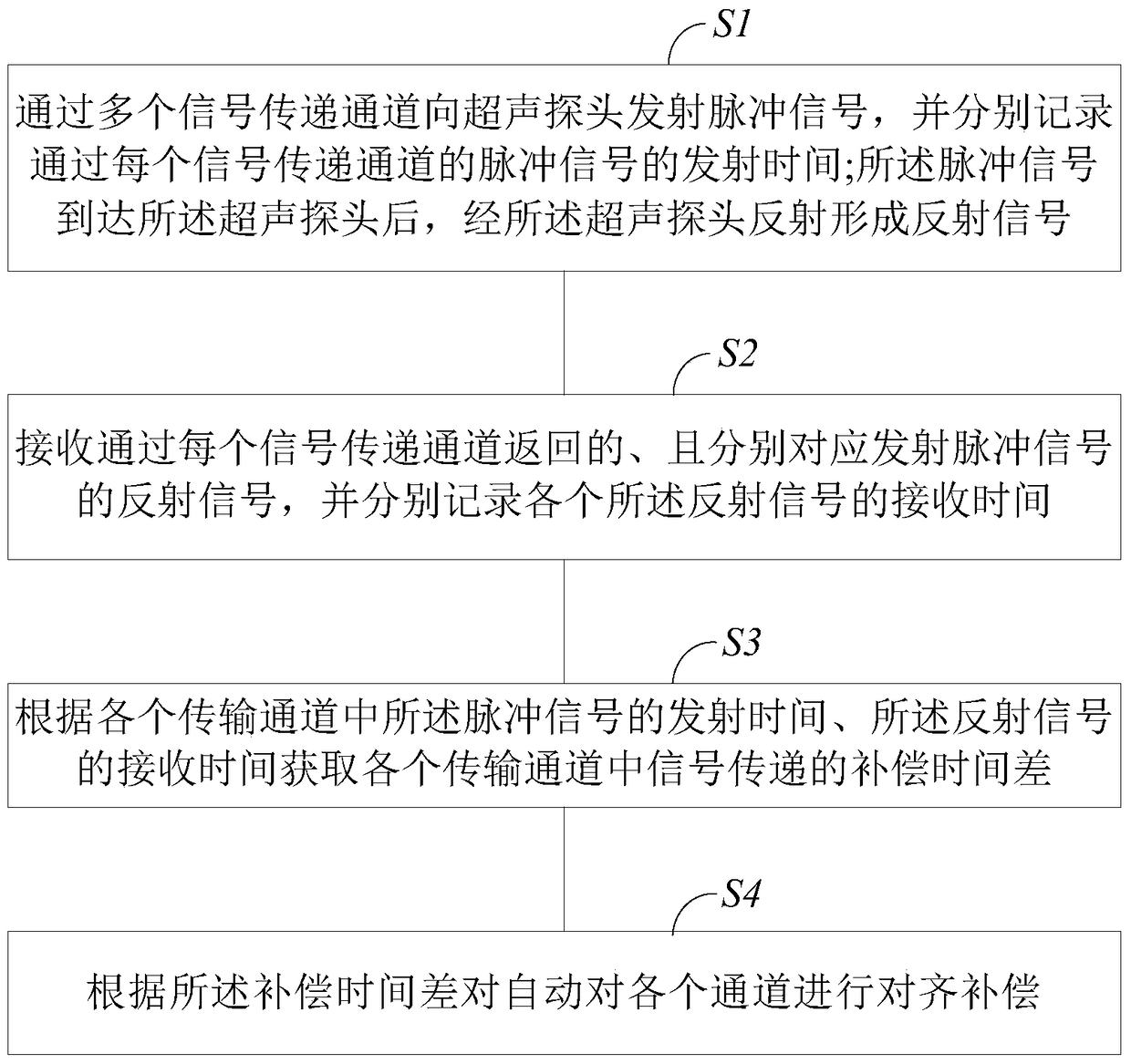

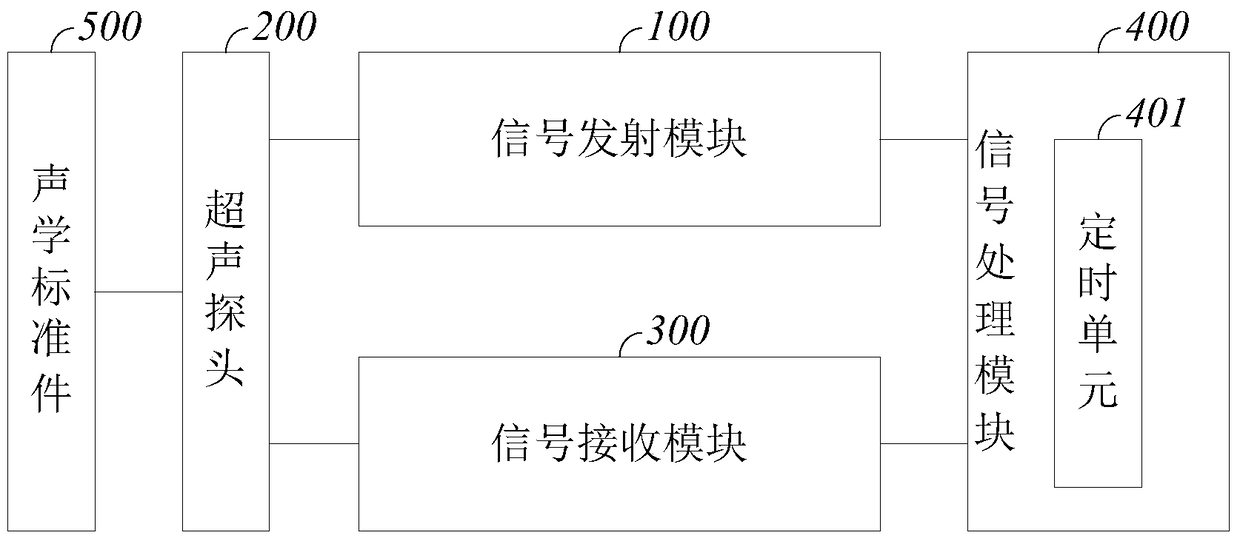

[0047] During the working process of the ultrasonic diagnostic equipment, it needs to send a pulse signal to the ultrasonic probe, and send it to the object to be tested through the ultrasonic probe. Further, the pulse signal is reflected by the surface of the ultrasonic probe to form a reflected signal, and returns to the ultrasonic diagnostic equipment for subsequent processing. processing to diagnose the analyte.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com